Imitation PVC Artificial Marble Board Equipment

Yueqing Weiao Import & Export Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ80, SJSZ92 Computerized Non-Computerized Certification CE, ISO9001:2008 Customized Customized Condition New Name PVC Artificial Marble Board Equipment MOQ 1 Set Features Excellent Quality Motor 55kw Inverter Taida, ABB Temperature Controller Omron Low Voltage Units Siemens Transport Package Wrapping with Plastic Film Specification SJSZ80/156, SJSZ92/188 Trademark Qingdao Sunshine Machinery Origin Qingdao, China HS Code 84772090 Production Capacity 350-450kg/HProduct Description

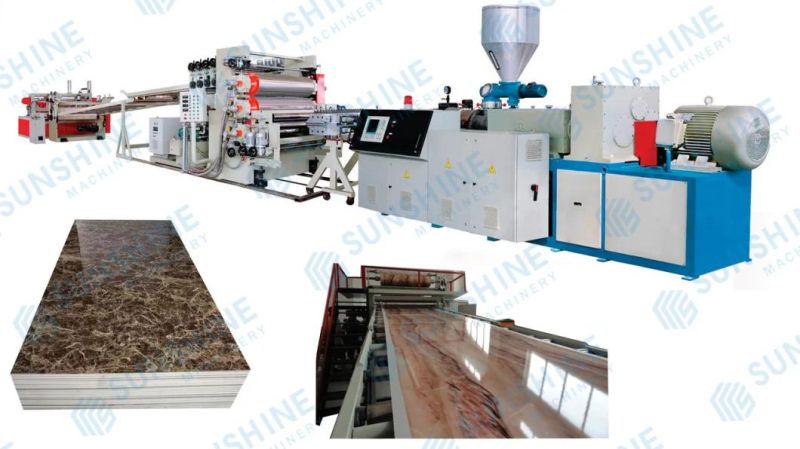

Imitation PVC Artificial marble board equipment Brief introduction of imitation PVC Artificial marble board equipment

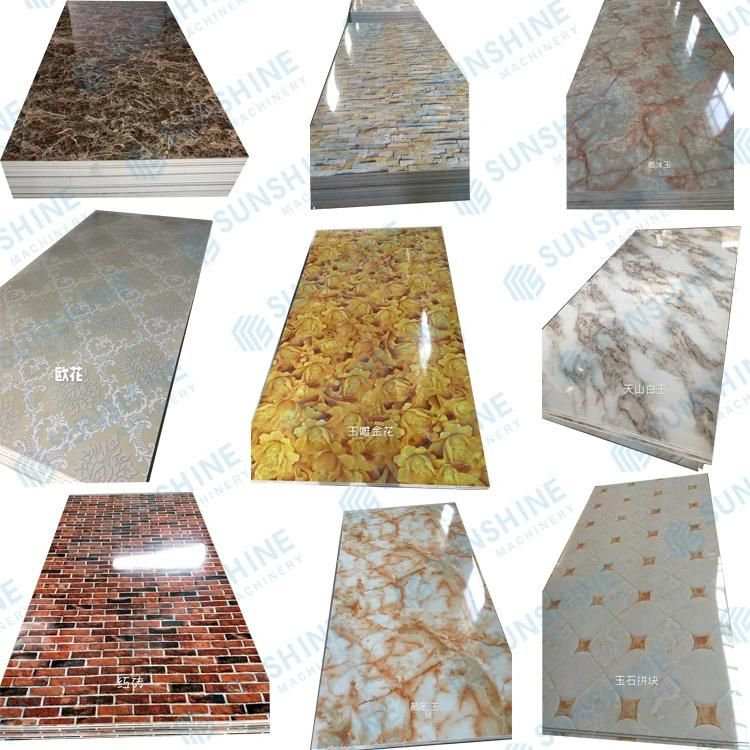

Brief introduction of imitation PVC Artificial marble board equipmentWith the improvement of people's living standard, marble is favored by more and more people for its plain and elegant decorated decorative styles, how ever, its usage rate is not high in traditional decoration because of high cost. In order to pursue more fashionable decoration concept, PVC artificial marble sheet emerged.

It has delicate marble texture, color and glossiness. What's more, it has low price and convenient construction, and is a new eco-friendly material of modern home decoration without radiation.

Manufacturing process of imitation PVC Artificial marble board equipment

All this comes from the manufacturing process.

Firstly, the main materials of the PVC artificial marble sheet are PVC and calcium carbonate and other chemical auxiliaries.

Mixing these powders together is the first process of the PVC artificial marble sheet manufacture.

The function of the high speed mixer is to uniformly mix various raw materials and discharge the moisture from materials.

The uniformly mixed materials are cooled to 40-55ºC and discharged by low speed mixer.

The uniformly mixed PVC material enters hopper of twin screw extruder by feeding machine.

The function of the twin screw extruder are: Heating, pressurization and plasticizing controlled extrusion.

The production line adopts PLC control, has built-in PLC modules, and achieves interaction of machine information and man-machine automatic control.

Material extrude out from a T type die and through three rollers calender for shaping process, which is a key step of the PVC artificial marble sheet forming.

Introducing foreign technology and industrial production experience.

Three roller calender formation is used. The 3 roller calender comprise two mirror face rollers and one embossing roller, which is the necessary condition of 3 roller formation.

It uses Taida series inverter and PLC touch screen intelligent linkage control to ensure efficient combination of equipment and orderly 3 roller formation.

The shaping process is to cooled the PVC artificial marble sheet and make it has base body.

Then first roller film hot stamping, which function is increasing the toughness and beautification of the PVC artificial marble sheet to make it have various presentations and fit different decorative styles.

This is the prototype of the PVC artificial marble sheet.

The two roller traction is to accurately drag the PVC artificial marble sheet to cutting machine for cutting.

It adopts internationally advanced two-roll traction technology for precise localization, so as to facilitate uniform cutting.

The cutting machine adopts computer control technology for refined cutting aiming at products of different levels.

The cutting part adopts fixed-scale cutting device, which has the most obvious advantage of preciseness and fineness and ensures that each piece of cut product is uniform.

After multiple processing techniques, perfect PVC artificial marble sheet is generated, at this time, automatic loader will actively lift the sheet, stack it in finished product area, and ensure orderly proceeding of complete process.

About us

About us

Our partners

FAQ:

FAQ: 1. Are you a factory or trade company?

We are the all in one company with factory and trade. So one sentence, we are the real factory, you are warm welcome to come and visit us at any time.

2. What can you buy from you?

Plastic extrusion machines, such as the imitation PVC artificial marble board equipment, PVC|WPC foam board machine, PVC solid|hollow door frame machine, PVC window and door profile machines, PVC edge banding machine, PVC sealing strip machine, PVC ceiling machine, PVC|WPC wall panel machine, PET|PP strapping band machine, PE PP PPR PERT pipe machine, PVC PP PE single|double wall corrugated pipe machines etc. related the auxiliary machines.

3. What about your after sales.

6 months for the electrical units, 12 months guarantee for the main machine (except for the quick-wear parts)

If anything we can help, welcome to contact us by made in china trade messenger!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23