PC Multiwall Hollow Sheet Extrusion Line

Xinzheng Lifa Abrasives & Abrasives Co. Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Item

Description

Data

1

SJ120/35 Single screw extruder with stainless steel hopper

1 set

2

Screen exchanging unit for PC

1 set

3

Melting gear pump for PC

1 set

4

SJ45/30 Single screw extruder for UV layer

1 set

5

Melting gear pump for uv

1 set

6

T-type Die head (2100mm*4-6mm)

1 set

7

Vacuum calibrating board

1 set

8

cooling table

1 set

9

The first haul off machine with 12 rollers

1 set

10

edge cutting device

1 set

11

5000mm oven

1 set

12

Corona treating unit

1 set

13

up and down sides, double position film laminating device

1 set

14

The second haul off machine

1 set

15

Tranverse cutting machine (length-settled)

1 set

16

material conveyor+6000mm discharge table

1 set

17

eletrical cabinet

1 set

other accessory machine parts

18

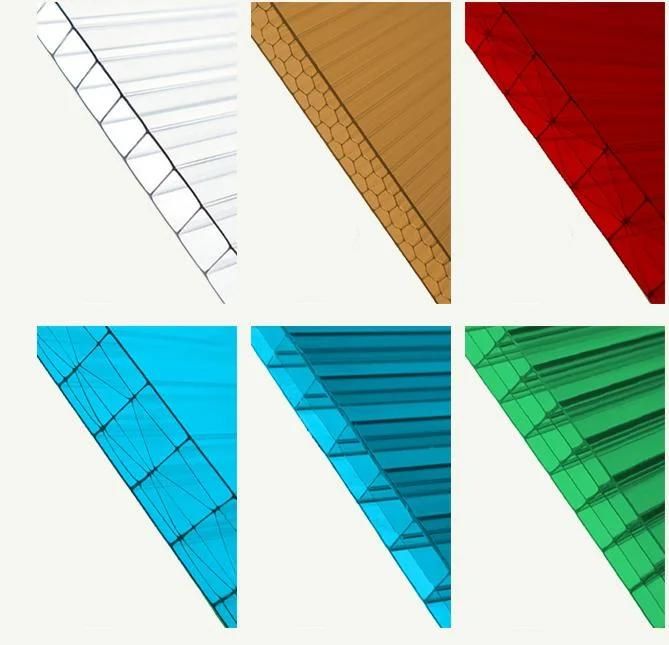

PART 3 SHEET APPLICATIONS:

1) Sunshades for stadium and bus shelters

2) Lighting for corridors, passages and subway entries

3) Bank ATMs

4) Sound and heat insulation for construction such as: houses

5) Canopies for agriculture greenhouse, zoos

6) PC sheets mainly used for building and decorating materials, greenhouse material, telephone booth, insulation shield express

ways & highways

7) Office building, hotels, villas, stadium, schools, bus stop, terminals, hospitals, subway entry and exit doors, etc.

PC hollow sheet introduction

polycarbonate is best known for its very high impact resistance, fine optical clarity and excellen fire performance.

hollow polycarboante is also often named as strutural polycarbonate, cellular polycarbonate, channel polycarbonate or multiwall polycarbonate.polycarbonate hollow sheets offer the higher level of glazing performance where transparency

along with high impact strength is of vital importance. They have excellent physical, mechnical, electric as well as hot

property which explains their high reputation in buildings

and decoration industry. They are sold all over the world, making great contribution to customer's beautiful life.

UV protection

solar radiation has a harmful component by UV rays which initiate degradation of many polymetric material including

polycarbonate.This depends on geographic locations, seasons etc. Polycarbonate sheets feature a specifically co-extruded

UV absorption and protection layer, which provides long-lasting high stability against demanaging UV radiation, protects

againts outdoor weathering and retains its original color and light transmission.

MORE MACHINE PICTURES:

PART 5 SAMPLE PICTURES:

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS

OUR COOPERATED SUPPLIER LIST

PART 10 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

Best regards!

Sincerely yours,

Lilly Zhou, Sales Manager

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23