Small Fruit and Vegetabel Freeze Dryer

Shandong Haishengyu Plastics Industry Co., Ltd. / 2022-07-04

- Capacity:1kg-500kg

- Customized:Customized

- Power:1.1KW

- Voltage:220,380V

- Type:Complete Plant

- Transport Package:Standard Export Packing

=== Base Info ===

- Origin:China

- Trademark:GY

- Specification:50kg-5000kg

- Model NO.:FD

- Production Capacity:50kg-5000kg

=== Description ===

Raw material

fresh vegetable

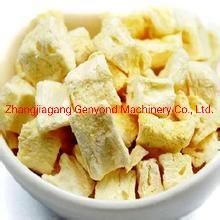

End products

vegetable &fruit chips

Processing capacity

50-5000kg/h

Drying methods

Frying / Vacuum frying / Hot air drying / Vacuum freeze drying

Terminal package

plastic bags, cans, etc.

Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present. Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components. The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking. This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc.

Working principle of vacuum freeze dryer

Instead of traditional vaporization dehydration method, the vacuum freeze drying technology is dehydrate products by sublimation directly from ice to vapor. During the Freeze drying process, the materials will be frozen to -18°c, then move into the vacuum drying tank for dehydration, automatic control system will set the vacuum and heating temperature according to the freeze drying cirve of each products to maintain the proper circumstances for FD processing. The materials stay in frozen status during the drying process and water vapor will be condensed on the surface of cold trap coils to absort the water out from the materials.

Application

The vacuum freezing and drying machine can be widely used in various fields, such as vegetables, fruits, condiments, seafood, biological products, medicine, beverage, specimen, etc.

Technology Parameter

Parameters

Model

FDGY-0.5

FDGY-10

FDGY-20

FDGY-50

FDGY-100

FDGY-150

FDGY-200

FDGY-280

Drying area

(m2)

0.5

10

20

50

100

150

200

275

Mean dehydrating amount (kg/h)

5-6

100

200

500

1000

1500

200

2750

Size of material tray

(m)

310×540×30

745×635×30

435×555×30

540×635×30

Number of material tray (pcs)

3

21

80

144

288

480

576

792

Size of pot

(M)

1.5×1.6×1.6

φ1.4×2.1

φ1.8×2.4

φ2.4×4.8

φ2.4×8.9

φ2.4×12.8

φ2.4×16.6

φ2.4×21.9

Operation vacuum

(pa)

13.3~200

26.6~200

Heating plate T

(°C)

Normal temperature~+120°C

Electric heating

(Kw)

2

21

40

Steam consumption

(Kg/h 0.7Mpa)

140

270

450

540

750

Cold load consumption

(Kw)

1.5

21.6

36

90

180

280

360

490

Installed power

(Kw)

6.5

55.8

104.5

41.2

69.7

92.5

117.5

125.5

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23