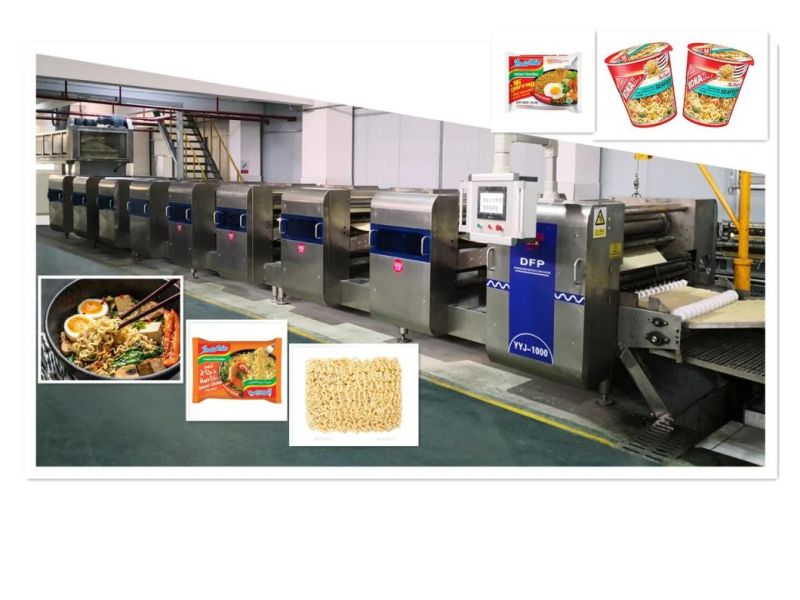

High Quality Instant Noodle Making Machinery Line Equipment

Ningbo Fantasy Packaging Co., Ltd. / 2022-07-05

- After-sales Service:10 Year

- Warranty:1 Year

- Processing Material:Wheat Flour Material

- Application:Instant Noodle

- Customized:Customized

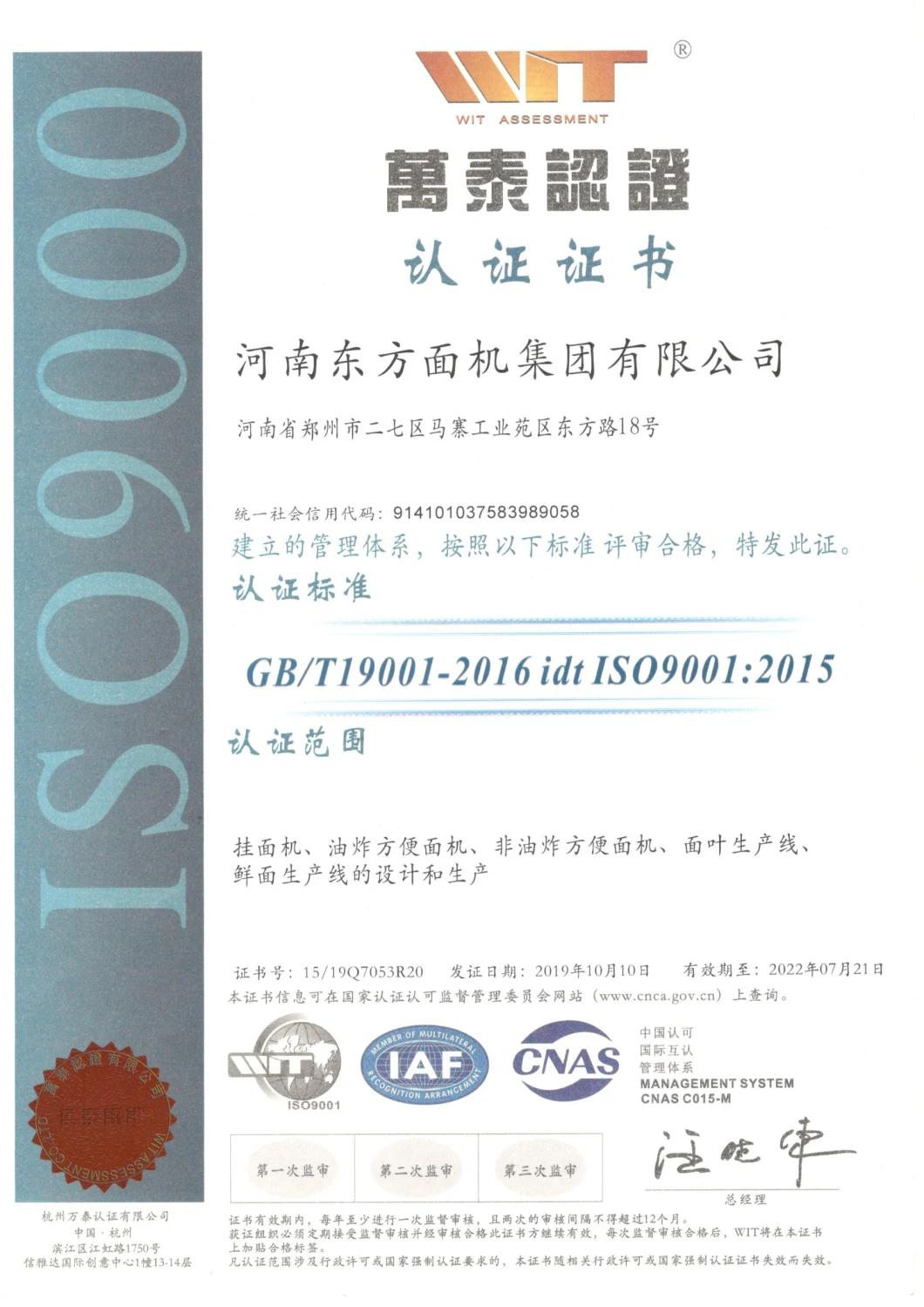

- Certification:CE, ISO9001

=== Base Info ===

- Model NO.:300-1000

- Power Source:Electric

- Automatic Grade:Automatic

- Product:Instant Noodle

- Material:Stainless Steel 304

- Raw Materal:Wheat Flour

- Product Shape:Round and Square

- Energy:Electric , Steam

- Processing Type:Frying

- Frequency Converter:Schnrider

- Product Formula:Seller Provide Formula

- Certificate:CE, ISO9001

- Voltage:Customer Settings

- Machine Material:Stainless Steel

- Transport Package:Container

- Specification:70m*7m*4.5m

- Trademark:dongfang

- Origin:China Zhengzhou

- HS Code:84381000

- Production Capacity:80000-160000PCS,8h

=== Description ===

PRODUCTS DETAILS

Dual-axis mixer

Dual-axis mixerThe dual-axis mixer is the traditional standard configuration and a key link of the fried instant noodle production line. The mixing ratio of materials is calculated accurately and the mixing is uniform. The new type of mixer has improved the water inlet form, shaft end sealing form, and shaft blade connection

The 1000 New Type Roller Machine

The 1000 New Type Roller MachineThe 1000 new type Roller machine adopts a brand-new appearance design, which is beautiful and novel, giving people a completely new feeling. Adopting four-axis feeding, smooth feeding, ensuring the integrity of the noodle sheet, and excellent sheet forming effect; especially the effective combination of photoelectric tracking and automatic sheet feeding, which greatly reduces labor intensity

Multi-layer Steamer

Multi-layer SteamerWater-sealed multi-layer noodle steamer is a new product developed by our company. It has a smooth appearance and is water-tight and air-tight, which solves the problem that the traditional multi-layer steamer must be sealed with rubber strips

cutter and divider

cutter and divider The noodle cakes will be sent to the inlet of fryer by silica gel tray after cutting and folding, through sliding plate into stainless steel noodle boxes. We add the interval water spraying structure to ensure the noodle cakes into boxes smoothly. The improved folding device has advantages of low noise and flexible. It can still work properly when the speed of cutting achieving 500 pieces/min Fryer

The fryer is the most critical equipment for producing instant noodles. The shape of the fryer is streamlined; the outer return of the noodle box reduces the height of the oil surface lengthens the oil drain section, adds strong oil blowers, and reduces the noodles oil content. 2-3% lower than similar products

Distributing conveyor

Distributing conveyorAfter cooling, the noodle cakes slides down to conveyor belt by T-shaped plate, then distributs into several separate lines into the packaging machine.

Finished Products Pictures

Cooperative enterprise

CE certification

OUR COMPANY

HeNan DongFang Noodle Machine Group Co., Ltd. is located in

Zhengzhou City, Henan Province, China, built in 1975, it's been more than 46 years,we are professional in the production line of the stick noodle and instant noodle, it is a large-scale noodle equipment manufacturer in China. There are 600 employees. And there are 40 patented technologies.

The main export countries include Indonesia, Bangladesh, Nigeria, Russia, Kazakhstan, India, Ecuador, the United States, Canada, Iran, South Korea, Vietnam, Turkey and more than 30 other countries and regions

OUR MAIN PRODUCTS:

1. Stick noodle production line

2. Square and round shape fried instant noodle production line

3. Non-Fried (dried) Instant noodle production line

4. Chowmen noodle production line

5. Fresh noodle production lineH

FAQ:

FAQ:1. Q: Are you manufacturers?

A: We are manufacturer of noodle machine with 40 years experiences, and more than 40 engineers, who can design the machine according to your special request.

2. Q: What is your noodle machine for?

A: Our noodle machine can produce many kinds of noodles, such as stick noodles, fresh noodles, instant noodles, fried instant noodles, non fried instant noodles, chowmein noodles, noodle leaves, extruding noodles, etc.

3. Q: How many countries have you exported to?

A: we have exported to more than 40 countries, such as Canada, Turkey, Malaysia, Nigeria, Bangladesh, Indonesia, India, etc.

4. Q: What is your delivery time?

A: 40-50days. For special request, we can deliver the machine within 30 days.

5. Q: What about aftersales service?

A: We have 30 after-sales service staff with overseas service experience, will to assemble the machine and train the customer's workers when machine arrives.

After sales service commitment

In order to provide better service for customers, to make customers feel more at easy after cooperation with our company.

Our company promise as follows:

1. Three guarantees should be implemented within one year from the date of completion and commissioning of the equipment.

During the warranty period, the company is responsible for repair and replacement of spare parts free of charge in case of failure due to internal quality problems of the equipment (excluding human factors).

2. After the equipment is delivered for use, the supplier should be provided with free technical guidance and training by electrical personnel and mechanical operators in the demander, including can learn after teaching and accommodation.

3. When the demander's equipment is in normal continuous production, the supplier shall send technicians to make a return visit by telephone or email once every six months, and assist the demander in equipment maintenance if there is any problem.

4. After the warranty period. The price of the equipment parts required by the demander (refer to the self-made parts of the supplier) can be reduced by 10% for timely supply.

5. The above services shall be provided until the demander stops using the equipment. During the use of the equipment, if the supplier has new technical projects launched, it can give priority to the technical transformation of the equipment for the demander, and only charge the cost.

Thank you for your review!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23