2000W Laser Metal Cutter

Shijiazhuang Lechan Packaging Co., Ltd / 2022-06-23

- Application:Home Appliance, Food Machinery, Aerospace Industry, Woodwork Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Desktop

- Laser Classification:Free Electron Laser

=== Base Info ===

- Model NO.:VLF1530LN

- Laser Technology:Laser Control Fault Cutting

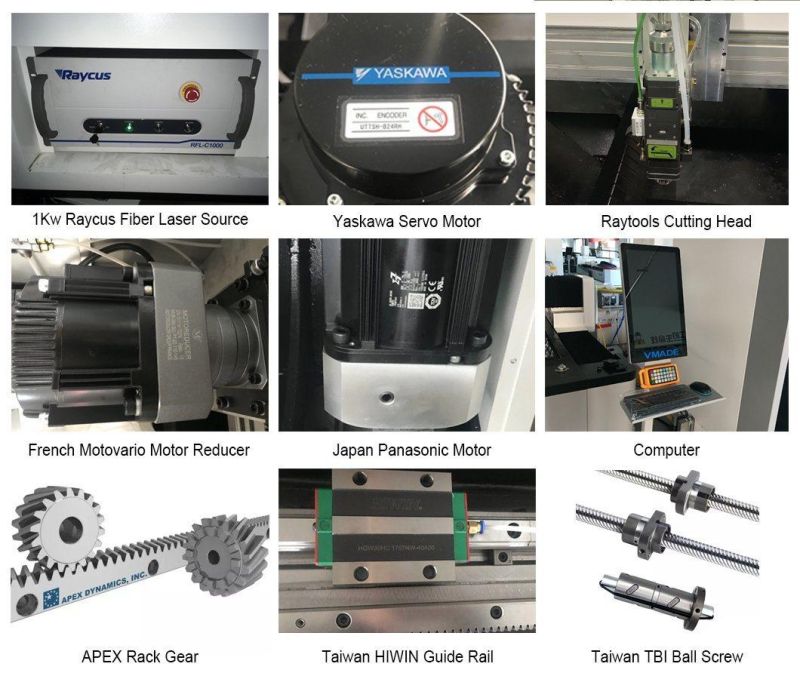

- Laser Head Brand:Raytools Bt240,Bm109,Bm111,Bm114

- Laser Source Brand:Raycus,Ipg

- Servo Motor Brand:Japan Yaskawa Servo Motor and Driver

- Control System:Cypcut

- Rack Gear:Yyc,Apex Dural Rack Gear

- Cooling Mode:Tongfei Water Chiller

- Transport Package:Wooden

- Specification:VLF1530LN

- Trademark:VMADE

- Origin:China

- HS Code:8456110090

- Production Capacity:500,Month

=== Description ===

Basic Info.

Model NO. VLF1530LN Laser Technology Laser Control Fault Cutting Laser Head Brand Raytools Bt240/Bm109/Bm111/Bm114 Laser Source Brand Raycus/Ipg Servo Motor Brand Japan Yaskawa Servo Motor and Driver Control System Cypcut Rack Gear Yyc/Apex Dural Rack Gear Cooling Mode Tongfei Water Chiller Transport Package Wooden Specification VLF1530LN Trademark VMADE Origin China HS Code 8456110090 Production Capacity 500/MonthProduct Description

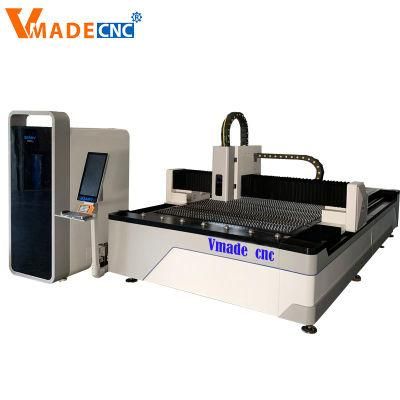

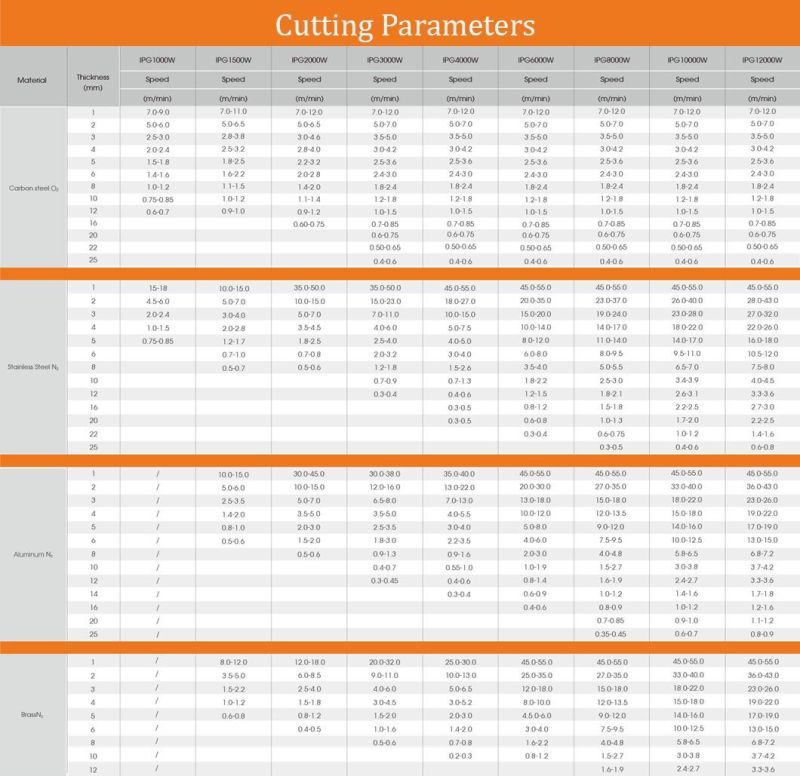

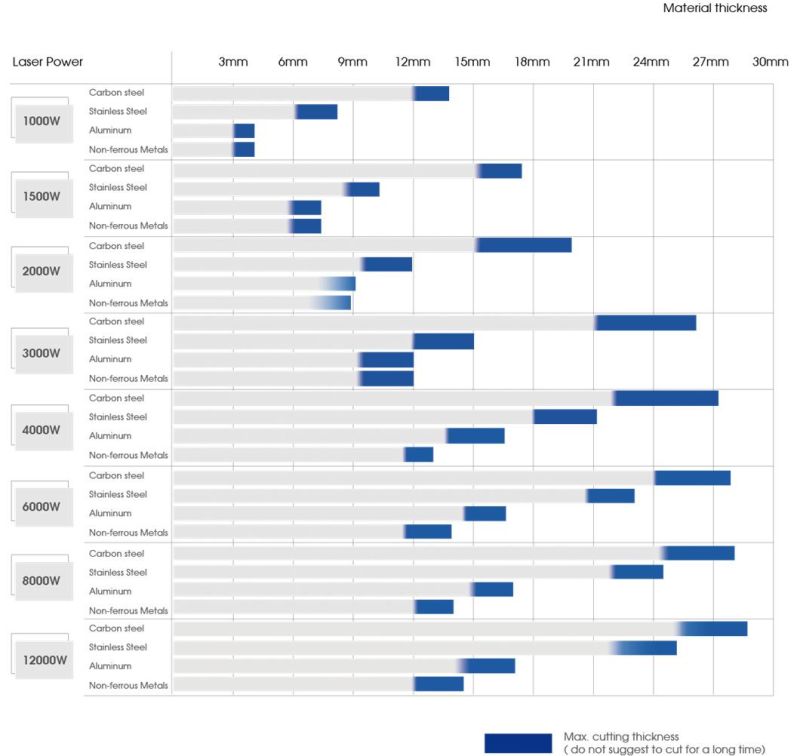

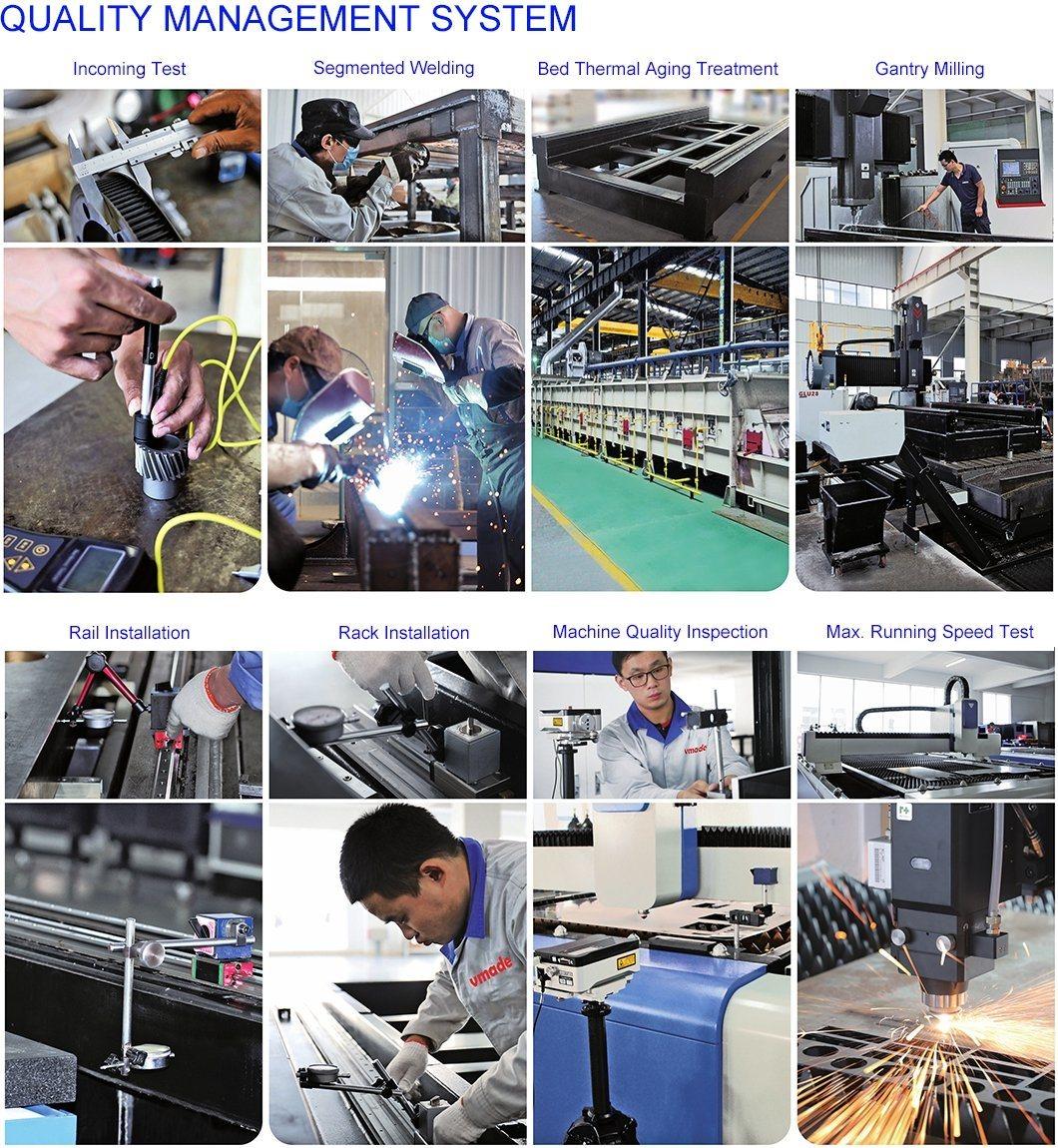

Fiber Laser Metal Cutting Machine 1000W 2000W 3000W VLF3015N is fast speed mild steel cnc fiber laser cutting machine with 3000*1500mm working area, which consist of machine tool, motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts, so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis of aluminium stainless steel sheet cutting machine adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23