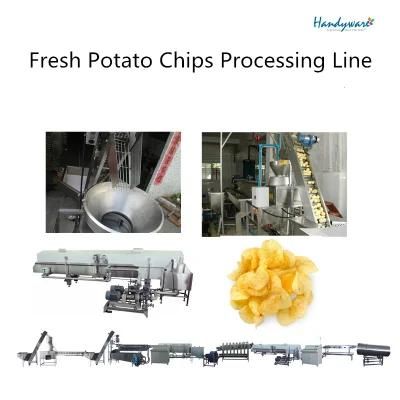

Easy Operation Fresh Potato Chip Processing Line

Cixi Xinhua Packing Co., Ltd. / 2022-07-04

- Certification:ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips

- Customized:Customized

=== Base Info ===

- Model NO.:FPCPL

- Power:45kw

- Electricity Requirement:380V,220V 50Hz,60Hz 3phase

- Compressed Air Supply:0.6-0.8MPa

- Weight:20t

- Material:Stainless Steel 304#

- Operating Mode:Automatic

- Transport Package:Wooden Box

- Specification:40m * 5m * 4.3m

- Trademark:Handyware

- Origin:Foshan

- HS Code:8438800000

- Production Capacity:200~500 Kg,Hour

=== Description ===

Fresh Potato Chips

Our strength:

>Top quality

304 stainless steel

Heat exchanger with certification

Burner from top european brand

>Experience in delivery fresh potato chip line

Jordan

Lebanon

Malaysia

>Experience in delivering fryer system

More than 40 sets to various countries

>Competitive pricing

In China, similar quality/load product sell at 1.5 times or more

In Europe/US, similar product sell at 2~3 times or more

>Excellent end product

Precise control of temperature and oil flow result in superior potato chips with uniform color and consistent finished moisture content

>Oil cost saving

No oil discharge required if run continuously

>Top quality

Manufactured using high quality stainless steel(304)

>Productivity

Labour: 8-9 pax

Low oil wastage

>Prevent over-cooking

Non-direct heating reduces oil rancidity

Heat exchanger used to maintain desired cooking oil temperature

>Easy to control

Central control panel to manage process parameters

>Cleaner oil

a) Low oil volume and rapid oil turnover assure fresh product with a long shelf life.

Optimal oil level is automatically maintained

b) Circulating oil keeps fines in suspension for efficient removal. Every minute, 100% of the system oil volume passes through a filter to remove product particles for the highest oil and product quality

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23