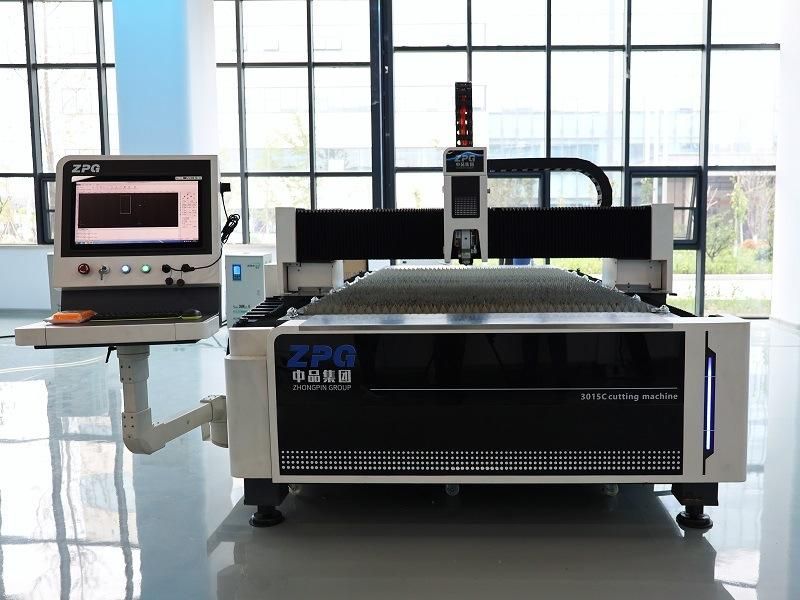

Zpg Double Drive Enclosed Type Exchange Table Fiber Laser Metal Cutting Machine Provide OEM ODM Italy/Brazil/Turkeyclosed Type CNC Fiber Laser Cutting Machine

Guangzhou Emei Packaging Products Co., Ltd. / 2022-06-23

- After-sales Service:on-Site Installation and Training

- Warranty:3 Years

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

=== Base Info ===

- Model NO.:ZPG-3015H

- Structure Type:Gantry Type

- Laser Classification:Fiber Laser

- Laser Technology:Fiber Laser

- Certification:CE

- Cutting Thickness:0-60mm

- Modelno.:3015-H

- Laser Head:Wsx Raytools

- Laser Source:Max Raycus Other

- Cutting Speed:155m,Min

- Transport Package:Wooden Packing

- Trademark:ZPG

- Origin:China

- HS Code:845611

- Production Capacity:1000sets,Year

=== Description ===

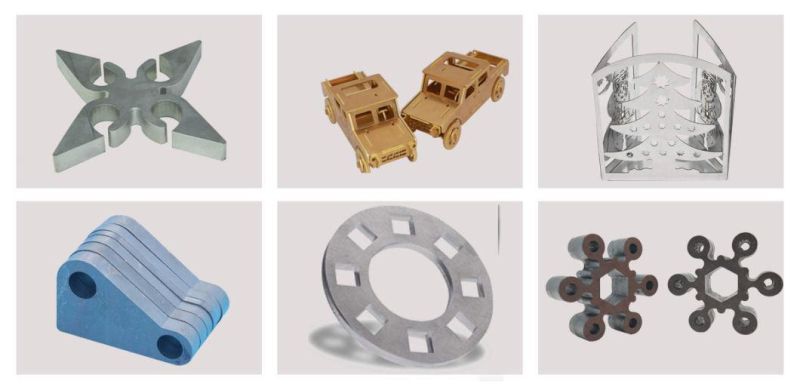

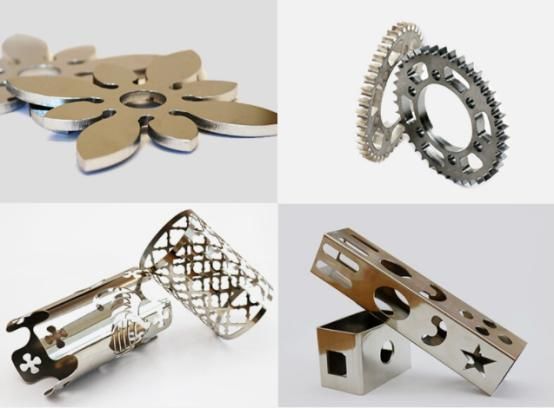

SpecificationWater Cooling Systemcutting samples

Company Profile

Company Profile

The headquarters of Zhongpin Group is located in Jinan, the spring city. It is a high-tech enterprise integrating R&D, manufacturing, sales and service of intelligent CNC laser equipment. It has two intelligent equipment brands, "PMSK" and "ZPG". Focusing on the fields of intelligent manufacturing of customized furniture and laser cutting of metal materials, respectively, we are committed to providing global customers with intelligent equipment and automation application solutions in two major areas. The group has a standardized intelligent equipment manufacturing base with a total area of more than 70,000 square meters, of which Qihe base covers an area of more than 60,000 square meters. It has built a high-level R&D center, a high-standard customer experience center, a business office building, and a staff restaurant. Standard machining center, the introduction of Japanese automatic welding robots, annealing heat treatment furnace, large shot blasting machine, CNC five-sided gantry milling, precision metal processing center and other CNC machining machines and high-precision testing equipment, to achieve 100% testing of key processes to ensure products Performance, quality and delivery time. The company has established a complete distribution and after-sales service network system at home and abroad, with more than 30 offices in the country, and exports to more than 80 countries and regions including Russia, North America, Turkey, Vietnam, and Malaysia. The group's laser cutting equipment products have achieved standardization and serialization, and serve global customers through domestic and overseas distribution service networks. In the future, Zhongpin Group will continue to devote itself to creating a domestic first-class intelligent CNC laser equipment machinery manufacturing base and R&D base to provide global customers with better products and services.

The headquarters of Zhongpin Group is located in Jinan, the spring city. It is a high-tech enterprise integrating R&D, manufacturing, sales and service of intelligent CNC laser equipment. It has two intelligent equipment brands, "PMSK" and "ZPG". Focusing on the fields of intelligent manufacturing of customized furniture and laser cutting of metal materials, respectively, we are committed to providing global customers with intelligent equipment and automation application solutions in two major areas. The group has a standardized intelligent equipment manufacturing base with a total area of more than 70,000 square meters, of which Qihe base covers an area of more than 60,000 square meters. It has built a high-level R&D center, a high-standard customer experience center, a business office building, and a staff restaurant. Standard machining center, the introduction of Japanese automatic welding robots, annealing heat treatment furnace, large shot blasting machine, CNC five-sided gantry milling, precision metal processing center and other CNC machining machines and high-precision testing equipment, to achieve 100% testing of key processes to ensure products Performance, quality and delivery time. The company has established a complete distribution and after-sales service network system at home and abroad, with more than 30 offices in the country, and exports to more than 80 countries and regions including Russia, North America, Turkey, Vietnam, and Malaysia. The group's laser cutting equipment products have achieved standardization and serialization, and serve global customers through domestic and overseas distribution service networks. In the future, Zhongpin Group will continue to devote itself to creating a domestic first-class intelligent CNC laser equipment machinery manufacturing base and R&D base to provide global customers with better products and services.

showroom

Factory

Factory Bed making process1.Plate welding

Bed making process1.Plate welding

2.First time heat treatment: 650ºC,16 hours

3.Powder coating, second time heat treatment, 200ºC,time depend on size

4.Gantry Milling

5.Machine bed production finishedAll the other process are done by ourselves.Spary painting and second time heat treatment done in our Sheet Metal Factory.Milling done in our Machining Workshop in Laser Manufacturing Base.So we can not only control the quality better, but also shorten the production time.certification

wooden Packing

wooden Packing  Packaging: Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt. 2)Shipping: We cooperate with the company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.

Packaging: Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt. 2)Shipping: We cooperate with the company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.

Q&A

Q1:Are you a factory or a trading company?

A1:We are a manufacture with rich experience, covering an area of 70,000 square meters.Q2:How do we guarantee quality?

A2:It is always a pre-production sample before mass production; Always perform a final inspection before shipment; Provide production, delivery, samples, etc. videos at all times.

Q3:Why should you buy from us instead of other suppliers?

A3:We are factory direct sales, with guaranteed quality and competitive prices.

Q4:Do you have after-sales support?

A4:Yes, we are happy to provide suggestions, and we also have skilled technicians.

Q5:What services can we provide?

A5:Accepted delivery terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, express, DAF, DES; Accepted payment types: T/T, L/C,credit card, Western Union, cash, escrow; Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23