PVC Marble Sheet Board Extruder Machine

Xinzheng Lifa Abrasives & Abrasives Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

SJZ80/156 conical twin screw extruder

Screw and barrel

Screw Diameter 80/156

Screw Length 1800mm

Screw rotation speed 0-37 r/min

Material of Screw and Barrel 38CrMoAlA

type Hard tooth face, bevel wheel,gear grinding

Motor power 1.1 KW

Feeding speed regulator by variable frequency inverter

brand of inverter ABB ACS550

Motor Power 55KW AC motor

Speed adjusting ways by variable frequency inverter

brand of inverter ABB ACS550

Output Capacity 300-400kg/h

motor power 3Kw

hauling speed controlled by frequency inverter

roller clamp and releasing pneumatic driving

Length cutting pneumatic driving cutting.

Cutting control PLC automatic control

Auxiliary Machines

SRL300/600 Hot and cold mixer

3Roller High glossy UV coating line

Crusher

Pulverzier

Part3 Introduction of PVC marble sheet and profile

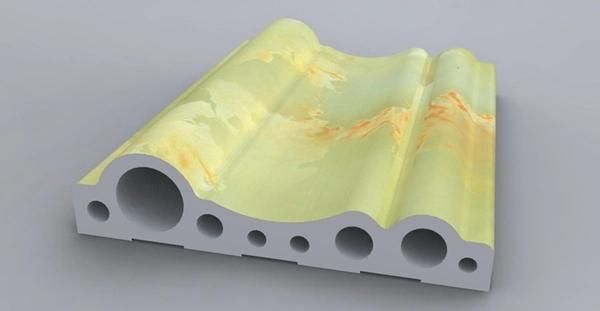

PVC marble-imitated decoration material, known as the PVC stone plastic, calcium plastic, is a new type building material, which consists of PVC resin-oatmeal, calcium carbonate, and a small quantity of plastic processing additives, plasticizing by special purpose equipment. In compliance with the national save energy and reduce consumption and comprehensive utilization of resources policy, PVC marble imitated decoration material is regarded as new type environmental decoration material which collects all the advantages of wood and stone. And it is widely used in interior decoration industry such as hotel, restaurant, KTV house mall meeting room, etc.

Features of the PVC marble sheet and profile

Green and environmental protection Formaldehyde-free, non-benzene, non stone radioactive substances, Non-toxic and harmless, also friendly to environment and harmless to humans.

Resourcezation of product material Main raw material is made up by natural stone powder(calcium carbonate), PVC resin or PVC reclaimed materials with wide raw materials sources.

Diversification and strong plasticity of product Imitation Marble product is artificially synthetic product, and can be produced into various material with different performance and shape, which has a realistic design by laminating, heat transfer printing, UV surface processing.

Durable, and long service life, with marble-imitated appearance and texture.

Fire proof, flame retardant, water proof and damp proof.

Quick to install, and can be used after bonding by environmental floor glue.

Recycling and reutilization, which matters to our natural resources and ecology environment.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23