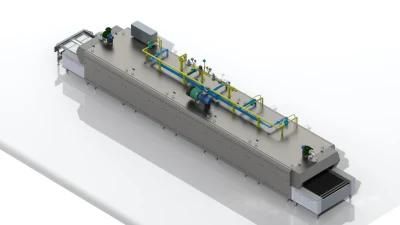

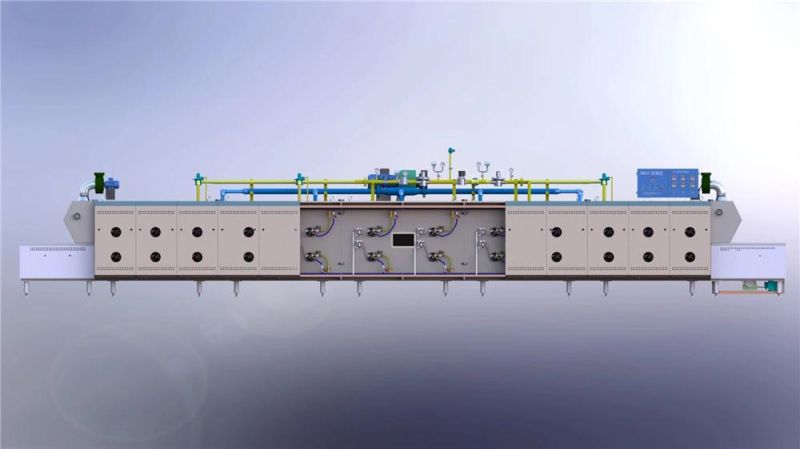

Stainless Continuous Gas Bakery Toast Baking Pizza Bread Food Tunnel Oven

Chongren Longtime International Co. / 2022-07-04

- After-sales Service:Field Maintenance and Repair Service

- Warranty:2 Years

- Usage:Cake, Pizza, Bread

- Power Source:Gas

- Timing Device:With Timing Device

- Type:Oven

=== Base Info ===

- Model NO.:ACN-190909001

- Voltage:380V

- Customized:Customized

- Electric Element:Schneider or Siemens or ABB

- Trays Insert Each Time:2-6 Trays

- Temperature Range:0-400ºC

- Function:for Bun Bread Production Line

- Components:10-Inch Touch Scree PLC, Imported Elements

- Steam System:Customized

- Transport Package:Wooden Case

- Specification:customized

- Trademark:AOCNO

- Origin:China

- HS Code:8417200000

- Production Capacity:20 Sets Per Year

=== Description ===

Basic Info.

Model NO. ACN-190909001 Voltage 380V Customized Customized Electric Element Schneider or Siemens or ABB Trays Insert Each Time 2-6 Trays Temperature Range 0-400ºC Function for Bun Bread Production Line Components 10-Inch Touch Scree PLC, Imported Elements Steam System Customized Transport Package Wooden Case Specification customized Trademark AOCNO Origin China HS Code 8417200000 Production Capacity 20 Sets Per YearProduct Description

An oven can be ordered and designed:1. The usage of the tunnel oven:

Suitable for loaf bread,buns, baguette, croissant,cakes,pita bread, arabic bread,bagel, tortilla, mamoul,panko etc.

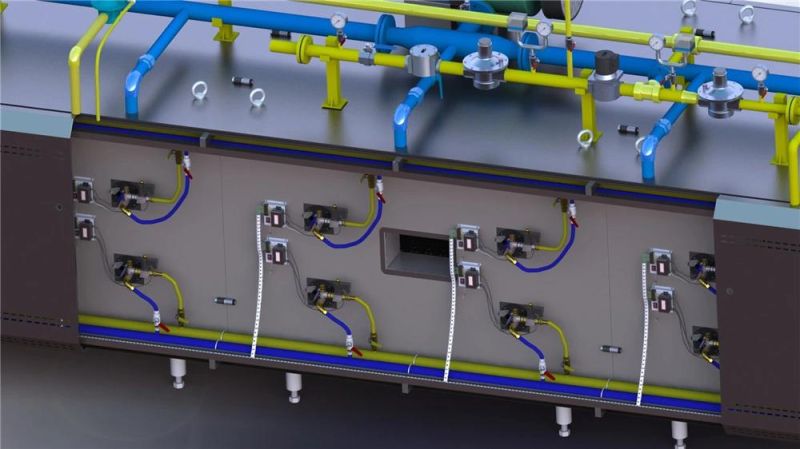

2. The advantage of proportion of zero-pressure gas-fired tunnel oven:

1) Insulation System:

A: Using rockwool insulation hybrid cotton,take access method for modular,more full of cotton insulation insulation properties, device power consumption to a minimum.

B: The inner wall of the oven used in all high reflection efficiency 1.5mm thick and 304 stainless steel bore, ensure the furnace during baking heat loss to a minimum.

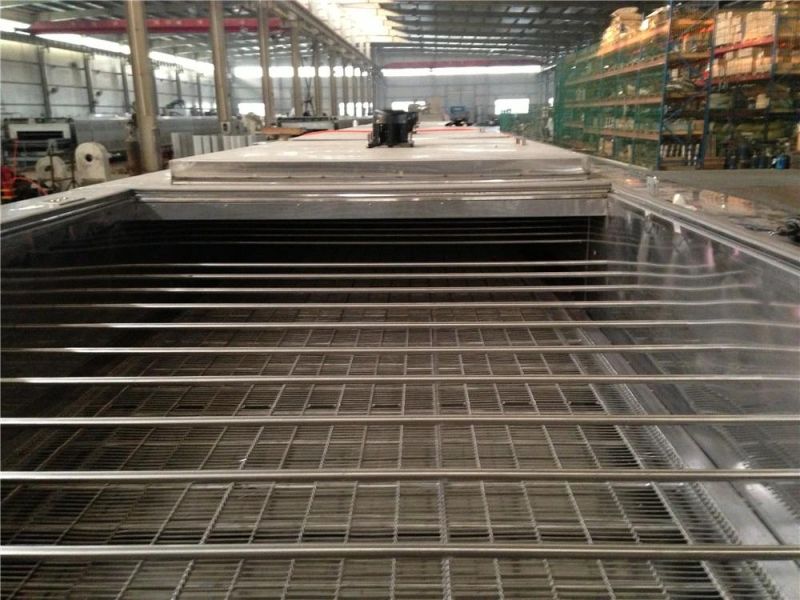

2) Drive section:

A: The transport conveyor is the chain plate form, it use Hangzhou Donghua chain belt(European technology, customized professional manufacturers),advantages of low noise, wear-resistant high temperature of 500 degrees, chain material collected 40Cr alloy materials, after tested, ultimate tensile load reaches 100KN longer life, better stability, give customers more peace of mind.

B: Chain plate with hot rolled plate bending from 3.0, surface appearance, high strength, flexural resistance, proper storage of heat, stable transfer amount fiery end, the furnace temperature equilibrium. Four bolt connection.

C: SEW reducer and matching motor powered, frequency stepless speed can be precisely controlled by the baking time, good acoustics, high stability.

D: Conveyor using 65Mn spring tension way, the flexibility to automatically adjust the tightness of the conveyor belt, the chain operated more in line with the requirements of mechanics, running more smoothly.

3) Exhaust systems:

A: According to the arrangement of the baking process food inflation hair, stereotypes dehydration, color three stages, exhaust pipe arranged in three stages.

B: Exhaust hood using natural air ejector exhaust hood design, ensure reasonable nature row tide, using exhaust hood exhaust pipe design, not directly connected to the furnace smoke pipe tobacco pipe, but connected to the exhaust hood, around of exhaust hood may enter natural air. Because the furnace temperature and altitude smoke tube forming hot outside temperature difference stress, continuous upward flow of hot air, exhaust hood external natural cold air into supplemented by the exhaust hood, so that the smoke pipe gas flow kinetic energy increases, exhaust more smoothly reasonable, the real heat loss without affecting the premise of rational water vapor discharge, excess water vapor in the furnace if it can not reasonably discharge but will reduce the oven temperature to produce steam emission beneficial during baking products, avoid dripping water vapor to the product, the impact of product shelf life.

Gas tunnel oven

| Dimension(mm) | L*2000*1500 |

| Specification | Gas |

| Voltage(v) | 380 |

| Fans Power(kw) | 2.2 |

| Baking Chamber Dimension(mm) | 1400*680 |

| Drive Power(kw) | 2.2 |

| Tray Size(cm) | 40*60 |

| Trays Insert Each Time | Two Trays |

| Dimension(mm) | L*2100*1500 |

| Energy | Electric |

| Electric Power(kw) | 12 |

| Voltage(v) | 380 |

| Transmission Power(kw) | 2.2 |

| Tray Size(cm) | 40*60 |

| Trays Insert Each Time | Two Trays |

Our company display:

Our company display:Hebei AONCO Baking Machinery Co.,Ltd founded in May 1984,covers 95 acres building area.We have modern plant,area up to 45,000 square meters and also an integrity building,5,000 square meters,which active for R&D center,products exhibition and marketing center and other facility.

Our main products is bread production line,like hamburger bun/hot dog production line,toast production line and Multifunctional bread line.The tunnel oven and spiral cooling tower conveyor is our hot sells.We can customized according your capacity and layout.

In 2018,we attend the IBA in Munich,Germany.

In 2019,we attend the IBIE in Las Vegas,USA

In 2019,we attend the GulfHost in Dubai.

We always moving forward and knows what you need.

AOCNO Baking Machinery are highly cost -effective,our products are not only popular in domestic markets,but also has gained good reputation from Latin America, Southeast Asia, Middle East Asia, Europe other in cover 50 countries.

If you are interested in our products or if you have special requirements, welcome to Contact Us With Any Enquiries!

Pls Feel free you may also come to visit and inspect our factory. So welcome here

Thank you!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23