Vacuum Forming Plastic Machine Energy Saving with Redsant Heater Insulation System

Shenzhen Kaya Craft Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Origin China Production Capacity 10000 Sets/MonthProduct Description

RedsAnt insulation jackets provide a low-cost solution for reducing energy costs, and shortening start-up time between jobs by retaining heat inside barrels heater, extruders. This will lower the ambient temperature in your facility, and lower the overhead cost for equipment operations and air conditioning.Applications:

. Plastics Manufacturing Machinery

. Injection Molding Barrel Insulation

. plastic dryer

. Blow molding machine

. Extruders and extruder heads

. Heater of turbines

. Exhausted pipes

. Valve, Pumps, Flange

. high temperature equipment

. Plastic Vacuum Forming Machines

Insulation covers by RedsAnt can offer superb savings of up to 45% on barrel heating to save electricity and is manufactured with the support of over 10 years of experience, so quality is guaranteed.

Product features:

1. Heater Insulation covers will save the electric energy 25%-45% at the electric heating coil.

2. Improve the high precision injection quality by isolating the affects from environment temperature change and the wind influence. It has the function of temperature stabilization.

3. Sew by imported high temperature environmental friendly material, not the asbestos insulation materials.

4. Easy to disassembly and maintenance, reusable and long service life.

5. Products has passed the European Reach and RoHs environmental certification, products do not contain any toxic chemical composition of green environmental protection product.

6. Reduce the temperature of injection workshops. Improve the employees working environment.

7. Six months ROI (return-on-investment) with higher returns.

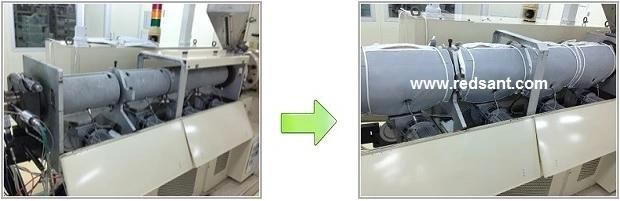

Installation photos:

More product information, please visit the company website in English version.

http://redsant.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23