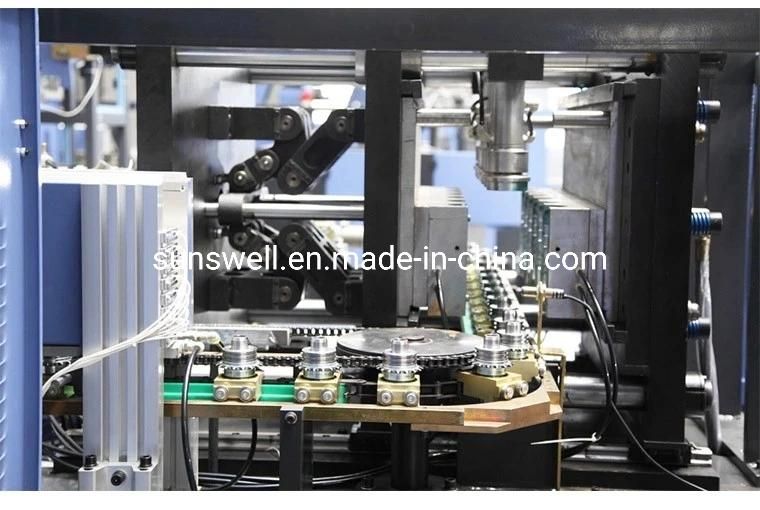

6cavity Automatic Blow/Blowing Molding/Moulding Machine for Pet Water Bottle

Qingdao Powerful Machinery Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Model

SSW-9000

Bottle type specification

Cavity

6

Theory output

8000-9000

Max.volume

2.25L

Bottle mouth maximum overall diameter

28-38mm

Bottle biggest diameter

105mm

Bottle maximum height

330mm

Power specification

Light tube quantity

48pcs

Light tube power

1.5KW

Maximum heating power

72KW

All electric machine installation

75KW

Actual consumption

40%--70%

Air pressure specification

Work pressure

7-9kg/cm2

Low-pressure gas consumption

1000L/min

Blow bottle pressure

25-35kg/cm2

Higher -pressure gas consumption

3000Ltr/min

Air pressure specification

Work pressure

5-6 kg/cm2

Temperature range

10ºC

Consumption

8000kcal/hr

Forzen water flow

138L/min

Machine specification

Machine size

5.5x1.6x1.9

Machine weight

4500KG

Product Description

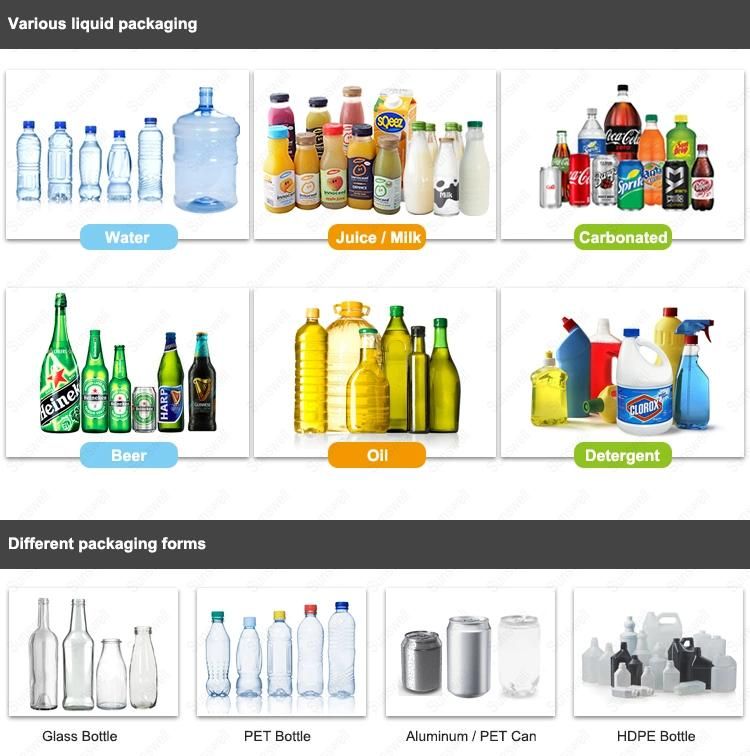

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Automatic High Speed Water Bottle Blowing Molding Machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

1). Stable performance with advanced PLC.

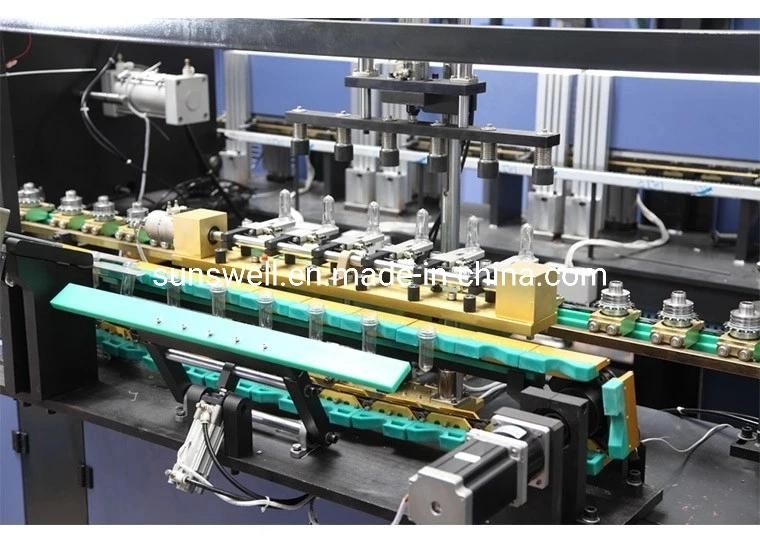

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Safereliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11). Low costhigh efficiencyeasy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws.

13). Easy for you to installtest and start up.

14). Low rejection rate: less than 0.2 percent.

-----------------------------------

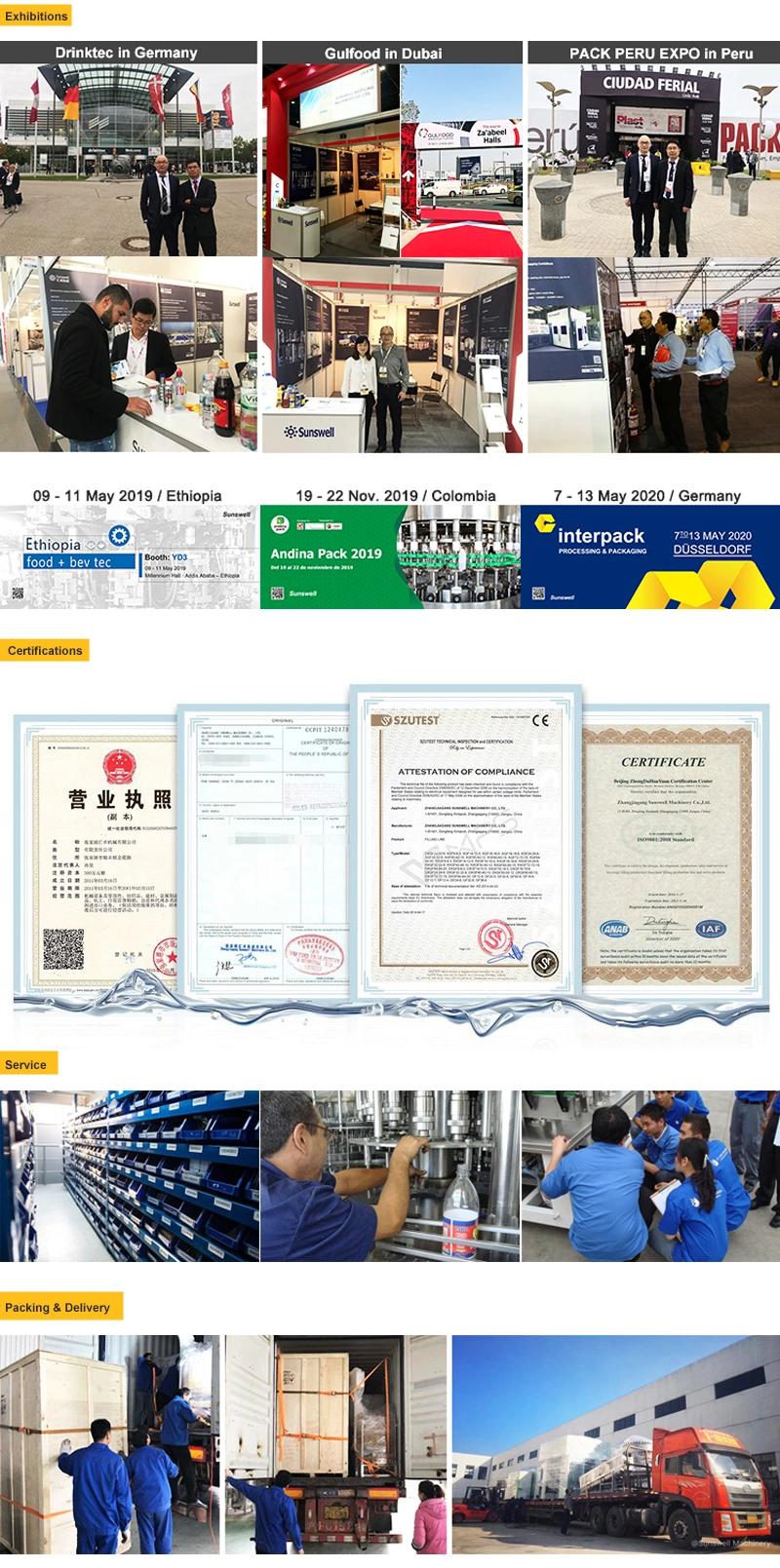

About Sunswell:

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: ensure you to reach business goals with most optimized planning.

Why choose us?

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

(4)Serve customers over 50 countries and regions worldwide

Advantage:

No matter whether you're a newcomer or a sectoral expert - we have the specialists who can provide the comprehensively can-do support you need for planning a new facility in terms of not only actual beverage production, but also filling, packaging, utilities and logistics. In closely responsive consultation with you, from a multiplicity of possible options, we select the technologically and commercially most effective variant, handle the design and planning work, and bring the project to a successful conclusion at your chosen location. Sunswell is not only the consultant here, but also takes responsibility for executing the entire project.

Related Products:

FAQ:

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed. Or you can arrange engineers to study in our factory.

You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Welcome to click "SEND" below for more information!

Contact:New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23