Cassman 1000L Stainless Steel Beer Conical Fermentation Tank for Brasserie

Qingdao Kairui Packaging Co., Ltd. / 2022-07-04

- Processing Material:Stainess Steel 304

- Application:Beverage, Beer

- Customized:Customized

- Certification:CE, MET, CSA, UL, SA8000, ISO9001

- Power Source:Customized

- Automatic Grade:Customized

=== Base Info ===

- Model NO.:CM-1000L

- Product Name:Cassman 1000L Stainless Steel Beer Fermenter

- Key Words:Beer Fermenter

- Thickness of Tanks:3mm,2mm

- Material:SUS304,SUS316,Red Copper

- Function:Brewing Beer Brewing Equipment

- Polishing:0.4-0.6 Micron

- Accessories:Included

- Surface:Pickling Passivation

- Sample Valve:Yes

- Relief Valve:Yes

- CIP Ball:Yes

- Pressure Valve:Yes

- Pressure Gauge:Yes

- Conical Fermenter:Yes

- Transport Package:Fixed with Iron Shelf Packed in Plywood Wooden Box

- Specification:1000L

- Trademark:Cassman

- Origin:Jinan, Shandong, China

- HS Code:8438400000

- Production Capacity:50000 Set, Year

=== Description ===

Basic Info.

Model NO. CM-1000L Product Name Cassman 1000L Stainless Steel Beer Fermenter Key Words Beer Fermenter Thickness of Tanks 3mm/2mm Material SUS304/SUS316/Red Copper Function Brewing Beer Brewing Equipment Polishing 0.4-0.6 Micron Accessories Included Surface Pickling Passivation Sample Valve Yes Relief Valve Yes CIP Ball Yes Pressure Valve Yes Pressure Gauge Yes Conical Fermenter Yes Transport Package Fixed with Iron Shelf Packed in Plywood Wooden Box Specification 1000L Trademark Cassman Origin Jinan, Shandong, China HS Code 8438400000 Production Capacity 50000 Set/ YearProduct Description

Cassman 1000L Stainless Steel Beer Conical Fermentation Tank for BrasserieFermenter Detailed Specifications

Interior thickness=3mm Exterior thickness=2mm

100% TIG welding with pure argon gas shield

Interior tank: Pickling passivation+Exterior Oil brushed finish 2B

Insulation: Polyurethane, TH = 80mm

Domed top cover+ 60°cone bottom

Glycol jacket: dimpled plate on cone & side

Test pressure 3 bar, working pressure 1.5 bar

PT100 temperature sensor & digital temperature gauge

Complete butterfly valves, fittings and parts as below:

• 2pcs x Lifting ear

• 1pcs x Dry hopping

• 1pcs x PRV( Pressure release valve)

• 1pcs x Pressure gauge

• 1pcs x Spunding valve

• 1pcs x Sample valve

• 1pcs x Temperature gauge

• 1pcs x Carbonation stone

• 1pcs x Racking arm

• 1pcs x CIP spray device

• 1pcs x Drain outlet

• 2 pcs x Solenoid valve

• 4 Heavy duty legs with leveling pad

Part 1 Malt Miller System

Capacity: 100kg/h, 300kg/h, 500kg/h, 800kg/h, 1000kg/h.

Description: CE or UL listed Motor, Double roller, distance adjustable, stainelss steel 304 material.

Optional: Flexible Auger.

Part 2 Brew House System

-Two-Four vessles or combined system.

-Capacity 100L-5000L, 1bbl-40bbl.

- Steam heated, electrical heated or natural gas

-Mash tun with mixer, steam jacket, VFD motor, insulated 80mm. Stainelsss steel 304.

-Lauter tun with rake system, milled false bottom, sparging spray ring,VFD motor, insulated 80mm.

-Boiling kettle with steam jacket, inner heated option, insulated 80mm. Stainelsss steel 304.

-Whirlpool with Tangential whirlpool inlet. insulated 80mm. Stainelsss steel 304.

-Insulated HLT and CLT with the pipelines and pumps

-External grant, hops back, heat exchanger.Wort oxygenation system, working platform.

-All the necessary pipelines and pumps.

Part 3 Fermenter&BBT System

-Capacity: 100L-30000L, 1bbl-100bbl, +25% Head space

-Interior shell thickness 3-6mm, Exterior shell=2mm

-100% TIG welding with pure argon gas shield

-Interior finish: pickled and passivated, external polished, 80mm insulated

-Test pressure 3 bar, working pressure 1.5 bar

-Glycol zones (Both on side and concial/bottom)

-60°conical bottom for Fermener, Shadow less side man way

-Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

-Mechanical relief valve 3 bar on CIP arm with pressure gauge

-Adjustable tank leveling pads

Part 4 Cooling System

Description: Air type chiller + Ice water tank or Glycol tank

Capacity: 3HP, 5HP, 7HP, 10HP, 15HP, 20HP, 30HP+ 500L-20000L tank

Brand: Copeland, SANYO.

Part 5 Control System

-PID or PLC system

-SIEMENS program S7-200, Siemens touch screen.

-Penumatic valves for optional

Part7 Packge and Shipping

Part 8 Our Certification

Part 9 Company Profile

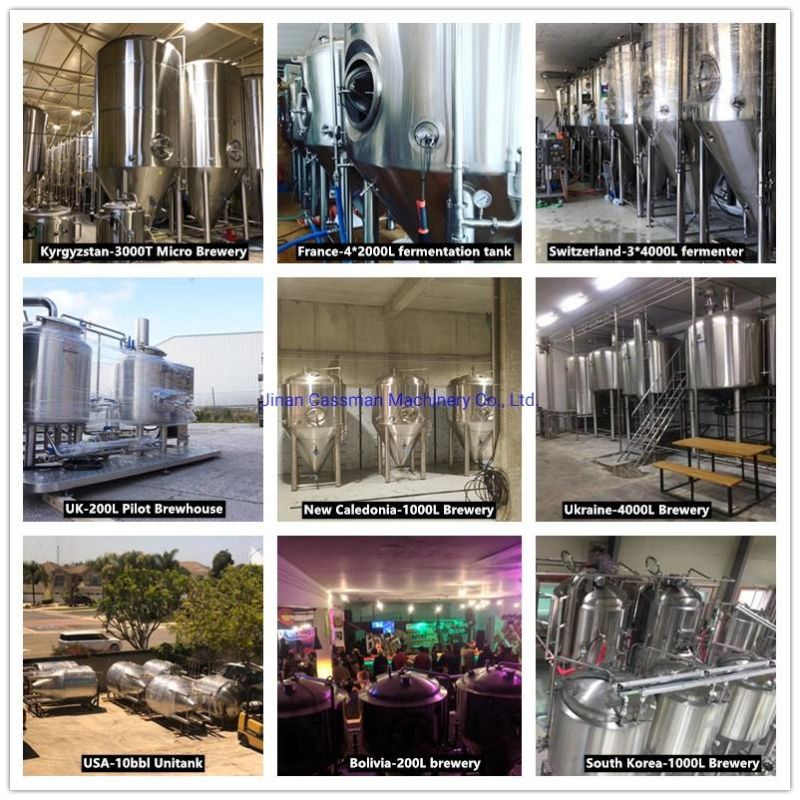

Cassman is the leading Microbrewery equipment supplier in China, our service include the brewery design, equipment manufacture, Installation at site and brewing technology transfer.

We provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system, cooling system, cleaning system, control system, package line.

Established in 2010, Cassman brewing equipment has been exported to more than 20 countries, which include USA, Canada, Australia, Japan, UK, France, Germany, Denmark etc.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23