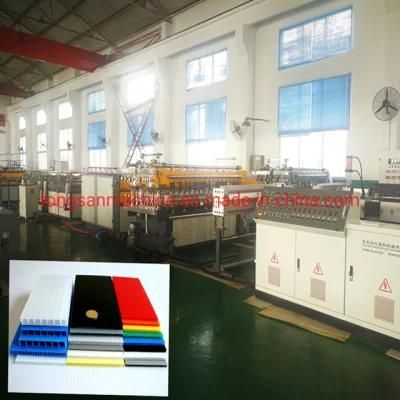

1220mm PP Hollow Corrugated Sheet Co-Extrusion Machine Sj100/36 +Sj65/36

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

1,Extruder for 1220mm PP hollow corrugated sheet co-extrusion machine SJ100/36 +SJ65/36

The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

1, auto spiral screw feeder

2, drying hopper

3, siemens motor

4, aluminum heater

2,Mould for 1220mm PP hollow corrugated sheet co-extrusion machine

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

1, customized width and thickness

2, with hydraulic screen changer

3, with melting pump

4, high quality mold with precision thickness control

3,Calibrating table for 1220mm PP hollow corrugated sheet co-extrusion machine

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

4,Haul off device for 1220mm PP hollow corrugated sheet co-extrusion machine

There are two tractors. The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

5,Heating oven for 1220mm PP hollow corrugated sheet co-extrusion machine

the heating oven device is necessary for the PP hollow sheet to remove the stress of the sheet, the heating oven should be made by 304 stainless steel, the heating oven is equipped with separately temperature control system for each zone to ensure the heating to be uniform, 4 meter lengths of heating oven is necessary.

6,Corona treatment for 1220mm PP hollow corrugated sheet co-extrusion machine

The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

7,Auto Cutter for 1220mm PP hollow corrugated sheet co-extrusion machine

Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

8,Control cabinet for 1220mm PP hollow corrugated sheet co-extrusion machine

1, ABB inverter motor

2, Siemens contractor

3, Omron temperature control

4, English button

5, ventilation on each panel

6, number mark on each cable

FAQ

1. Why choose us

We are the first manufacturer in Qingdao to develop plastic extruders. We have 22 years of experience in mechanical manufacturing. What we pursue is machine quality and customer satisfaction.

We only choose qualified supplier -- Tongsan excellent partner

We work closely with world famous brand,your equipment can also be equipped with any famous brand as you wish,such as Siemens motor,ABB inventer,Omron temperature controller, Schneider electric devices,etc.

2. What service do we provide?

Perfect service system:

1.We will provide the Feasibility Analysis Report for your project.

2.We will provide the model selection and technical parameter of our machinery.

3.We will provide the design for the plant and electric power accounting for the facilities.

4.We will provide the design for plastic formula according to the products requirement.

5.We will provide the technology of plastic product surface treatment if need.

6.We will provide technique training for your operator.

7.We will provide solution for the production problem .

8.We will install and test the machine in customer's factory.

9.We will provide turnkey project to customers.

3. Payment terms

30% of the total amount should be paid by wire transfer as a down payment, and the balance (70% of the total amount) should be paid (at sight) before the delivery of the wire transfer or irrevocable letter of credit

4. Delivery terms:

4.1 Delivery terms: FOB Qingdao Port.

4.2 Delivery deadline: within 30-60 working days after receiving the advance payment, the seller shall notify the buyer to inspect. The seller should complete the packaging of the goods within 15 working days after receiving the full payment and be ready for shipment.

4.3 Supervised loading: The seller should inform the buyer of the exact loading time, and the buyer should arrange the scope of supervised loading.

5. Warranty terms:

5.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse

5.2 The seller shall guarantee that the service and spare parts are free of charge during the entire equipment warranty period.

5.3 LIFELONG service: After the 12-month warranty, the seller shall provide LIFELONG service for the sold goods, and the buyer shall pay for the required spare parts.

6. Inspection :

After the machine is completed, the seller should notify the buyer to inspect before delivery, and the seller guarantees that all the goods sold are of good quality. The seller does not bear the material cost of the machine inspection in the seller's factory. The buyer should come to the seller's factory for inspection, or the buyer can invite any third party to enter the seller's factory for inspection.

7. Installation and equipment debugging:

If the buyer needs it, the seller should send a team of technicians to the buyer's factory for full-line operation of installation and testing, and the buyer should lift the price of the entire food/location and group purchase information (aircraft, food, hotel, etc.), and charge the engineer 100 USD/day/engineer's cost.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23