HDPE Hollow Wall Spiral Winding Structured Wall Pipe Machinery

=== Base Info ===

=== Description ===

heat shrink sleeve), which are convenient and economical in construction.

Features of Weholite Structured Wall HDPE Pipe

1). High Ring Stiffness

2). High Brunt Intensity and low weight

3). Good creep deformation resistance.

4). Outer pressure resistance.

5). Erosion resistance ( such as acid, alkali and salt etc. )

6). Long life of approximately 50 years.

Applications of HDPE structured wall pipe:

- Storm Water Management./ Storm water Attenuation Application / Storm water pipelines.

- Sewerage Pipelines- Drainage Pipelines

- Culverts.

- Pipe rehabilitations.

- Landfill drainage/Leachate.

- Mine drainage.

- HDPE manholes. / Manhole Drops

- Floats

- Irrigation

Technical process:

Raw materials→Mixing→Vacuum feeding→Material drying→Single screw extrusion →Calibration→Spray cooling→Caterpillar traction→Single screw glue extrusion →Winding and forming→water cooling→cutter→pipe bracket→inspecting &packing.

The complete production line includes two parts:

1.The first part is PE Pipe extrusion line to extrude the PE/PP Square Shaped Pipe ( according to customers' requirements ).

Single Screw Extruder

Die Head (mold and mandrill)

Calibrator

Vacuum calibration&cooling Tank

Spray Cooling Tank

Haul-off

2. The second part is Spiral forming line to form and weld the big pipe.

Single Screw Extruder

Die Head

Spiral forming unit

Cutter

Bracket

High-efficiency single screw extruder

The extruder is equipped with the forced water-cooling feeding section and slotted barrel, which makes the power consumption of the main drive motor greatly reduced.

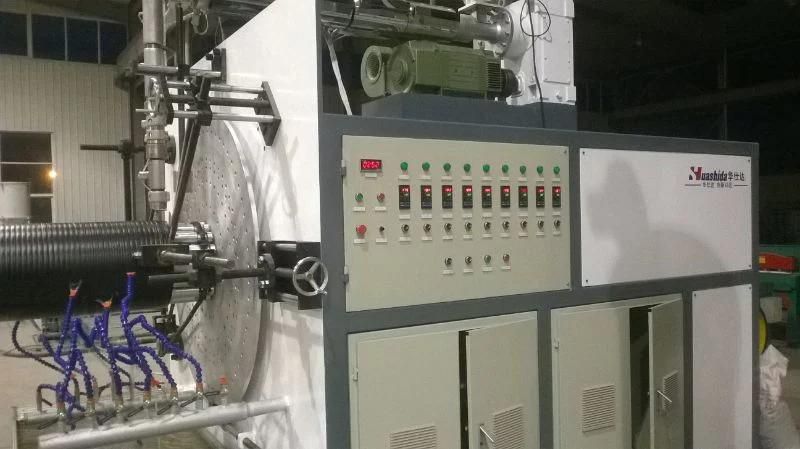

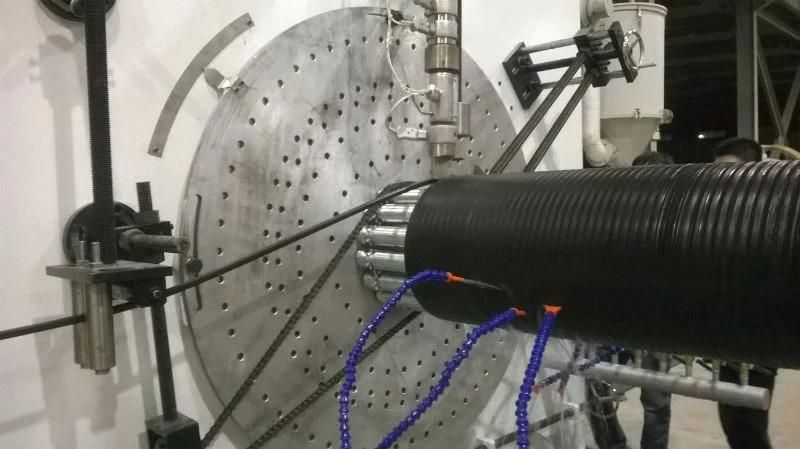

Spiral forming machine

Spiral spinning forming, exquisite structure, unique design, ensuring high product quality.

Control System

PLC computer control system with touch screen:

With super high speed and large storage capacity.

Multi points control: pipe extrusion, adhesive extrusion, winding and cutting process can be controlled synchronously or separately.

Data sheet

| Model | Pipe Diameter(mm) | Extruder | Speed of forming | Max. output | Installed Power | dimension |

| SKRG-1200 | Ø400-Ø1200 | SJ-65(50)X30 | 1-12m/h | 320kg/h | 230KW | 26X18X5 |

| SKRG-1600 | Ø800-Ø1600 | SJ-80(50)X30 | 1-6m/h | 500kg/h | 310KW | 27X18X5 |

| SKRG-2200 | Ø1000-Ø2200 | SJ-90(65)X30 | 0.5-5m/h | 650kg/h | 380KW | 28X19X5 |

| SKRG-3000 | Ø1600-Ø3000 | SJ-90(65)X30 | 0.3-3m/h | 800kg/h | 390KW | 48X26X6 |

Expert team supporting

Delivery

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23