Low Fluid Resistance Sjsz-51 PVC Water Pipe Production Extrusion Equipment Manufacturer

Ningbo Conwhole Hardware Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ-51 Customized Customized Condition New After-sales Service Installing in Customer′s Factory Length(M) 20 Width(M) 2 Height(M) 3.5 Contactor Siemens Converter ABB Relay Omron Temperature Controller Delta Product PVC Pipe Extrusion Equipment Transport Package Wooden Packing Specification 50-110mm Trademark Trusty Origin Qingdao HS Code 84772090 Production Capacity 20 Sets/MonthProduct Description

Low Fluid Resistance Sjsz-51 PVC Water Pipe Production extrusion Equipment Manufacturer 1.Company Profile Qingdao Trusty Plastic Machinery Company develops new products constantly, the products sell well all over the country,so we won the trust of customers from all sides.The products are in the leading position.Our company always adhere to the "integrity-based, quality, innovation and development" theme of the purpose, adhere to quality commitment to the customers.

1.Company Profile Qingdao Trusty Plastic Machinery Company develops new products constantly, the products sell well all over the country,so we won the trust of customers from all sides.The products are in the leading position.Our company always adhere to the "integrity-based, quality, innovation and development" theme of the purpose, adhere to quality commitment to the customers. 2.Production Introduction

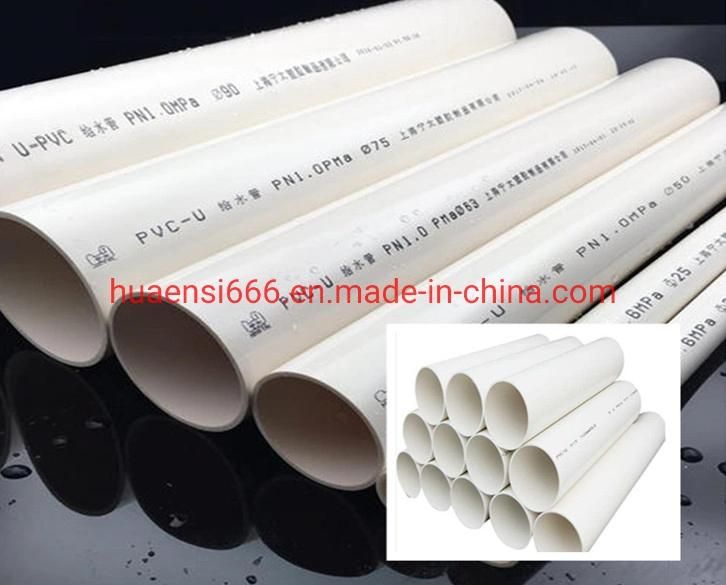

PVC water supply pipe extrusion equipment is mainly used for producing the pipes,which diameter from 50mm to 110mm.This production line consists of mixer,feeder,twin screw extruder,extruding mould,shaper , vacuum tank, haul-off with caterpillar,automatic cutter, roll over table,crusher and mill.

The high-quality haul off with caterpillar pulls the pipe at a constant speed.The automatic cutter saves the labour.This production line produces pipes with reliable and guaranteed quality .

3.Machine List for PVC pipe extrusion equipment

| Name | Quantity(set) |

| Mixer300/600 | 1 |

| Feeder | 1 |

| Twin screw extruder | 1 |

| Extruding mould | 1 |

| Shaper | 1 |

| Vacuum tank | 1 |

| Haul off with caterpillar | 1 |

| Automatic cutter | 1 |

| Roll over table | 1 |

| Crusher | 1 |

| Mill | 1 |

4.Technical Parameter

| Model | SJSZ-51 |

| Total installation power(kw) | 125 |

| Transformer (kw) | 100 |

| Actual electricity consumption(kw) | 50 |

| Capacity (kgh) | 120-140 |

| Line speed (mmin) | 2-5 |

| Pipe Diameter(mm) | 50-110 |

| Motor Power(kw) | 22 |

5.PVC pipe making Process

Mix the material→Feed→Extrude→Customize→Haul off→Cut→Stack the material →Crush→Mill

6.After sales service

(1)After the machines are finished, the seller will test all machines before shipment. If the buyer can not come to test the machine, we will test the machines and send the sample to buyer.

(2)After shipment, the seller will send one or two technicians to the buyer' s factory to help the buyer install the machine and train workers for buyer.

(3)We will supply all electricity drawing, machine installation drawing.

(4)When make shipment, we will put some spare electricity parts for free, like the barrel hearers, thermcouples, breakers, relays, and other items which is easier broken.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23