ISO9001 Certified New Designed Chocolate Enrobing Machine (TYJ800)

SHANTOU DAFU PLASTIC PRODUCTS FACTORY CO., LTD. / 2022-07-04

- After-sales Service:Online Support

- Warranty:1 Year

- Certification:CE, ISO9001, BV

- Power Source:Electric

- Process:Concentration and Dry

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:chocolate enrober

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

- Name:Chocolate Enrober

- Mesh Belt Width:550mm

- Conveyor Belt Width:600mm

- Cooling Tunnel Length:16000mm

- Cooling Tunnel Temperature:0-10ºC

- Material:SUS304

- Coating Type:Full Coating,Bottom Coating

- Weight:2300kg

- Total Power:24.44kw

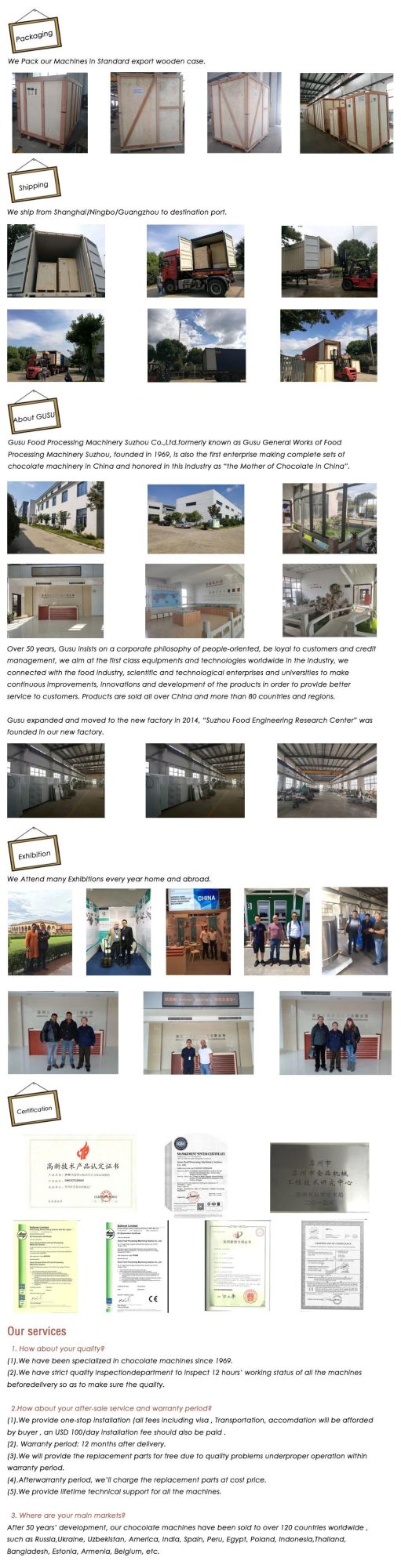

- Transport Package:Standard Export Wooden Case

- Specification:600mm

- Trademark:Gusu Machinery

- Origin:China

- HS Code:8348200000

- Production Capacity:5000 Sets,Year

=== Description ===

Gusu New Designed Chocolate Enrober Advantages

Machine appearance is similar to European equipment which is well-looking and more hommization.

Cover and closing board are designed simple and elegant which is easy for operate and maintain.

Chocolate Paste Hopper can be pushed and pulled very flexible. Easy to clean and leaving no dead angle.

The fan cover has a streamlining design to make the cooling more efficient and sufficient. The evaporator is specially designed(gained patent) to reduce the humidity of cooling tunnel effectively and make high quality chocolate.

This enrober can produce fully coated and half coated chocolate products. The thickness of coating area is controlled by fan speed and vibration.

The food grade PU conveyor belt has a automatic correction device and the whole line is controlled by PLC.

The length of the whole enrober line can be adjusted according to customer's requirements.

Combinatorial Arrangements

Automatic feed mechanism which can reduce operation staffs to improve production efficiency.

Patterns decorator which can make different colors of curve patterns coated on the surface to improve product level.

Material Spreader which can spread crushed peanut, sesame or other nuts granules on the chocolate surface to enhance flavors

Contact us

Contact person:Bob Shi

Website: gusumachinery.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23