Grain Silo Wheat Maize Silo Bin Galvanized Steel Silos 500tsilo to 3000t Silo

Cangnan Laijiu IMP & EXP Co., Ltd. / 2022-07-05

- Type:Grain Storage Silo

- Application:Flour, Steel Silo

- Voltage:380V

- Appearance:Vertical

- Press Materials:Corn

- Press Series:Super White Maize Flour

=== Base Info ===

- Model NO.:silo

- Condition:New

- Customized:Customized

- Capacity:500t to 3000t Silo

- Project 1:3000t Grain Stock Silo in Congo

- Project 2:3000t Grain Stock Silo in Zambia

- Project 3:2000t Grain Stock Silo in Kenya

- Project 4:1000t Grain Stock Silo in Angola

- Project 5:500t Grain Stock Silo in Tanzania

- Branch Office:Zambia, Uganda, Ethiopia

- Control System:Touch Screen Control, PLC

- Warranty Time:Two Year for Maize Flour Milling Machine

- Location:Hebei, China

- Spefication:as Required

- After Sales Service:Install Silo Overseas

- Transport Package:Standard Packing for Silo

- Specification:GB1355-88

- Trademark:hongdefa

- Origin:Hebei China

- HS Code:84378000

- Production Capacity:More Than 100 Sets,Year

=== Description ===

Basic Info.

Model NO. silo Condition New Customized Customized Capacity 500t to 3000t Silo Project 1 3000t Grain Stock Silo in Congo Project 2 3000t Grain Stock Silo in Zambia Project 3 2000t Grain Stock Silo in Kenya Project 4 1000t Grain Stock Silo in Angola Project 5 500t Grain Stock Silo in Tanzania Branch Office Zambia, Uganda, Ethiopia Control System Touch Screen Control, PLC Warranty Time Two Year for Maize Flour Milling Machine Location Hebei, China Spefication as Required After Sales Service Install Silo Overseas Transport Package Standard Packing for Silo Specification GB1355-88 Trademark hongdefa Origin Hebei China HS Code 84378000 Production Capacity More Than 100 Sets/YearProduct Description

Grain Silo Wheat Maize Silo Bin Galvanized Steel Silos 500Tsilo to 3000T silo

Grain/Wheat/Maize Silo for Storing Grain in Africa America

1. We are the professional factory for silo.

2. CE, ISO, BV, SGS certificate.

3. Our factory is in Shijiazhuang of Hebei province.

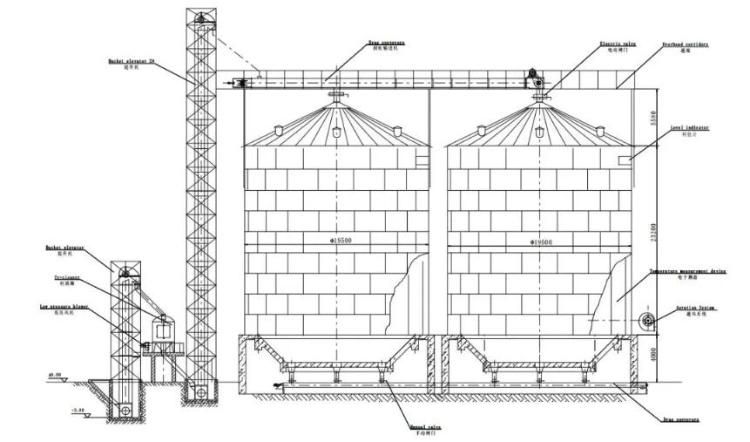

grain silo with capacity of 100-10000tons in such different discharge forms as flat bottom, cone bottom, fluidized discharging, multi-outlet discharging, and undertake turnkey project starting from process and civil work design, auto-control system as well as manufacture, installation, commissing of the associated equipment for lifting, cleaning, magnetic separating, metering, drying, fumigating, cold storing, ventilation, dust collecting, temperature and moisture measuring up to personal training and so on.

Hongdefa factory

Certificate

Parts of Grain Silo:

1. Pre-cleaning system.

2. Drying system.

3. Level monitor, temperature controller, ventilation system.

4. Silo body including silo roof, silo body, silo bottom and other quxiliary.

Advantages Grain Silo:

1.Good quality: grain silo material is double side galvanized steel, and all steel silo parts are manufactured in a factory, so the quality can be totally controlled.

2.Good air-tightness

3.All set auxiliar: temperature controller , DCS controller, level indicator, loading and discharging system.

4.Excellent stability

5.long-life time: 30 years working time.

6.Silo diameter: from 3m to 25m.

Grain Silo Features:

Automatic-flow unloading;

Hopper angles can be 45° and 60°;

Easily to be installed;

Less grain residues in steel insulated rice storage silo;

Hopper structure prevents loss of time and cost during the unloading period.

The silo can store raw grain. It can make the milling machine continuous production. The silo can promote efficiency and cost savings.

The construction technique of silo is the most advanced technology in the world. Its construction method is unique.

The patent technology of double profiling steel silos formerly belongs to West Germany. Double profiling is the technical feature.

| material of the silos | steel support inner, hot-galvanized sheet as the wall |

| bottom | steel cone bottom, plat cement bottom |

| capacity arrange | from 100tons to 10000tons |

Silo is made of hot galvanized steel, which makes it durable and weather resistant. It is specially used for bulk grain storage, such as wheat, maize, paddy,soybean, sunflower seeds, sorghum, barley,peanut and so on. The silo product has a designed lifetime of 30-50 years.

Double side galvanized grain storage silo are widely used in following processing plant:

The history of steel silo

People use steel silo for storage grain began from 1930, in the first stage, the steel silo is riveting type, with 6-10 mm steel plate riveted, it is very stong.

In the second stage, the steel silo is welded type. People use 4-10mm thickness's steel plate to make the silo. Welding silo has a good air tightness, strength, and can be high altitude. But it also has some disadvantages, such as surface anti-corrision ability is poor, expensive steel consumption, higher maintenance cost.

In the third stage, the steel silo is thin-wall type. In normally, there are two models: prefabricated corrugated steel silo and screw steel silo. In the middle of 19th century, in order to meet the needs of bulk grain transportation, the thin-wall steel silo is widely used. This silo has many features, such as light weight, easy installation, cheap price, high mechanization and automation, high efficiency, etc. Especially since 1970s, after production by standard materials, it has large-scale development. Especially Suiry Silo, we use galvanized inside vertical reinforce, it increases the anti-corrosion, rust resistance, longer life-span of the steel slio, its economical and pratical recognition in the industry.

The steel silo can be widely used in flour, feed, fats, alcohol, rice, corn, biomass power generation, ports, repository, and design institute.

Hongdefa clients

Client come visit Hongdefa factory.

My factory located in Shijiazhuang,Hebei,China. Next to capital Beijing China.

Welcome you come and visit my factory to check silo quality and factory ability.

I will pick you up at train station or airport.

Contact details:

Ms Grace

Shijiazhuang HONGDEFA machinery Co.ltd

No.388 jianhua north street,Shijiazhuang,China

Website:www.hongdefa.co.za

If you need high quality silo for wheat maize grain storage.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23