Cheetos Making Machine/Kurkure Extruder/Snacks Food Machine

AIRMAX AL CO., LIMITED / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

=== Base Info ===

- Model NO.:KS-76 Single screw extruder

- Nachine Material:Stainless Steel

- Output:100-800kg,H

- Warranty:1 Year

- Total Weight:1000kg

- Main Motor:Simens(China)

- Type:Twin Screw Extruder

- Transport Package:Wooden Case

- Specification:30*3*4.5m

- Trademark:KS

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:100-200kg,H, 200-00kg,H, 500kg,H

=== Description ===

Basic Info.

Model NO. KS-76 Single screw extruder Nachine Material Stainless Steel Output 100-800kg/H Warranty 1 Year Total Weight 1000kg Main Motor Simens(China) Type Twin Screw Extruder Transport Package Wooden Case Specification 30*3*4.5m Trademark KS Origin Shandong China HS Code 8438800000 Production Capacity 100-200kg/H, 200-00kg/H, 500kg/HProduct Description

Cheetos making machine/kurkure extruder/snacks food machine Cheetos chips and kurkures making machine

Cheetos chips and kurkures making machine1.Product description :

1.Nik Naks/Cheetos/Kurkure/Corn curls are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits is moisturized in the flour mixer with water and fed to the Rotary Head Extruder. In the extruder, due to the two rotary plates made of yellow brass, the corn grits are squeezed and twisted to form curls shape. The curls pass through the die and gets cut by the cutting knifes into required lengths.

2. Raw materials : adopts corn grits as raw materials meanwhile mixing with water and oil

- Common and easy found material

Raw materials: adopts corn grits as raw materials meanwhile mixing with water and oil

- widely used to produce value-added food

Products: This line can be used to produce cheetos, kurkure, and nik naks

- Special Flow chart

Mixing system---Extrusion system----Baking system (Frying System) ---Flavoring system---Packing system

3. Capacity : 100--150kg/h

4. Flow chart :

Mixing system---Extrusion system----Baking system (Frying System) ---Flavoring system--

Packing system

6. Voltage : Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to

customers' Local voltage according to different countries

7. Machines Materials: All the machines are made by stainless steel

8.Technical Parameter

Model | Installed power | Real power | Output | Dimension |

KS-76 | 96KW | 62KW/H | 120-150KG/H | 17000*1100*2500mm |

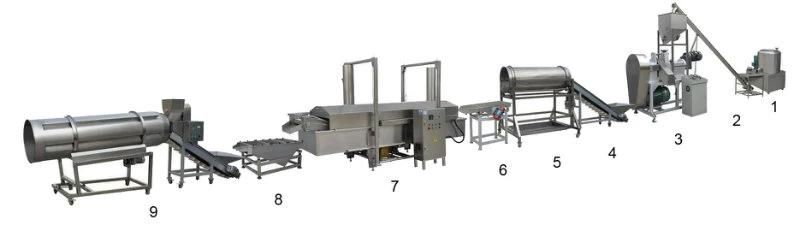

1. Flour Mixing 2. Screw Conveyor 3. Extruder 4. Hoister 5.Drum sieve

1. Flour Mixing 2. Screw Conveyor 3. Extruder 4. Hoister 5.Drum sieve6.Vibrative feeder 7. oven or fryer with De-oiling machine 8.Hoister

9.Flavor machine

1. Mixer : to mix various flour evenly

2.Screw conveyor: to convey the mixed flour to the rotary head extruder by uniform speed

3.Rotary head extruder: to extrude the raw material to raw cheetos /kurkure

4.Belt elevator: to convey the products to the next process.'

5.Separation and cooling machine: to cool the cheeto and sift the un-qualified cheeto /kurkure.

6.Drying baking machine: to dry extruded cheetos by removing the extra moisture under high temperature

7.Flavoring machine: to spray seasoning powder and oil onto the cheeto /kurkure to achieve delicious taste

3.The detail process:1. We can provide factory layout according to customer's factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country, and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the food. and help customer to produce good quality food according customer's detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

4.Our Goal

1)Our goal is to make sure you are a happy customer and pleasant business with us.

2)If you are not satisfied with your purchase in any way, Please give us the opportunity to resolve any problem. We understand the concerns and frustrations you might have, and will try our best to resolve the issues.

3)If you're not pleased with your purchase, we'll be happy to make an exchange or refund in delivery days.

4)For any exchange or refund, we need the product must be in its original condition, including the box, and all the accessories. buyers are responsible for the returning shipping cost.

5. Samples Pictures Made By Extruder1. Blower to ensure discharge products faster and unblocked,

2. Window on the Hopper to check the raw materials level and quantity easily,

3. Vibrant Motor on the Hopper ensure feed raw materials fast and successfully,

4. Inverters, Conductors and other electronic parts are from World-famous Brands, like FUJI, LG, DELTA.

5. Main Motors are from SIEMENS(CHINA), ensure strong and excellent performance.

6. Package and Shipping:

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

7. FAQ Service:

Q:How you provide service?

A: We have professional team work for after sale service. Support 24x7 customer service by email,video talking,mobile. If the electronic component is broken within the warranty time we will send the new part within 48 hours by express like TNT, DHL, FEDEX, etc to the buyer. And the shipping cost should be on YQLASER for the new part and the old part should be sent back on the cost of buyer.

Q:Are you factory or trading company?

A: We (Jinan Yidiao CNC Equipment Co.,Ltd)are factory with more than 10 years experience of laser machine production.

Q:Do I need any necessary things to make the machine work after I have it?

A: No,do not need any other parts to make the machine work. Youcan just connect the laser source, air exhaust fans, water pump/chiller, air compressor and turn on the machine.

Q: How to get suitable machine (size and power) for our products?

A: kindly let us know, what are your target materials to be processed?

How is dimension of material (length x width x thickness)?

Q:Does your machine run from a laptop or PC?

A:Both are ok. Operation system Windows98/2000/XP/win7, win8, Apple mac.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23