Hot Selling Double Screw Fruit Press Machine Spiral Juice Extractor Apple Juicer Machine

KAYA INTERNATIONAL HK LIMITED / 2022-07-05

- Type:Cutter

- Voltage:380V

- Power:1.5KW

- Customized:Customized

- Output:0.5t,H

- Spiral Diameter:88mm

=== Base Info ===

- Model NO.:ZZJ-1

- Crushing Motor Power:1.5kw

- Main Motor Power:1.5kw

- Filter:0.6mm

- Dimensions:780*380*800

- Keywords 1:Fruit Juicer Extrator Machine

- Keywords 2:Fruit Juicer Machine

- Keywords 3:Fruit Juicer Extrator

- Keywords 4:Fruit Juice Extrator

- Keywords 5:Juicer Extractor Machine

- Transport Package:Wooden Case

- Specification:780*380*800

- Trademark:AG

- Origin:China

- Production Capacity:20 Sets Per Month

=== Description ===

Basic Info.

Model NO. ZZJ-1 Crushing Motor Power 1.5kw Main Motor Power 1.5kw Filter 0.6mm Dimensions 780*380*800 Keywords 1 Fruit Juicer Extrator Machine Keywords 2 Fruit Juicer Machine Keywords 3 Fruit Juicer Extrator Keywords 4 Fruit Juice Extrator Keywords 5 Juicer Extractor Machine Transport Package Wooden Case Specification 780*380*800 Trademark AG Origin China Production Capacity 20 Sets Per MonthProduct Description

Hot Selling Double Screw Fruit Press Machine/Spiral Juice Extractor /Apple Juicer Machine

Use and scope of application:

1.Used to squeeze pineapple, apple, pear and other fruits;

2.For pressing tomatoes, ginger, garlic, celery and other vegetables.

3.Spiral propulsion;

4.Fully automatic berry, pome fruit and vegetable fruit and vegetable juice extraction and slagging process;

5.The part in contact with the material is made of GB 304 stainless steel.

6.The frame material can be selected from the national standard 304 stainless steel, depending on customer requirements.

Specification of Juice Extractor:

| Specification | Output | Spiral diameter | Crushing motor power | Main motor power | Filter | Dimensions |

| AG-0.5TG | 0.5T/H | 88mm | 1.5kw | 1.5kw | 0.6mm | 990*380*1100mm |

| AG-0.5T | 0.5T/H | 88mm | / | 1.5kw | 0.6mm | 780*380*800mm |

| AG-1.0TG | 1T/H | 125mm | 1.5kw | 3kw | 0.6mm | 950*350*1200mm |

| AG-1.0T | 1T/H | 125mm | / | 3kw | 0.6mm | 909*320*833mm |

| AG-1.5TG | 1.5T/H | 175mm | 2.2kw | 7.5kw | 0.6mm | 1400*550*1700mm |

| AG-1.5T | 1.5T/H | 175mm | / | 7.5kw | 0.6mm | 1400*500*1380mm |

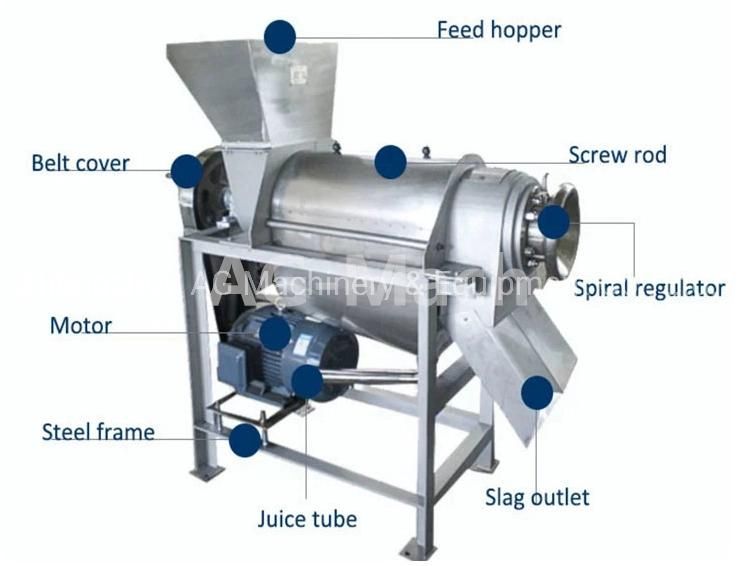

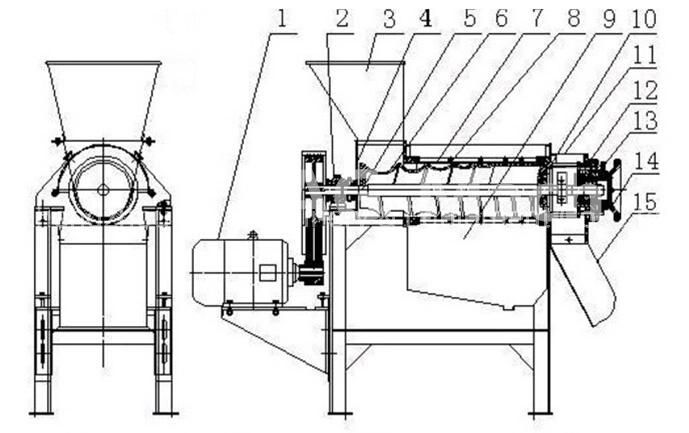

Detailed of Juice Extractor:

1. Motor 2. Bearing housing 3. Feed hopper 4. Front support

5. Spindle 6. Spiral 7. Filter 8. Skeleton

9. Juice extractor 10. Pressure regulator 11. Rear support

12. Press seat 13. Brake pin 14. Hand wheel bearing 15. Slag bucket

Equipment structure of Juice Extractor:

1.Structure: It consists of front support, feed hopper, crushing, spiral, filter net, juice extractor, rear support, slag sump, etc.

2.The left end of the spiral main shaft is supported in the rolling bearing housing, and the right end is supported by the hand wheel bearing.

3.In the seat, the motor is driven by a pair of V-belt drive screws.

Performance characteristics of Juice Extractor:

1. Advanced design, compact structure and beautiful appearance.

2. The machine is composed of two parts: crusher and spiral juice extractor, which fully completes the process of crushing, juicing and slagging.

3, the use of conical screw, large capacity, high juice yield.

4, high efficiency, low noise, no pollution.

5. The parts in contact with the materials are all made of stainless steel;

Working principle of Juice Extractor:

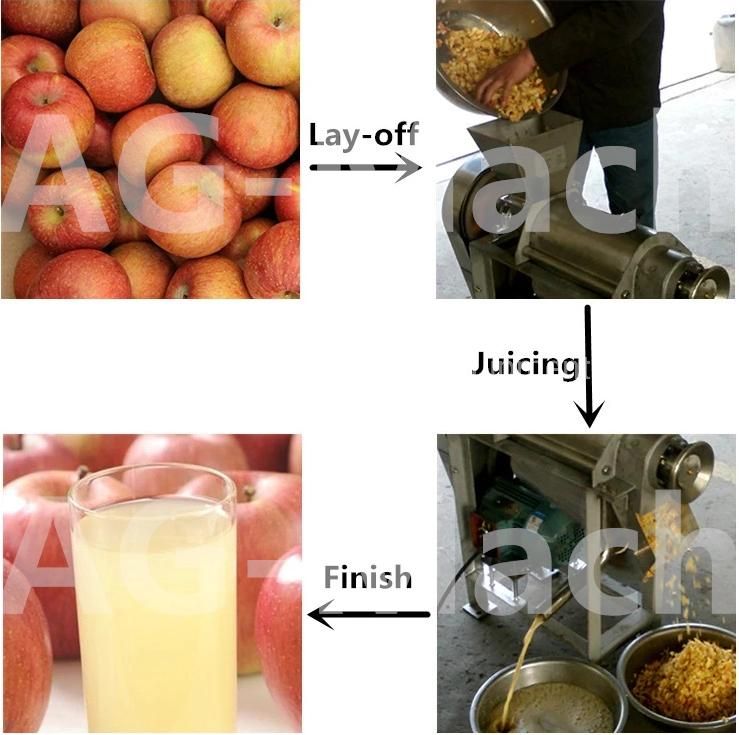

1.The main component of the equipment is the broken pulp, juice and skin entering the spiral juice extractor through the feeding hopper.

2.The spiral diameter gradually increases along the direction of the slag outlet and the pitch gradually decreases.

3.When the material is spirally advanced, the spiral is caused by the spiral.

4.The volume of the cavity is reduced to form a press of the material.

5.The direction of rotation of the helical main shaft is viewed from the feed hopper toward the slag groove in a clockwise direction.

6.The raw material is added to the feed hopper, pressed under the advancement of the spiral, and the pressed juice flows through the filter into the bottom of the juice extractor, and the waste is discharged through the annular gap formed between the spiral and the tapered portion of the pressure regulation.

7.The movement of the pressure regulating head in the axial direction can adjust the size of the gap.

8.For clockwise (when the seat is turned from the tapping groove of the device to the end of the feed hopper, the head is turned to the left, the gap is reduced, and the gap is enlarged.)

9.The size of the gap is changed, that is, the row is adjusted.

The resistance of the slag.

10.The slag removal rate can be changed, but if the void is too small, under strong extrusion, some of the slag particles will be extruded through the filter together with the juice.

Package of Juice Extractor:

Features of Juice Extractor:

1.The motor drives the spindle to rotate through a pair of pulleys.

2.The tripod is mounted on the spindle. The beater plate is on the tripod.

3.The screen, funnel and slag are mounted on the lower bracket.

4.The upper inner cylinder and the feeding hopper are loaded on the bracket, and the entire upper bracket is hingedly connected, and can be opened to check the quality of the pulp.

Preparation before use:

1. Stabilize the machine on the foundation and tighten the screws on the chassis feet;

2. Open the cylinder, clean up the debris, and clean it. When cleaning, do not leak the water to the motor;

3. Adjust the gap between the scraper and the inner wall of the screen to be 1.5~2mm;

4. Adjust the spiral angle of the scraper;

5, whether the spindle is flexible by hand, cover the upper cylinder tightening screw;

6. Before feeding, the skin of the thick skin should be peeled. Such as: orange, large nuclear fruit to go nuclear, such as: peaches, long vegetables to cut, garlic dishes to cut, big peppers to cut open, and all must be fresh.

7. The fruits and vegetables to be processed must be cleaned.

8. Turn on the power. Start the motor, test the juice extractor, check whether the spiral direction of the spindle is correct, whether the sound is normal, and so on.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23