High Quality Acicular Crumbs Production Line Panko Breadcrumbs Process Line

ZheJiang Kincess Innovative Materials Co., Ltd. / 2022-07-05

- After-sales Service:Online Support

- Warranty:12 Months

- Certification:CE, SGS

- Power Source:Electric

- Process:Extrusion

- Automatic Grade:Automatic

=== Base Info ===

- Application:Bread Crumbs

- Customized:Customized

- Product Name:Bread Crumbs Production Line

- Type:Extruded Food Machinery

- Automatic:Fully

- Certificate:CE,SGS

- Extruder Type:Double-Screw Extruder

- Raw Material:Wheat Flour

- Material:Food Grade Stainless Steel

- Delivery Time:30 Days

- Service:After-Sale Service

- Transport Package:Wooden Case

- Specification:20000*1300*2200mm

- Trademark:Himax

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:15 PCS, Month

=== Description ===

Basic Info.

Application Bread Crumbs Customized Customized Product Name Bread Crumbs Production Line Type Extruded Food Machinery Automatic Fully Certificate CE/SGS Extruder Type Double-Screw Extruder Raw Material Wheat Flour Material Food Grade Stainless Steel Delivery Time 30 Days Service After-Sale Service Transport Package Wooden Case Specification 20000*1300*2200mm Trademark Himax Origin Shandong China HS Code 8438800000 Production Capacity 15 PCS/ MonthProduct Description

High quality Acicular Crumbs Production LinePANKO Breadcrumbs Process LineProduct description:

1).Bread crumbs is a widely used food additive for deep fried food, and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.The processing line replaces the traditional production technology.

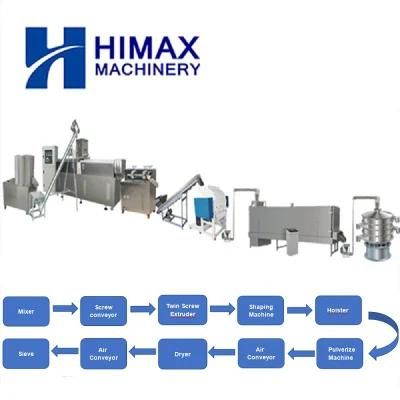

2).Flow chart: Mixer-Screw conveyor-Twin screw extruder-Cutter-Hoister-Humid crusher-Air conveyor-Multi-layer roasting oven-Air conveyor(or vacuum feeding machine)-Grading sifter.

3).Capacity: find below form.

4). Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries

5). Machines Materials: All the machines are made by food grade stainless steel.

Main Features for Bread Crumbs machine

1) Bread crumb machine Standard configurations:Mixer→ Screw conveyor→ Twin screw extruder→ Shaper→ Hoister→Miller→Sifter→ Air conveyor→Dryer→ Container→Vacuum feeder → Sifter

| Model | HM65 | HM70 | HM85 |

| Install power | 65kw | 110kw | 190kw |

| Consumption power | 42kw | 77kw | 133kw |

| Output | 120-150kg/h | 220-260kg/h | 500-600kg/h |

2) Bread crumb machine Various products:

Round ball, Circle ring, Bear, Star, Half moon, Curls, Flower, and Triangle, and so on.

Method to change the shape: We will design the specific shape which you want to produce accordingly.

Certificates:

Our Company:

Jinan Himax Machinery Co.,Ltd is a comprehensive manufacturing and trading company in China.Our company is a professional manufacturer of food process equipment.

Our main products line include food extrusion machine, soya meal/meat processing machines, industrial micro wave oven, packaging machines, rice cake machine etc... Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

All inquiries are welcome.

Our Service

Pre-Sales Service

1.Provide the free consultation of the equipment

2.Provide the standard device and the flow chart

3. According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

4.Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

5.Welcome to visit our factory or the domestic clients' factory.

6.Inspect the machine before leaving the factory.

After-Sales Service

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. We will provide 1-2 engineer to the client's factory for the installation and teach totally in 10 days. The client need provide room, food, round-trip transportation, visa and a nominal $50 daily subsidy per person.

Package and Delivery:

Contact Us:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23