PVC/WPC Decoration Wall Board/Panel Ceiling Panel Extrusion Production Line

Ningbo Conwhole Hardware Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ-65/132 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Length(M) 18 Width(M) 2 Height(M) 3.5 Motor Bette Contactor Siemens Converter ABB Temperature Controller Omron Transport Package Wooden Packing Specification Customized Trademark Trusty Origin Qingdao HS Code 84772090 Production Capacity 20 Set/MonthProduct Description

PVC/WPC Decoration Wall Board/Panel Ceiling Panel ExtrusionProduction Line

1.Company ProfileQingdao Trusty Plastic Machinery Co., Ltd. is a professional plastic extrusion equipment manufacturer integrating design, research and development, production and sales.

The company's main products are rich, the production technology is mature, and the after-sales service is guaranteed. Products are sold at home and abroad, such as: Brazil, Chile, Mexico, the Philippines, Italy, Russia, Pakistan, Vietnam, India, Algeria, Egypt and other countries.

Our company is located in Qingdao, one of the plastic machinery bases in China, where the railway, sea transportation, aviation and other transportation systems are very complete. And it is one of the regions with rapid economic development in the coastal cities.The advantaged geographical conditions have provided great convenience for the development of the company's trade.

Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, PVC/WPC crust foam board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

2.Production Introduction

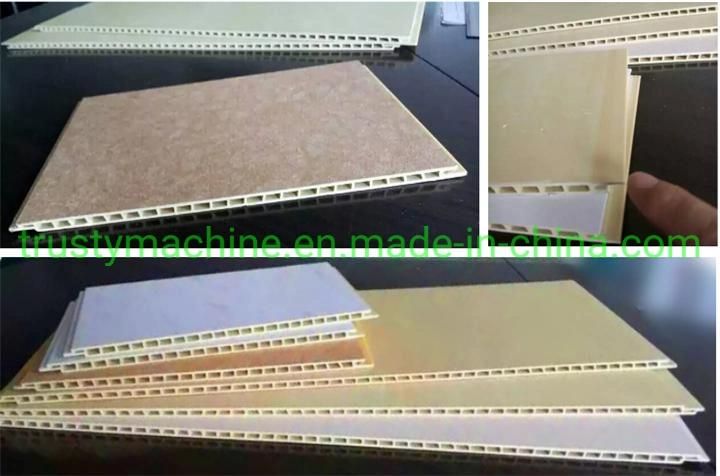

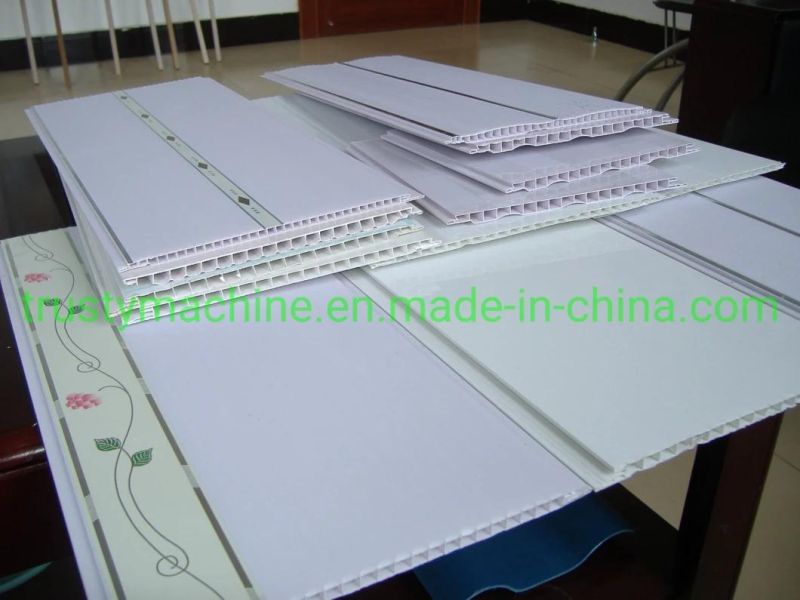

PVC /WPC wall panel line is mainly used to produce PVC / WPC wall panel and other PVC profile product like PVC window & door profile, PVC ceiling tile, PVC skirting etc. it is a kind of high efficiency equipment for plastic extrusion, it is mainly composed by force feeder, soft plasticization screw and barrel, high precision gearbox, exhaust system, it is features of even mixing, better plasticization,stable working, high capacity, and it is suitable for produce PVC products from mixed powder, within different mold and other auxiliary equipments, it can produce plastic pipe, profile, board, sheet, granules and so on.

3.Machine List

| Name | Quantity(set) |

| SHR-300/600 Hot & cold Mixer | 1 |

| screw loader &Feeder | 1 |

| Twin conical screw extruder | 1 |

| Extruding mould | 1 |

| Calibration table | 1 |

| Haul off | 1 |

| Cutter | 1 |

| Stacker | 1 |

| SWP-360 Crusher | 1 |

| SMP-500 Miller | 1 |

4.Technical Parameters

| Machine Model | Production Width (mm) | Production Thickness (mm) | Production Capacity (kg/h) | Total Power (kw/h) |

| SJSZ55/120 | 200-400mm | 8 | 120-150 | 70 |

| SJSZ65/132 | 600mm | 8 | 150-180 | 95 |

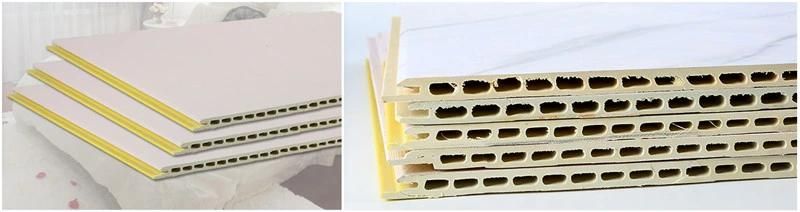

5.Advantage of PVC/WPC wall panel:

1.Easy installation, it can be installed directly onto concrete wall

2.No glue, the PVC/WPC wall panel are extruded directly, no glue used. Good for environment.

3.Multiple color choice. The PVC / WPC wall panel apply film lamination, so you can choose design and color which you like.

4. Easy to change. After use several years, if you want to redecorate the house, it is easy to take off from the wall and change to another design.

6.FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23