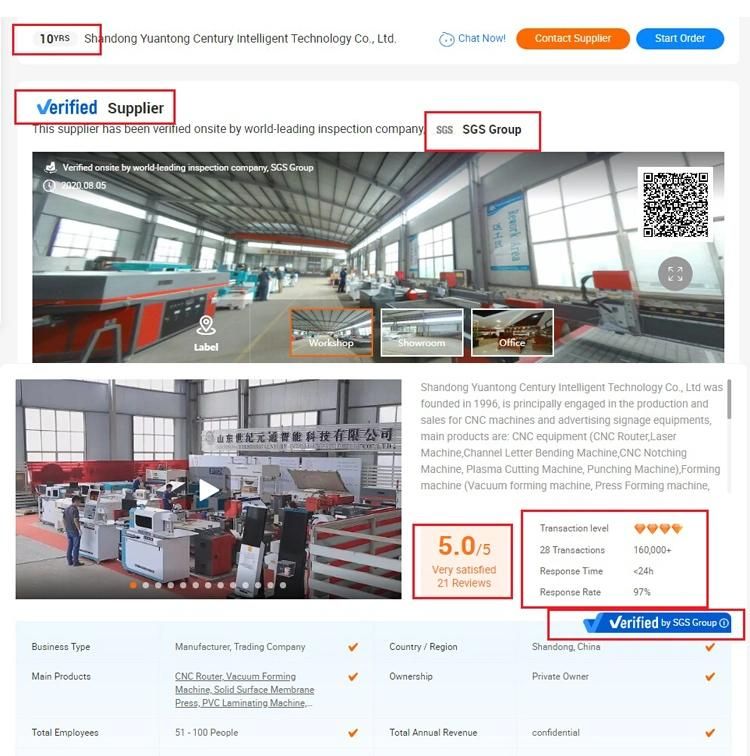

Full Automatic Lid Plastic Vacuum Cup Thermoforming Forming Machine

Xiamen ZL Diamond Technology Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

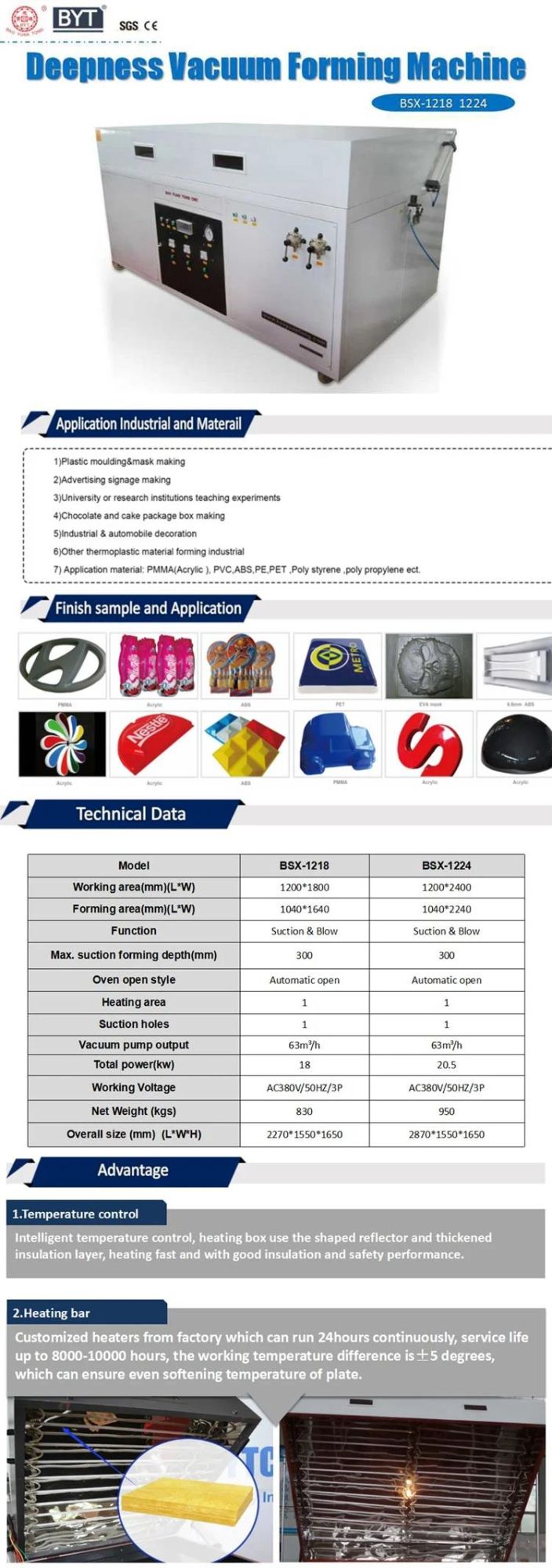

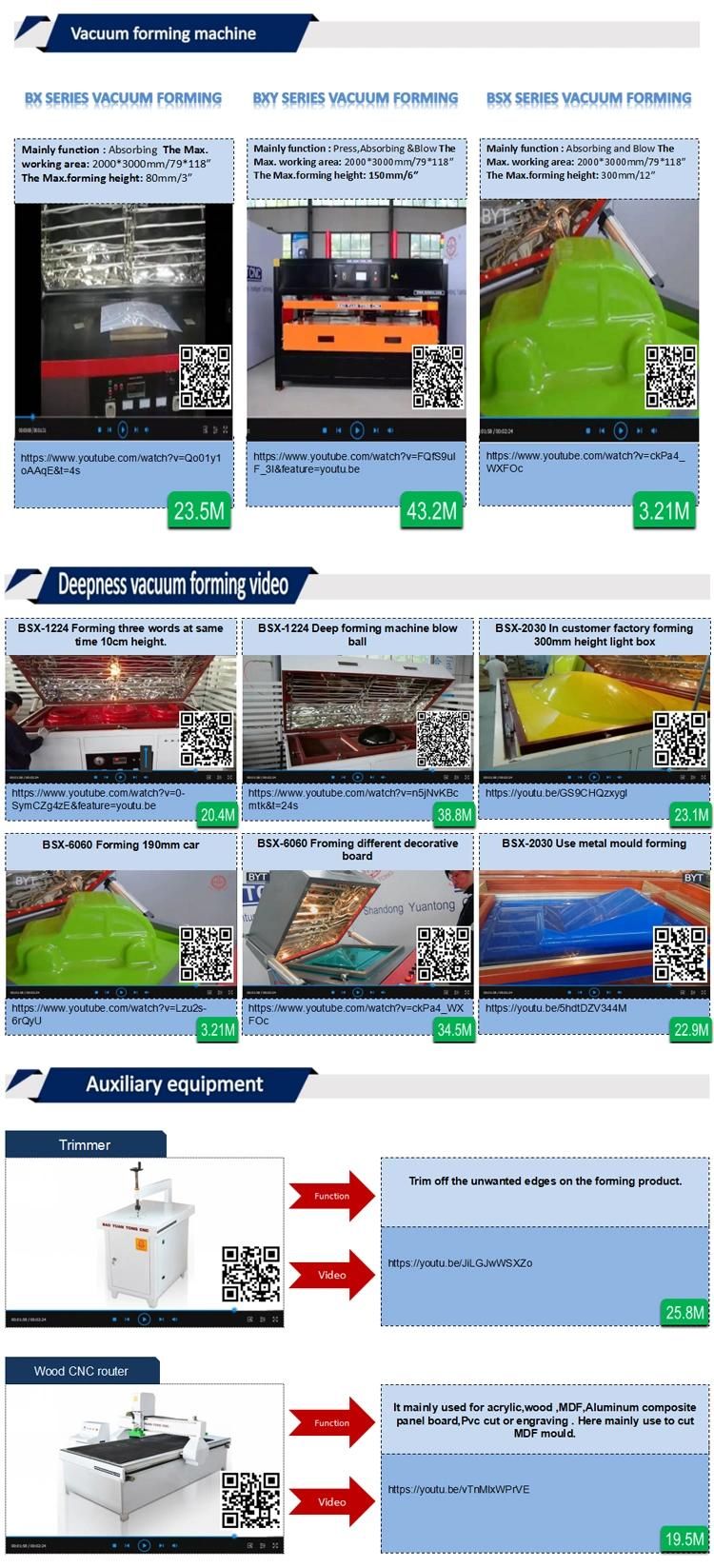

Model NO. BSX-1224 Certification CE, SGS Working Area 1200*2400mm Forming Area 1040*2240mm Max Forming Height 300mm Total Power 20.5kw Vacuum Pump Output 63m3/H Working Voltage 380V/50Hz/3p or Customized Net Weight 950kg Transport Package Wooden Box Specification 2870*1550*1650mm Trademark BaoYuanTong Origin Shandong Production Capacity 200sets/MonthProduct Description

Plastic Vacuum Forming Machine for Acrylic, ABS, PVC, thermoplasticApplication Industry and material :

1)Plastic moulding&mask making

2)Advertising signage making

3)University or research institutions teaching experiments

4)Chocolate and cake package box making

5)Industrial & automobile decoration

6)Other thermoplastic material forming industrial

7) Application material: PMMA(Acrylic ), PVC,ABS,PE,PET ,Poly styrene ,poly propylene ect.

Feature:

1.Intelligent temperature control, heating box use the shaped reflector and thickened insulation layer, heating fast and with good insulation and safety performance.

2. Customized heaters from factory which can run 24hours continuously, service life up to 8000-10000 hours, the working temperature difference is±5 degrees, which can ensure even softening temperature of plate.

3.Working platform is made of steel which is high temperature resistant and long life service.Adopt single mould forming, easy operation, lower raw material and labor cost.

4. The aluminum alloy press frame controlled by two cylinders is more convenient to use and improves the sealing and forming effect.

5.Add movable platform controlled by two cylinder to ensure smooth lifting & increase the molding height.

6.More powerful vacuum pump , finish vacuum forming sample more beautiful

7.Air storage tank is installed to extend the service life of vacuum pump, at the moment of moulding, the suction force is stronger and the forming effect is better.

8.Add blowing function, not only easy to demoulding, and can complete the ball blow molding.

Technical data:

| Model | BSX-1218 | BSX-1224 | BSX-2030 |

| Working area(mm)(L*W) | 1200*1800 | 1200*2400 | 2000*3000 |

| Forming area(mm)(L*W) | 1040*1640 | 1040*2240 | 1840*2840 |

| Function | Suction & Blow | Suction & Blow | Suction & Blow |

| Max. suction forming depth(mm) | 300 | 300 | 300 |

| Oven open style | Automatic open | Automatic open | Automatic open |

| Heating area | 1 | 1 | 1 |

| Suction holes | 1 | 1 | 1 |

| Vacuum pump output | 63m³/h | 63m³/h | 100m³/h |

| Total power(kw) | 18 | 20.5 | 34 |

| Working Voltage | AC380V/50HZ/3P | AC380V/50HZ/3P | AC380V/50HZ/3P |

| Net Weight (kgs) | 830 | 950 | 1680 |

| Overall size (mm) (L*W*H) | 2270*1550*1650 | 2870*1550*1650 | 3550*2250*1650 |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23