Breakfast Cereals Corn Flakes Bread Crumbs Core Filled Puffs Snacks Baby Food Making ...

Jiangsu Itech Labels Technology Co., Ltd. / 2022-07-04

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Warranty:2 Years

- After-sales Service:Engineers Available for Machine Installation

- Automatic Grade:Automatic

=== Base Info ===

- Usage:Breakfast Cereals, Snacks

- Operator:3-5

- Consumption:Low

- Guarantee:2 Years

- Service:Filed Installation.

- Output Capacity:150kg,H, 300kg,H

- Operation:Automatic

- Finished Products:Corn Flakes, Cereals and Puffs Snacks

- Price:Factory Price

- Raw Materials:Corn Powder

- Electronic:ABB

- Inverter:ABB

- Motor Brand:Siemens

- Automatic:Fully

- Customized:Customized

- Application:Breakfast Cereals

- Model NO.:SLG65,SLG70,SLG85

- Installed Capacity:200kw

- Transport Package:Standard

- Trademark:Saibainuo

- Origin:China

- HS Code:84388000

=== Description ===

Basic Info.

Model NO. SLG65/SLG70/SLG85 Application Breakfast Cereals Customized Customized Automatic Fully Motor Brand Siemens Inverter ABB Electronic ABB Raw Materials Corn Powder Price Factory Price Finished Products Corn Flakes, Cereals and Puffs Snacks Operation Automatic Output Capacity 150kg/H, 300kg/H Service Filed Installation. Guarantee 2 Years Consumption Low Operator 3-5 Usage Breakfast Cereals, Snacks Installed Capacity 200kw Transport Package Standard Trademark Saibainuo Origin China HS Code 84388000Product Description

Twin screw extruder corn flakes cereals puffs snacks machine1.Equipments formulating of corn flakes making machine:

Mixer → SLG70/85 extruder → air conveyor → flaking machine →air conveyor → Three-layer oven → elevator → salt cooking machine →sifter → elevator → flavor roller → melting machine → sugar sprayer( air compressor) → elevator → five-layer oven → cooling conveyor → (wrapping machine)

1).This processing line can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrient-flour, and baby food and so on.

1).This processing line can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrient-flour, and baby food and so on.2).The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

3).The forced lubrication system, by guaranteed equipment transmission longer life.

4).Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

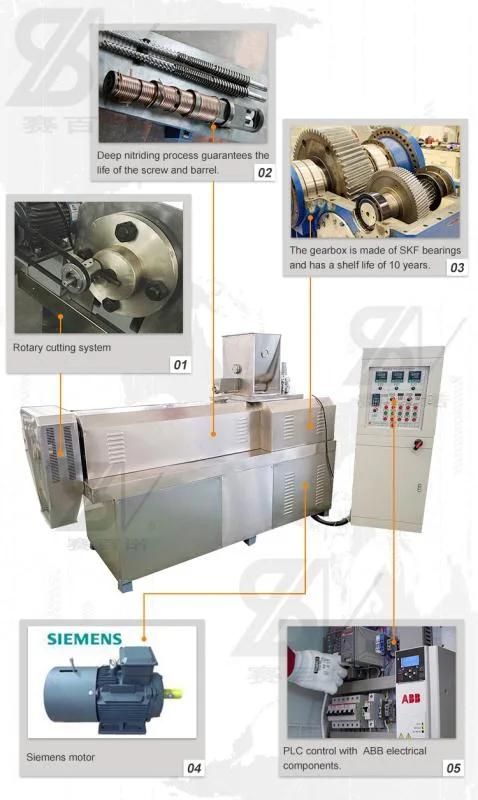

5).Twin screw extruder has the following part:

feeding system, extrusion system, cutting system, heating system, lubricating system, driving system, control system

6).Extruder Details

Twin screw extruder for Cereal breakfast Corn flakes making machines adopts the extrusion technology.

After the cereals is extruded, the products will become bigger, puffy texture, crisp taste, starch form, increasing the water dissolve, easy to absorb by human, thus, it is popular in the world.

2. Products and raw materials:

Corn flour, rice flour, wheat flour, soya flour, millet flour, corn grits, and other different grain flours.

3. Finished corn flakes, breakfast cereals, corn puffs snacks, bread crumbs,baby food.

The same extruder by changing mould and adding necessary auxiliary equipment, it could make puffs snacks, bread crumbs, baby food and core filling snacks. The samples photo as bellow:

A. Corn flakes as bellow:

B. Breakfast cereals

C. Puffs snacks

D. Bread crumbs

E.Baby powder food

4. Corn flakes making machine Flow chart:

Raw material formulating → Mixing → Extruding, inflating cutting into ball shape → cooling conveying → Air conveying → tablet compressing → Drying → Flavoring → Conveying → Drying → Cooling conveying → (Packing)

5.Technical parameters of Corn flakes making machine:

| Model Parameters | SLG70 corn flakes manufacturing machine | SLG85 corn flakes manufacturing machine |

| Installed capacity | 166KVA | 263KVA |

| Power | 110Kw | 200Kw |

| Output | 120-150kg/h | 240-320kg/h |

| Dimension | 45×3×4m | 48.5×5×4m |

6. Corn flakes machine in Saibainuo factory

7. Saibainuo factory introduction, Corn flake machine packing and delivery

1).Saibainuo company and factoryWe have got several certificates including CE and we are 8 Years Alibaba Golden Supplier.Saibainuo has a comprehensive manufacturing program offering equipment and systems to customers in extruded snack food processing machinery and allied industries. We can supply individual items of equipment or complete factory layouts and lines, which are custom-built to meet the requirements of customers. snack maker machine

Full functional department:Research and development department,Technical design team,manufactur team,Inspection team,after sale service team. snack maker machine

Factory standing area:33000 square meters Workshop standing area:20000 square meters.

Office area:4 floor with 600 square meters.

2). Breakfast cereals corn flakes machine packing and deliverying

To packing corn flakes machine: Firstly clean the equipment and using the Standard

packaging film wrap them carefully.

Second, Precision measurement equipment size, make independent wooden packaging of each machine.

Our purpose to keep machine safe during delivery .

Also can satisfied your needs, about inspection & quarantine , CIQ, fumigation , etc.

3).Our service before and after corn flakes machine purchasing.

We provide complete installation and operation manual in english for all the machines supplied by us.customer can install and operate machines using the same.If needed,we can send our technician for the installation of the machines at customer's place on chargeable basis.

Our expert technician can install the machines and take the trial production as per the requirement of the customer.

The technician could train operators at the customer's place to operate the machine,they also will train them for troubleshoot all the problems, so that later one they can manager everything easily without any problem.

After the installation,customer can take help from us any time in any of the following manner:

1.By calling our technician to get telephonic advice.

2.By sending mail to us to get the solution by mail.

3.To chat live with our technician to get online help.

4.To invite our technician to visit customer's place for troubleshooting,if needed.

8.Contact

How to find a stong partner in China?

1.Alibaba golden supplier for years. snack maker machine

2.Own a big factory which can produce at least 30 sets of machine per month.

3.Own it's self research and development department with many years experience in this industry.

4.Can provide you special designed machine as per your request,which can keep you make fresh products and lead the market. snack maker machine

5.A company can provide you professional pre-sale service,suitable quality machine,original qucik wear parts and satisfactory after sale service.

6.Choose suppliers with a Trad Assurance Amount granted (Based on trade history)

snack maker machine

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23