Polycrystalline Diamond Compact for Mining and Petroleum Bits

Laizhou Dechen Machinery Co., Ltd. / 2022-06-27

- Type:Polycrystalline Diamond Compact

- Surface Finishing:Polishing

- Blade Material:Diamond

- Usage 1:Gauge Pads of Drill Bits

- Usage 2:Drilling Bit Cutters and Stabilizer

- Usage 3:Coal Mining Core Drill Bits for Geotechnical

=== Base Info ===

- Model NO.:RT008

- Transport Package:Plastic Box

- Specification:Polycrystalline Diamond layer, tungsten carbid

- Trademark:Reetec

- Origin:Wuhan

- HS Code:82071910

- Production Capacity:300000pieces,Year

=== Description ===

Remarks:Customized Specifications Upon request

Quality Control

Reetec achieved ISO certification in 2010. REETEC'S certified quality program ensures the best possible product consistency and uniformity for each of our product, and guarantees the delivery of defect free products and 100% customer satisfaction.

REETEC has set up a new performance test laboratory, and uses world-class testing and inspection equipments both for product development and for quality control. We subject our cutters to rigorous testing, to ensure REETEC cutters meet the highest quality standards.

Vertical Turret Lathe (VTL) Heavy Wear Test

REETEC's premier test apparatus is the large VTL used for performance and high-energy testing of PDC cutters.

The VTL machine is equipped to perform both wet and dry PDC tests, in granite and composite cement samples. As the PDC cutter cuts through miles of granite, we monitor temperature and cutting forces, and measure cutter wear volume periodically and at the end of the test. This allows us to evaluate cutters' aggressiveness, efficiency, abrasion resistance and thermal stability.

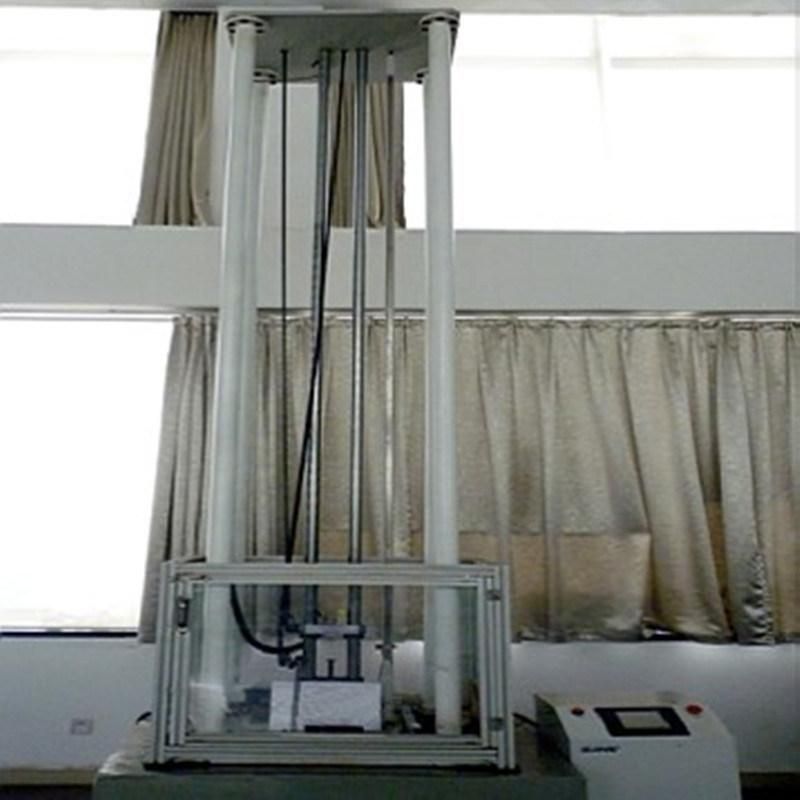

Impact Resistance Test

The drop impact test evaluates the impact strength of our PDC cutters. This test emulates the type of loading that might be encountered when the bit transitions from one formation to another or experiences lateral and axial vibrations.

Drop impact testing is part of PDC development. It screens cutters to make sure they are not too "fragile". While this is an industry-standard test, it should be noted that the drop impact test does not duplicate all impact-related downhole conditions. Other test development efforts for impact resistance testing are underway.

Simulated Brazing Test

Simulating the actual brazing environment, we run three simulated brazing cycles for thermal proof testing. After each brazing cycle we check for cracks and delamination using dye-penetrant testing and ultrasonic C-Scan. Brazing tests insures that the customer will not experience problems in brazing PDC cutters into bits, and in repairing PDC bits.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23