30mx16m Big Fiber Laser CNC Cutting Machine Gantry, Iron Aluminium Carbon Steel Metal Alloy Cutter, Mini Machinery Performance Industry Equipment Big Cutting

Hangzhou Awesome Imp&Exp. Co., Ltd. / 2022-06-23

- After-sales Service:Offer

- Warranty:1 Year

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

=== Base Info ===

- Model NO.:ZLQ-BG

- Structure Type:Desktop

- Laser Classification:Fiber Laser

- Laser Technology:Laser Flame Cutting

- Cutting Application:Metal Plate Cutting

- Control System:Cypcut,Weihong

- Cutting Torch:Laser,Plasma,Flame

- Cutting Materials:CS, Ss, Alu, Copperm, Metal Alloy

- Cutting Thickness:0.1~200mm

- Machine Precision:0.02mm

- Cutting Area:3m*1.5m,6m*2.5m,Customize

- Laser Brand:Raycus,Max,Feibo

- Laser Power:500W~20000W

- Plasma(Option):Huarong,Huayuan,Hyperthem

- Plasma Current:65A,85A,120A,200A,300A,400A,500A

- Flame Gas(Option):Oxy& Acetylene,Propane

- Drive & Motor:Servo Driver+Motor

- Work Voltage:220V,380V,415V

- Certification:CE&ISO

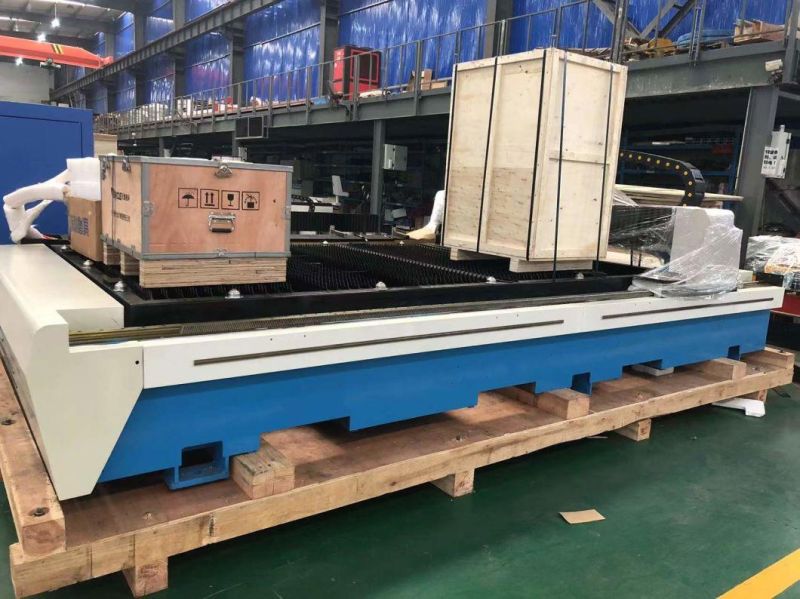

- Transport Package:Seaworthy Woodencase

- Specification:International standard

- Trademark:LANSUN

- Origin:China

- HS Code:84569010

- Production Capacity:800 Sets, Year

=== Description ===

Laser

(m/min)

Product Parameters

2. Basic equipment configuration

High anti-reaction ability thin plate cutting is efficient

Output fiber length can be customized

Air-cooled or water-cooled optional

Maintenance-free operation

Wide modulation frequency range

Control System

Can directly drive solenoid valve

Software resolution reaches the micron level

Rich laser cutting process parameters

Flexible layout and toolpath editing

Servo drive + motor

Smoother high-precision high-speed positioning

Speed response frequency

Deterioration diagnosis alarm model vibration compensation

Fully closed loop control

reducer

Automatically adjust parameters according to changes in room temperature

High temperature control accuracy

Dual temperature and dual control

Finished by high-precision large-scale gantry milling;

Ensure that the whole machine is strong and heavy without deformation

The overall accuracy error of the bed is within 0.02mm after finishing

The bed body is sprayed in strict accordance with the bottom layer anti-rust paint and top paint 4 layers

High-precision linear square guide rails are used both longitudinally and laterally;

Electric ratio

control unit

Ensure accurate gas pressure for thicker plate cutting is to ensure the cutting effect

Has extremely high sensitivity and durability

Cutting Samples

Our cutting system has a lot of cutting drawings,not only linearly cutting you also can cut the plate into different shaps easily by choosing and combining drawing from the system libarary.Packing&Delivery

Our cutting system has a lot of cutting drawings,not only linearly cutting you also can cut the plate into different shaps easily by choosing and combining drawing from the system libarary.Packing&Delivery Machines will be packed in seaworthy wooden cases strengthed by metal straps.We can ship to your carrier in China or deliver to your oversea destination.Why Choose Us Wuhan Lansun was established by leading experts and Engineering faculty from the China University of Geosciences,and has been specializing in design and manufactur of CNC cutting & welding machines for over 30 years.

Machines will be packed in seaworthy wooden cases strengthed by metal straps.We can ship to your carrier in China or deliver to your oversea destination.Why Choose Us Wuhan Lansun was established by leading experts and Engineering faculty from the China University of Geosciences,and has been specializing in design and manufactur of CNC cutting & welding machines for over 30 years.Our headquarter is located in the Wuhan East Lake High-Tech Development Zone.Lansun covers an area of 42 acres, and has 27000 square meters of facilities.We can manufacture 20pcs of machines per day. Our sales and service networks are throughout China and oversea.

Lansun has been designated as the base of teaching & research for the School of Mechanical Engineering and Electronic lnformation,China University of Geosciences. Our highly experienced R&D team keeps Lansun leading on the latest CNC cutting&welding technology,and continually launching leading machines into market.

Besides ISO,CE certification,our company also obtains a lot of inventation patents and software copyrights on CNC mechanism and controlling system.

As we are a factory,and our boss is professor from China University of Geology,we can control the R&D cost,manufacturing cost at a very low level and always can provide our customers with competitive prices.Factory can provide with instant and longterm after sale services.

As we are a factory,and our boss is professor from China University of Geology,we can control the R&D cost,manufacturing cost at a very low level and always can provide our customers with competitive prices.Factory can provide with instant and longterm after sale services.FAQ1. Are you a factory or trading company?

We are a factory,we engage in CNC cutting/welding machine designing and manufacturing for nearly 30 years.

2. Where is your factory located? How can I visit there?

Our factory is located in Wuhan, Hubei,the centre of China,the traffic is very convenient,we can pick you up at airport or train

station.

3. What's the quality of your machines?

Our factory has been certified by ISO,CE.Products are designed by ourselves,moreover most of the components are manufuctured by ourselves as well,so we can make our machines of hight quality while at relatively lower prices.

4. What shall we do if don't know how to operate your machine?

We have detail installing and operating instructions attached, also comes with video.Our after sale service hot line will be

available for 24H everyday.

5. What other things are also needed after we buying your machines?

(1) You need to prepare for oxygen and fuel gas if you want to cut by flame

(2) You need to prepare plasma power and air compressor if you want to cut by plasma.We also can procure these periphery devices for you,but you need to additionally pay for them.

6. What are your payment terms?

We support T/T, L/C, Western Union and so on. Other ways may also be acceptable after we both sides appropriately discussed and agreed.

7. What if we have any problem with the machine?

We will get back to you with solutions with maxmum of 12 hours after receiving your description of what the problem is.During the warranty period(generally 12 months), in case faulty material found at our discretion we will be responsible to repair or change.This clause does not provide coverage for lost or destroyed materials.8.What are the advantages of this model machine?

(1)Dual drives gantry design,makes cutting head moving more stably,ensures higher cutting precision.

(2)Equip with plasma torch and flame torch,can cut different thickness and different kinds of metals,eg.,can cut carbon steel up to 200mm.If customer would like, we also can additionally equip it with laser cutting torch.

(3)Automatic ignition when cutting by flame.

(4)The cutting size can be customized according to customers' requirements.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23