Factory Fiber Laser Welding Machine Element Inductry Welder Handheld Type

Taizhou Huangyan Lipeng Machinery Mould Factory / 2022-06-23

- After-sales Service:Online Service

- Warranty:2 Years

- Application:Biomedicine, Electronic Industry, Automotive Industry, Powder Metallurgy, Manufacturing Industry

- Technical Class:Continuous Wave Laser

- Control:Automatic

- Power Density:Deep Fusion Welding

=== Base Info ===

- Model NO.:LS1LW

- Laser Classification:Optical Fiber Laser

- Type:Optical Fiber Transmission Laser Welding Machine

- Laser Power:1000W

- Laser Source:Raycus

- Laser Wavelength:1080nm

- Laser Welding Method:Continuous

- Minimal Beam Diameter:0.1mm

- Continue Working Time:16 Hours

- Transmission System:Fiber Optical Transmission System(Fots)

- Fiber Optical Length:10m Standard

- Cooling System Dimensions:Water Cooling

- Consumable:Filter Element Protective Lens

- Transport Package:Plywood Box

- Specification:1330*680*1390mm

- Trademark:Lansen

- Origin:China

- Production Capacity:300sets,Month

=== Description ===

Technical parameters

APPLICATIONS:

Used in kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel door and window industry, handicraft industry, home goods industry, furniture industry, auto parts industry, etc.

Service

1. Pre-sale Service

Before signing the contract, the company is free of charge for the customer product samples and technical and price consultation.

2. On-sale Service

If there is any technical problem in the process of product installation, you can contact the local regional manager or after-sales technical personnel at any time. If you need on-site technical support, you can communicate with the local sales manager and the company will coordinate and arrange.

3. After-sale Service

Within the scope of the warranty period of the contract, the response time of customer service is within 24 hours. During the warranty period, we will provide free and efficient technical service support for customers. After the warranty period, we will provide hardware and software support and enjoy free upgrade service of the software system for life.

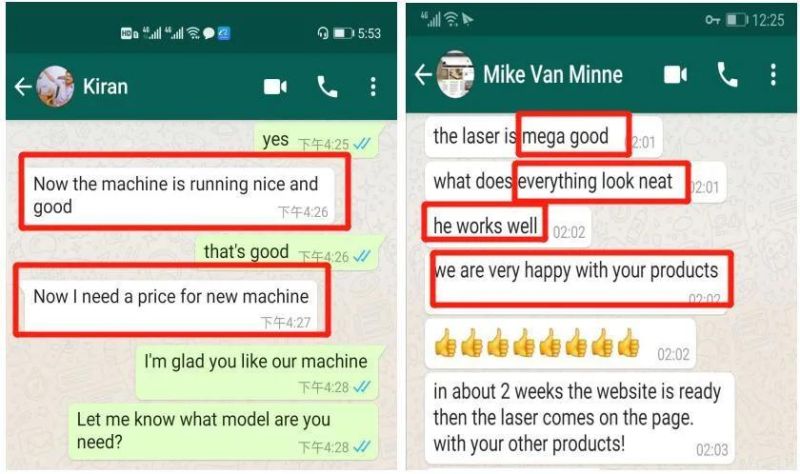

FEEDBACKS

COMPANY PROFILE

COMPANY PROFILE

FAQ and troubleshooting

1. The state of the laser head is not displayed: X.Y motor cable is loose, or 15V power input is interrupted, or the motor is damaged.

2. No on state display or intermittent light output during welding: it may be that the communication signal is not connected or the wire is loose and not plugged tightly, and the crocodile clamp does not form a loop with the X5 signal.Intermittent light may be due to the shaking of the nozzle during the welding process, or the plate rusted, not connected with the clamp.

3. The status of the welding torch is not displayed: it may be that the switch button of the welding torch tip is loose, the terminals are loose or the interface is unwelded.

4. Uncontrollable gas: the gas button on the touch screen is not closed, or the gas delay is set too high, or the positive and negative terminals of the air valve are connected in reverse.

5. The parameters of the handheld head LCD screen and the setting parameters of the touch screen are out of sync: the power supply input of the system 24V and the power supply input of the galvanometer 15V cannot be powered on at the same time, resulting in out-of-sync parameters and unable to update data.

6. Easy to burn the protective lens: the gas is not pure or no air pressure, the working environment is bad, the focus is off, the water cooling system is damaged, and other factors.During welding, the start and end delay of gas is set at about 150ms, and the focus position should be slightly off the positive focus, welding at about 2MM of negative defocus.

7. Overheat of welding torch head: the protective lens burns or the water circulation of chiller fails to pass or is caused by water fault.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23