Auto Potato Chips Production Line Potato Chips Processing Line

Taizhou Huangyan Jiaoxiang Plastic Mould Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Popcorn, Chips, Biscuit, Donut

- Customized:Customized

=== Base Info ===

- Model NO.:LY65 LY70 LY75

- Equipmenew Automatic Noodles Makint Name:Auto Potato Chips Production Line

- Frequency Converter:Delta Brand

- Machine Material:Stainless Steel

- Product Formula:Seller Provide Formula

- Warranty Period:12 Months

- Applicable Industry:Food Processing Machine

- After Sales Service:Seller Send Engineer for Installation and Training

- Spare Parts:Provide by Seller

- Delivery:Arrange by Seller

- Certificate:SGS,CE

- Automatic:Fully Automatic

- Key Words:Dog Food Extrusion Machine Plant

- Usage:Floating Fish Food Machine

- Voltage:Customer Settings

- Company Type:Real Factory

- Transport Package:Film&Wooden Box Packing

- Specification:2.5*1.2*1.5m

- Trademark:LOYAL

- Origin:Jinan, China

- HS Code:8438800000

- Production Capacity:5000 Sets,Year

=== Description ===

Basic Info.

Model NO. LY65 LY70 LY75 Equipmenew Automatic Noodles Makint Name Auto Potato Chips Production Line Frequency Converter Delta Brand Machine Material Stainless Steel Product Formula Seller Provide Formula Warranty Period 12 Months Applicable Industry Food Processing Machine After Sales Service Seller Send Engineer for Installation and Training Spare Parts Provide by Seller Delivery Arrange by Seller Certificate SGS,CE Automatic Fully Automatic Key Words Dog Food Extrusion Machine Plant Usage Floating Fish Food Machine Voltage Customer Settings Company Type Real Factory Transport Package Film&Wooden Box Packing Specification 2.5*1.2*1.5m Trademark LOYAL Origin Jinan, China HS Code 8438800000 Production Capacity 5000 Sets/YearProduct Description

AUTO POTATO CHIPS PRODUCTION LINE POTATO CHIPS PROCESSING LINE

PRODUCT DESCRIPTION

The potato chips is one kind of snack processed from fresh potato chips after washing, peeling, slicing, frying and flavoring. It remains the special the delicious flavor of roasted potato and has the characteristics of rich nutrition, delicious, convenient on the other and thus won the favor of the consumer.

HOW TO MAKE THE FRESH POTATO TO POTATO CHIPS AND FRENCH FRIES/FROZEN POTATO STICK.

Cleaning And Peeling Potatoes - Cutting- Rinsing - Blanching - Vibration Draining - Deep Frying - Deoiling (Air Drying and Lifting) - Spices Mixing - Weighing and Packing.

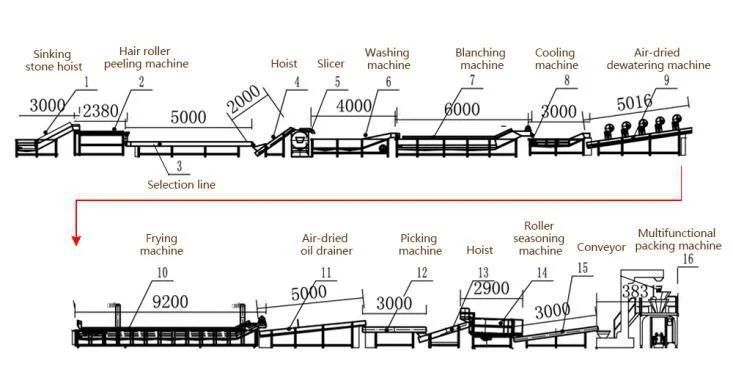

FLOW CHART OF AUTO POTATO CHIPS PRODUCTION LINE

FLOW CHART OF AUTO POTATO CHIPS PRODUCTION LINE

1. Peeling: firstly, the potatoes shall be washed and peeled by the potato washing and peeling machine.

2. Cutting:Cutting the fresh potato into strips or chips

3.Rinsing:put the potato strips into the ozone disinfection vegetables washing machine and rinse out the mucus on the surface.

4.Blanching: after rinsing, put the potato strips into the blanching machine for inactivating the oxidase in potato strips, preventing color deterioration and accelerating dehydration

5.Vibration draining: Shifting and removing the extra water in the chips or sticks.

6.Frying: after dehydration, the potato strips will be conveyed into the frying machine for deep frying by the lifting conveyor.

7.Deoiling (air drying and lifting): after deoiling processing by the air drying and lifting machine, the fried potato strips is sent to the spices mixing machine for flavoring.

8.Spraying Flavoring :the spice mixing machine is provided with the dip type seasoning drum which can automatically control the rotate speed and capacity of materials. The machine is equipped with automatic feeding device and the feeding capacity is adjustable. It can fully mix the potato strips with the spices.

9.Packing :after seasoning, the potato stripes are conveyed by lifting conveyor to the packing machine for vacuum packing or normal packing. The weighing device may be provided if it is necessary.

PRODUCTION CAPACITY OF AUTO POTATO CHIPS PRODUCTION LINE TO MAKE FRIED FRENCH FRIES

Semi automatic Line:20-30kg/h 50-60kg/h 100kg/h

Full Automatic Line:100kg/h 200kg/h 300kg/h 500kg/h

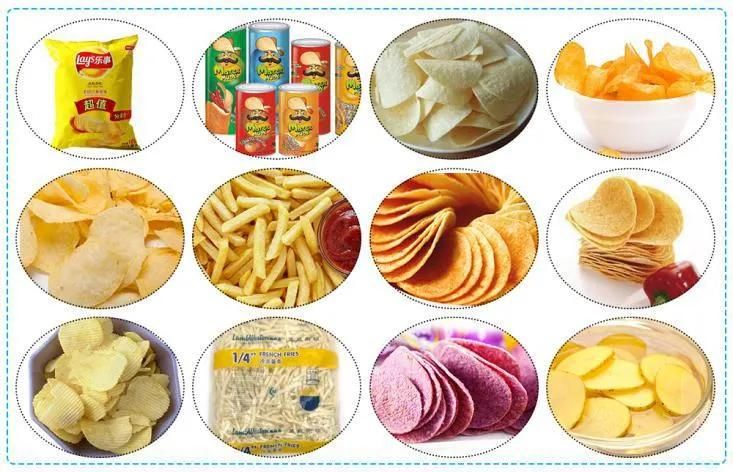

SAMPLES PICTURES OF AUTO POTATO CHIPS PRODUCTION LINE

PACKING AND SHIPPING OF AUTO POTATO CHIPS PRODUCTION LINE

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottom. With this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

OUR SERVICES

Our engineer would go to buyer's place to install the machine, when the equipment arrived at buyer's place.

1). Free consultation service before, during, and after sales;

2). Free project planning and design services;

3). Free debugging of equipment until everything is functional;

4). Free management of equipment long distance shipping;

5). Free training of equipment maintenance and operating personally;

6). Free new production techniques and formulas;

7). Provide 1 year complete warranty and life-time maintenance service;

CUSTOMERS FROM ALL OVER THE WORLD

Jinan Leader Machinery Co., ltd.-which is a professional food machine and packing machine manufacture with more than 15 years' experiences.We have exported to more than 80 countries.We devote to processing high-quality products with factory price to support your business.We are always your loyal partner and hope establish a good business relationship with you in the near future.Welcome to visit our factory.

COMPANY INTRODUCTION

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. - food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23