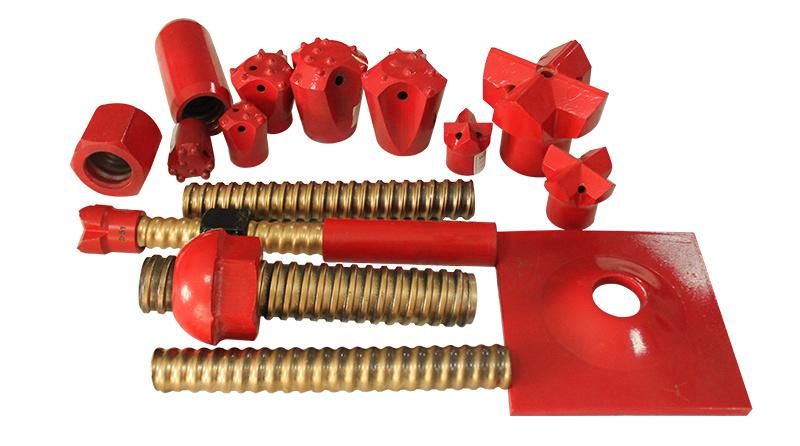

High-Performance7 Degree 28mm-95mm Tapered Ballistic Button Bit

Yuyao Ruimei Commodity Co., Ltd. / 2022-06-27

- Type:Core Drill

- Usage:Metal Drilling

- Certification:AISI

- Transport Package:Wooden Box

- Specification:42mm

- Trademark:YK

=== Base Info ===

- Model NO.:42mm

- Origin:Shandong Linqing

- HS Code:82071910

- Production Capacity:50000pieces,Month

=== Description ===

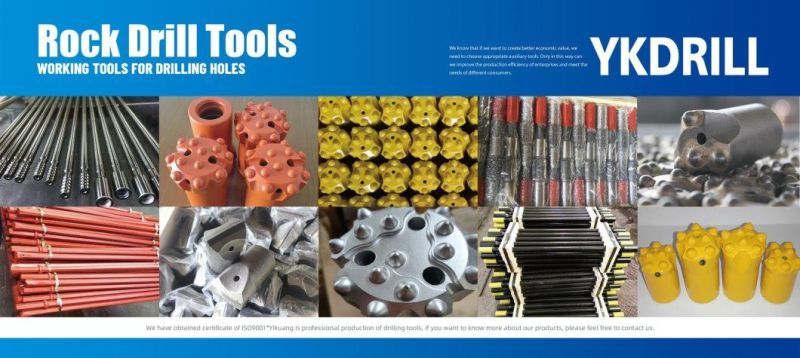

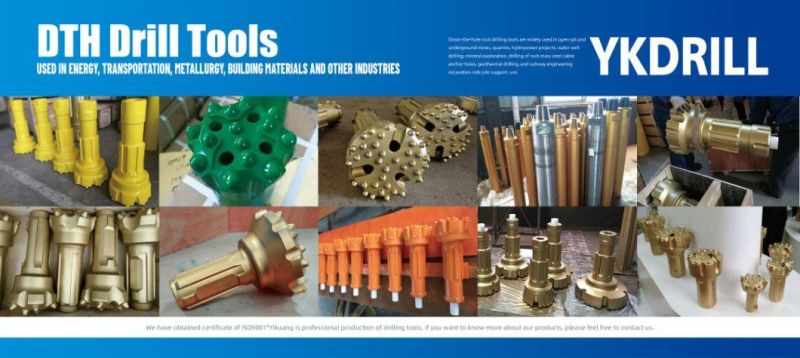

Product Description What is the advantage of our Button Bit ?

1. Material: 100% virgin raw material with submicron grain size;

2. Grade: Various grades for choice;

3. Advanced production equipments and testing equipments

4. Precision Ground and polished;

5. High wear resistance,high hardness and impact toughness;

6. Samples & small orders are acceptable.

The drill bit is the main tool of mining engineering impact drill, drilling and drilling machine parts is matched with the company, the product adopts the high quality alloy bit Zhuzhou hard alloy factory, the carcass quality 40Cr, 42CrMo and other materials Seiko production, to ensure the strength and toughness of drill bit. The company launched the conical connection hard alloy drill bit are straight and cross, three blade, ball gear and other four kinds of forms, many varieties and specifications.

Reasonable selection of drill bits and hard alloy

According to the drilling machine model, rock properties, hardness, toughness, pressure (pressure) choose a bit hard alloy bit type and, in general, fissures of rock should choose a bit; cross bit, three edge type bit is widely applicable to all kinds of rock, especially in hard and super hard abrasive high the fissures in the more obvious advantages; button bits for except the high rock abrasiveness of rock.

The usage method and matters needing attention of drill bit

1. Ensure a good match with the tapered drill rod (taper is consistent, the depth of the drill rod inserted into the drill hole must be more than 25mm, and the head of the drill rod should not be filled with the bottom of the drill hole, otherwise it is easy to cause the loss of the drill bit; Note: it is best to use the drill bit with the same tapered drill rod manufacturer to ensure that its taper is consistent and well coordinated.

2. the drilling machine should lower the air volume and reduce the damage to the bit caused by high stress on the cemented carbide sheet, and then use the normal air rate when the drill bit is fully drilled into the rock;

3. When the width of the platform is more than 3mm, it should be replaced or milled in time to avoid reducing the drilling speed, causing bit fragments, splits and reducing service life; When the taper of the bit appears, it is necessary to replace or repair the bit in time, otherwise, the bit will be worn seriously, the drilling speed will be reduced, and even the drill bit will be stuck. Use 46-60 silicon carbide grinding wheel when grinding, its line speed is not less than 18 m / s.

4. When using brazing bit, if it encounters foreign body such as steel bar, the drilling position should be adjusted to prevent the bit from being destroyed;

5. When rock drilling is easy to appear, one character bit should be replaced by cross bit or ball bit.

6. for the rock which causes serious wear of drill bit, slow drilling and serious debris, consideration should be given to replacing other alloy grade bit or using cross type bit and ball bit, and notify us in writing in time. In order to deal with in time.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23