CNC Laser Cutting Machine Equipment for Sale Steel Metal Sheet

Guangdong Seabond Import and Export Co., Ltd / 2022-06-23

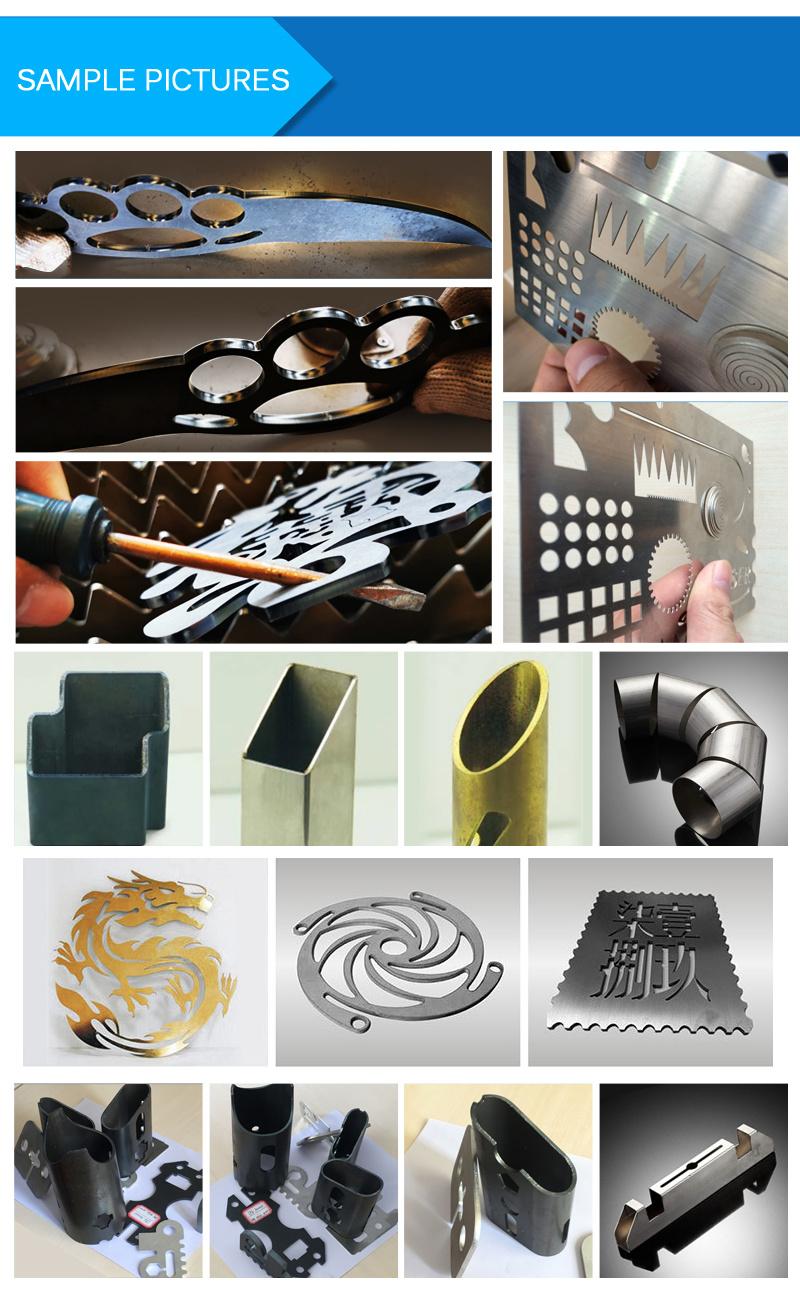

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Desktop

- Laser Classification:Solid Laser

=== Base Info ===

- Model NO.:CNC Laser Cutting

- Laser Technology:Laser Fusion Cutting

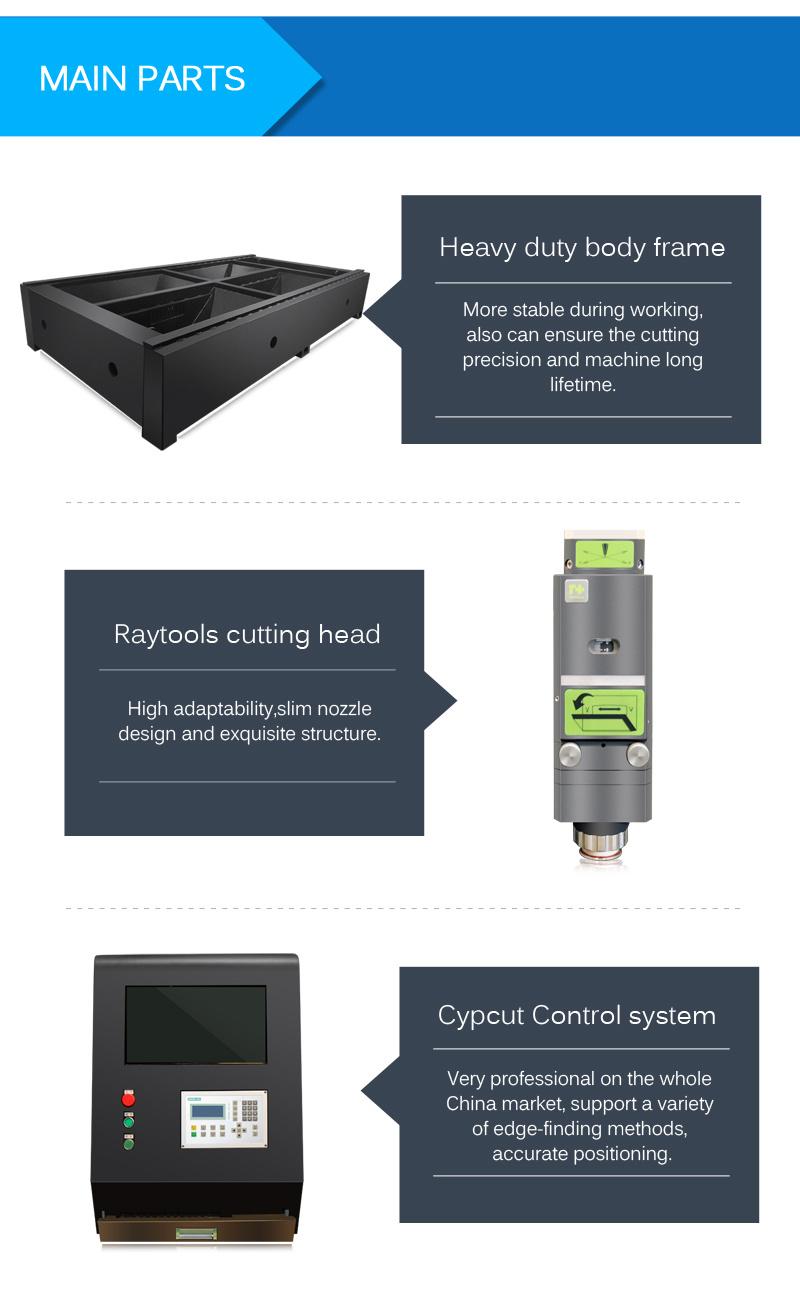

- Laser Cutting Head:Raytool

- Transmission:Double Driver Rack Gear

- Laser Power:1000W,1500W,2000W,3000W,4000W

- Warranty:2 Years

- Servo Motor and Driver:Japanese FUJI,Yaskawa Motor and Driver

- Guide Rail Brand:Taiwan Hiwin

- Laser Source Brand:Raycus,Ipg,Gw,Reci

- Rack Gear Brand:Taiwan Yyc

- Water Chiller:S&a Water Chiller Cwfl-1000

- Reducer:Original Italy Motovario Reducer

- Transport Package:20FT Container Loading, Shipping by Sea

- Specification:3000KGS

- Trademark:BaoKun

- Origin:Weifang, Shandong, China

- HS Code:8456110090

- Production Capacity:100set,Month

=== Description ===

The above parameters are for reference only, the actual process parameters will vary according to the configuration and actual use of each manufacturer.

| Model: | BKJ-F3015 |

| Working Area: | 3000*1500mm |

| X axis | Japan Fuji/Yaskawa Servo motors 850W |

| Y axis | Japan Fuji/Yaskawa Servo motors 850W |

| Z axis | Japan Fuji/Yaskawa Servo motors 400W |

| Positioning Accuracy: | 0.03mm |

| Repositioning Accuracy: | 0.02mm |

| Max Movement Speed: | 140m/min |

| Laser Power: | 1000W |

| Reducer | Original Italy Motovario Reducer |

| Guide Rails | Taiwan HIWIN (H Level) |

| Rack&Gear | Taiwan YYC level 6 |

| Contrlloer and Laser Head | Cypcut , Raytools |

| Water Chiller | S&A water chiller CWFL-1000 |

| Working Table: | Blade Working Table |

| Max Acceleration: | 1.4G |

Expert database allows for quick changes over between jobs, minimizing operator interactions, by automatically setting cutting parameters through the CNC

1. Jumping mode to enhance cutting effectiveness

2. Capacitive height control in quick response

3. Re-trace mode allowing for the cutting process control when cutting errors occur

4. Dynamic corning control allowing for automatic adjustment of power and gases for better cutting performance in corners and tight contours

5. Adjustable slope function to improve laser piercing quality

6. Cutting compensation function for line & circle cutting

7. Fly-piercing function with non-stop cutting which greatly improves the cutting efficiency for thin plates

8. Automatic plate edge detecting function for faster setup

1. Professional and free after-sales training

Our company has the professional after-sales technical team , providing customers prompt door-to-door or online technical guidance, which can ensure customers are skilled in the equipment application in a short time . At the same time , after-sales technical team would visit customers regularly ,asking customers the using of equipment and upgrade the software of equipment for customers.

2. After-sales outlets are all over the world

Our company has global customer service center , it has 16hours/day online customer service, which can solve all kinds of problems for domestic and foreign customers, our customer service will feedback problems to technical department and productive department,which would give you a satisfactory process of solving problem , ensuring constantly creation of money for you.

3. The feedback of customer satisfaction survey

Company 's after-sales service and technical department will visit customers regularly , inquiring your degree of satisfaction about the equipment and service , we would form proposal according to customer's feedback, the aim of it is finding continuous improvement.

4. The warranty commitment of equipment

The machine's warranty is on two years( not including optical devices and quick-wear parts), except that ,control software is free to upgrade . At the same time ,we guarantee that we will give you the most satisfactory answer for your question whether it is inside or outside of the machine..

Q: What's the function of fiber laser?

Fiber Laser is only used to cut metals like Stainless Steel, Carbon/Mild Steel, Galvanized Steel, etc. Non-metal is not ok.

Q: What's the max. cutting thickness?

Cutting thickness is related to laser power.

1000W: 5mm stainless steel, 12mm carbon steel

2000W: 10mm stainless steel, 18mm carbon steel

3000W: 10mm stainless steel, 20mm carbon steel, 10mm aluminum, 7mm brass, 4mm copper

4000W: 12mm stainless steel, 22mm carbon steel, 10mm aluminum, 10mm brass, 6mm copper

Note: only 1KW or above fiber laser could cut Aluminum, Copper, Brass and other high reflection sheet metal.

Q:Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23