Auto Double Pipe Belling Machine (SGK160)

Poyang Tianli Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SGK160 PLC Siemens Electric Components Simens, Shneider, Omron Control PLC Automatic Transport Package Seaworthy Export Packing Specification SGS Trademark YS Origin Jiangsu, China HS Code 8477800 Production Capacity 50sets/YearProduct Description

SGK160 Full Automatic Double Pipe Belling Machine1. It is full automatic

2. With PLC control system

3. Single heating oven

4. Pipe size:90-250mm

New type full automatic double pipe belling machine with high speed and low consumption

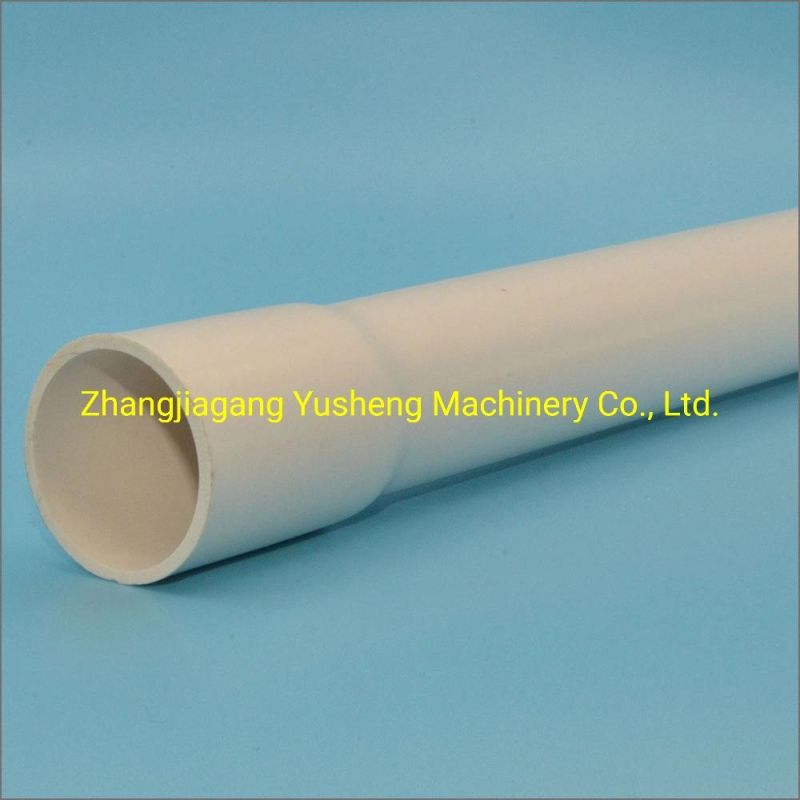

The plastic pipe belling machine is widely use to plastic pipe with different diameters and different materials. Its belling type have straight type and R type.

Features of automatic PVC pipe belling machine

1. Collocated with material-receiving pulling device as well as related process interfaces That are matched with the pipe extrusion line.

2. The machine can work together with the pipe extrusion line, or work alone.

3. Horizontally moves pipes, stable and accurate actions, and does not easily to Damage pipes.

4. Adopts infrared ray heating way and each heating furnace is located within the central Heating furnace core.

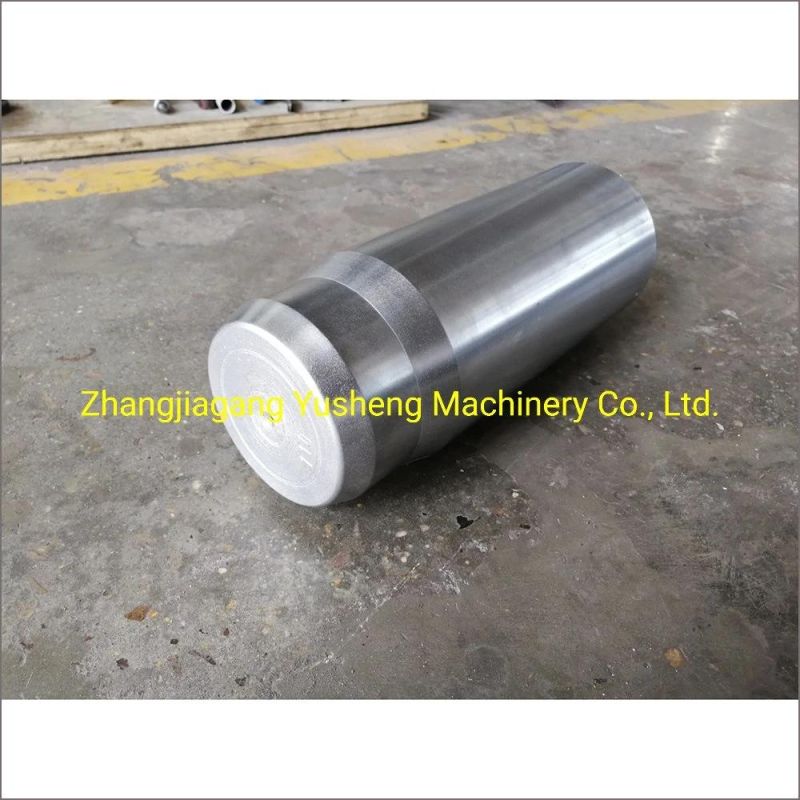

5. Adopts expansion tube head shaping method, with accurate dimension of nozzle.

6. Has conversion switches of expansion solvent plug (direct type) and expansion Flexibility sealing washer type plug (R type) in control panel, so it is very convenient To choose the way of tube expansion, with strong craft adaptability.

7. Main electric control components adopt imported famous brand, with stable and reliable System performance

| Pipe range(OD) | Φ50-160mm |

| Pipe length | 3-6m |

| Socket type | R type(rubber ring) or U type(solvent) |

| Socket method | R type: die tool expand with vacuum calibration U type: die tool insert with vacuum calibration |

| Cooling method | Water cooling (can make air cooling according to request) |

| Require cooling water pressure | 0.2~0.3Mpa |

| Quantity of heating oven | 2 |

| Heating method | Electric heating, by stainless steel heating rods |

| Heating power | 19.5kw |

| Total Power | 25kw |

| highest temperature in heater | 280ºC |

| Air pressure | 0.4~0.6Mpa |

| Center height | 1000mm±50mm (or according to extruder) |

| Machine set weight | About 1.8T |

| Require oil label | 46# wear resistance hydraulic oil |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23