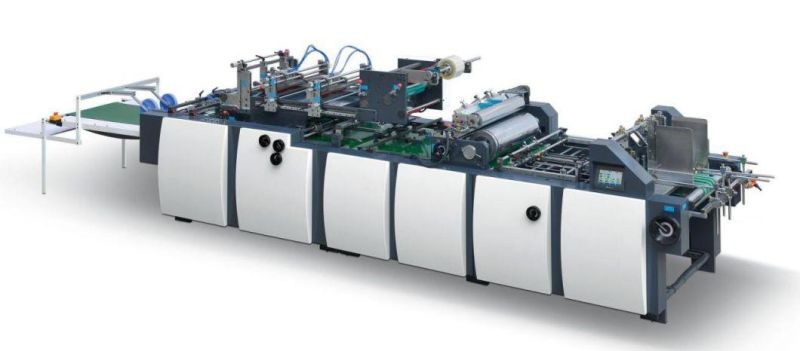

High Speed Automatic Window Patching Machine Can Be Customized to 1300 Width Size with Creasing Line Function

Zhejiang New Luolan Machinery Co., Ltd. / 2022-06-27

- Species:Window Patching Machine

- Automatic Grade:Automatic

- Max. Paper:1080X680mm

- Min. Paper:140X140mm

- Max. Film:380X450mm

- Min. Film:68X30mm

=== Base Info ===

- Model NO.:GK-XY1080

- Film Thickness:0.05-0.2mm

- Applied Paper:Cardboard 200-800g

- Applied Corrugated Paper:≤7mm

- Max. Speed:5000-6000 Pieces,Hour

- Total Power:16kw

- Machine Weight:3200kg

- Transport Package:Seaworthy Packaging

- Specification:5x1.96x1.75m

- Trademark:RAGAOKE

- Origin:Wenzhou

- HS Code:8441309000

- Production Capacity:40 Sets,Month

=== Description ===

Basic Info.

Model NO. GK-XY1080 Film Thickness 0.05-0.2mm Applied Paper Cardboard 200-800g Applied Corrugated Paper ≤7mm Max. Speed 5000-6000 Pieces/Hour Total Power 16kw Machine Weight 3200kg Transport Package Seaworthy Packaging Specification 5x1.96x1.75m Trademark RAGAOKE Origin Wenzhou HS Code 8441309000 Production Capacity 40 Sets/MonthProduct Description

ZHEJIANG NEW LUOLAN MACHINERY CO., LTD.New Luolan Machinery, the leader in gluing and folding field!

Zhejiang New Luolan Machinery Co., Ltd, whose previous name is Ruian Gaoke Machinery, is established in 2006. As a professional manufacturer, we not only do manufacturing, but also researching, marketing and offering after sales service. We supply quality equipment, effective and convenient solutions for cardboard box and corrugated box folding industry, printing and packaging industry. Gluing folding machine and window patching machine which produced by Zhejiang New Luolan Machinery Co., Ltd have approved by the National Quality Supervision and inspection.

New Luolan Machinery, persists on keeping pace with the times and expanding market with all our strength. We will be continuously devote to providing higher quality products and more satisfactory service in return for the support and favors of our customers.

XY1080 Automatic High Speed Corner Cutting window patching machine

Note:The size can be customized to 1300mm in width with creasing line.The simple window patching(GK-1080T)can abe customized to 1800mm in width.

XY1080 Corner cutting Window Patching Machine is widely used in the film patching to be package with or without the window of the wine box .gift box. napkin box. cosmetic box etc. It can also realize the function of the paper gluing ,film patching ,film cutting and paper collection before folding boxes.

The machine has passed the ISO9001 Quality System Certificate and conform the European CE safety standard.

Features of the machine

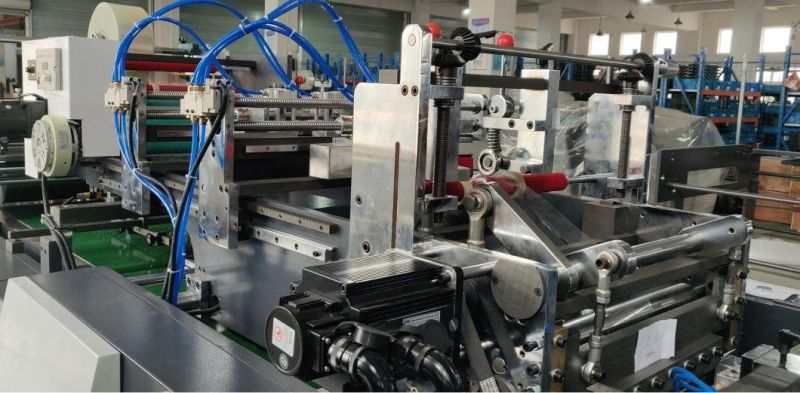

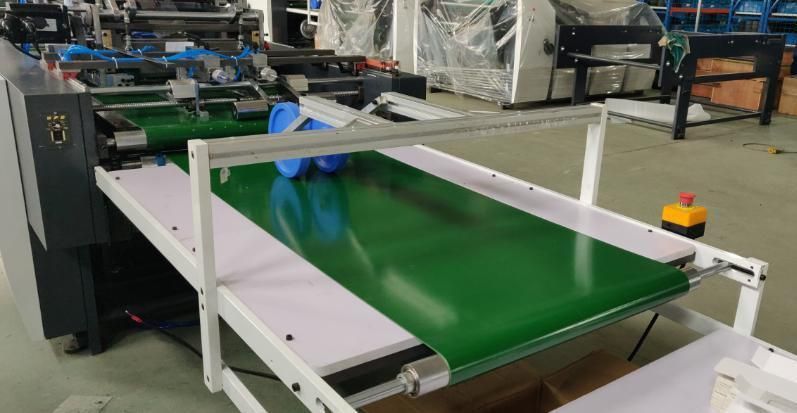

| Paper Feeding Section The paper feeder parts is controller by the servo motor, the paper pile make the intermittent movement in the process of the paper feeding, the belts operate long life ,process the paper products to the conveying parts steady and orderly. Perfect for the cardboard and corrugated.  Conveying Section Double paper servo control The paper conveying parts installed the four conveying chains with the four pushing blocks, it can be adjusted according to the paper shape. It is equipped with the 4 photo sensor, detect the paper reaching condition, counting , paper jammed detection.  Gluing Section The gluing parts adopt the adjustable parts gluing structure , it is convenient for adjustable according to the paper requirement and the gluing position ,save the gluing quantity. It is easy for pulling out the gluing parts ,convenient for washing. The gluing roller stopped the gluing when stopped the machine. And the conveying parts dropped automatically, the gluing is not easy to print on the conveyor belts.  Creasing and punching Section Automatically Punching and creasing, position of the film can be adjusted no-stop.Ensure that even the machine in high speed operation, running steady and high efficiency.  The pressure of creasing can be adjusted for many different films. Feeding film is controlled by separate servo which make us can adjust the film length no-stop. With front-lay positing to accurately position the paper. The precision up to±0.5mm.  Paper Collection Section The patching products conveying to the paper delivery plate, finish the paper accumulation and collection Paper delivery parts can be adjust single.  |

Electrical Component

|

|

|

|

|

|

|

|

|

|

|

>>> Exhibition Show

>>> Company Introduction

New Luolan Machinery, the leader of gluing and folding field.

New Luolan Machinery Co.,Ltd,whose previous name was Ruian Gaoke Machinery, was established in 2006.As a professional manufacturer,we not only do manufacturing, but also do researching ,marketing and offering after sales servicerd b.We supply quality equipment,effective and convenient solutions for cardboaox and corrugated box folding industry,printing and packaging industry,We have got CE certificate in 2008.

We persist on business philosophy of technology and innovation,casting quality and pursuit of excellence.

Since the establishment of the company,we pay attention to developing and bringing in professional technicians and setting up a young elite team, our products are quite popular in southeast Asia and Europe because of high quality.

Ten years witnesses our growth.Now our company space covers more than 10000 square meters. There are more than 80 employees.Two of them have master degree, ten of them have bachelor degree, more than 20 received professional training.

Add: No.18 Wansheng Road, Wanquan Ind. Zone, Pingyang, Zhejiang, China

Postal Code: 325400

>>>Shipping &Packing

Normally, we use wooden pallets and cases, we use fumigation/ free fumigation wooden pallets and cases for some European countries, also some are according to the customer's requirement.

>>> RFQ

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes.

3.Q:What is the production time while placing order?

A:About 30 days

4.Q:What is the delivery time?

A:Within 30 days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6.Q:Does the packing strong?

A:Yes, of course! All of our export packing is with strong wooden pallets, all are confirmed to export packing standard.

7.Q:How about after-sales service process?

A:When your machine has problem, contact your sales and we will solve your problem soon as possible.

8.Q:Are you manufacturer?

A:Yes, we are manufacturer with 10-year experience and profession.

9.Q:Do you have stock product to sell?

A:Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need custom one for you, and your order will be highly attention to manufacture.

10.Q:Do you inspect the finished products?

A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .

11.Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

We are professional manufacturer since 2005. We believe our products will provide you with great business benefits and advantage.

Our faith:

1) Society's Avail First

2) Client's Avail First

3) Employee's Avail First

4) Enterprise's Avail Second

If you have any inquiry, please don't hesitate to contact us. We will reply to you at the first time as we can.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23