Large Hydraulic Cylinder Support for Mining Use

ZHEJIANG MAYEN PACKING CO., LTD. / 2022-06-27

- Certification:ISO9001, ISO,Ts16949:2009, ABS, API

- Pressure:Medium Pressure

- Work Temperature:Normal Temperature

- Acting Way:Double Acting

- Working Method:Straight Trip

- Adjusted Form:Switching Type

=== Base Info ===

- Model NO.:Z068-30

- Structure:Piston Type

- Material:Carbon Steel, 27simn, Alloy Steel

- Name:Hydraulic Column Support

- Surface Treatment:Electric Galvanizing

- Color:According to Your Requirements

- Working Pressure:37.5MPa

- Mounting Distance:1200mm

- Effective Resistance:1300kn

- Setting Load:1090kn

- Delivery Time:15-20 Days

- MOQ:1 Piece

- Transport Package:Pallets,Plywood

- Specification:CE

- Trademark:WTJX , OEM

- Origin:Shandong, Rizhao

- HS Code:8412210000

- Production Capacity:200, 000 Sets

=== Description ===

We firmly believe that quality products from the outstanding design and concept, there are 25 engineers with rich experience in our strong technical team and more than 9,000 types of design. Analyzes, calculations, strength check and motion simulation in variety of software to make our design more close to actual working conditions, We will consider various factors in the design stage to avoid each risk of project failure. Our design and products could perfectly match customers' varied needs.

No.3 Advantage

1. Warranty period:

Wantong Hydraulic warrants all cylinders to be free from any defects in material or workmanship under normal use and service for a period of 14 months.

2. Exclusion clause:

This warranty does not cover & WANTONG shall have no responsibility for:

- Troubleshooting, diagnostic, removal, or reinstallation labor charges;

- Freight charges for either defective parts or new or repaired parts unless prior written approvalis obtained from WANTONG;

- Claims for loss of time, inconvenience, loss of use, profits or other consequential damages;

- Conditions from, alteration, accident, misuse, neglect, fire, theft, loss, intentional damage, direct,indirect, consequential, incidental, weather related, or any other type of damage resulting fromthe use of the product;

- Corrosion unless the material is found to be out of specification;

- Failure due to contamination introduced to the cylinder;

- Paint unless out of specification;

3. Diagnostic:

After customers giving a feedback on product quality problems through the network or telephone, wantong companies will reply within 24 hours; We make every effort to make a diagnosis within 3-5 days or communicate with customers to do a detailed program. Wantong technology and quality departments have the responsibility to confirm the customer's question, for troubleshooting.

While customers would better provide as much as possible the product use of operating conditions, product damage photos, video, etc., to accurately determine the product problem and prevent similar problems in the future.

4. Accessories occur problems at warranty period:

1) If the customer is anxious, then we can provide free of charge within 5-20 working days [NOTE: According to the parts model, whether have inventory or purchase cycle], air freight should be beard by the customer.

2) If the customer is not anxious, it is recommended that sending the part to him in the next batch of orders, free of charge.

5. Hydraulic cylinder problems occur at warranty period:

1) New cylinder replace;

2) price discount in the next order;

3) the "repair fee" pay: repair fee required to within a reasonable range: the cost of wantong repair problem hydraulic cylinder < repair fee < the cost of production of a new hydraulic cylinder;

4) for strategic customers, one to one special treatment.

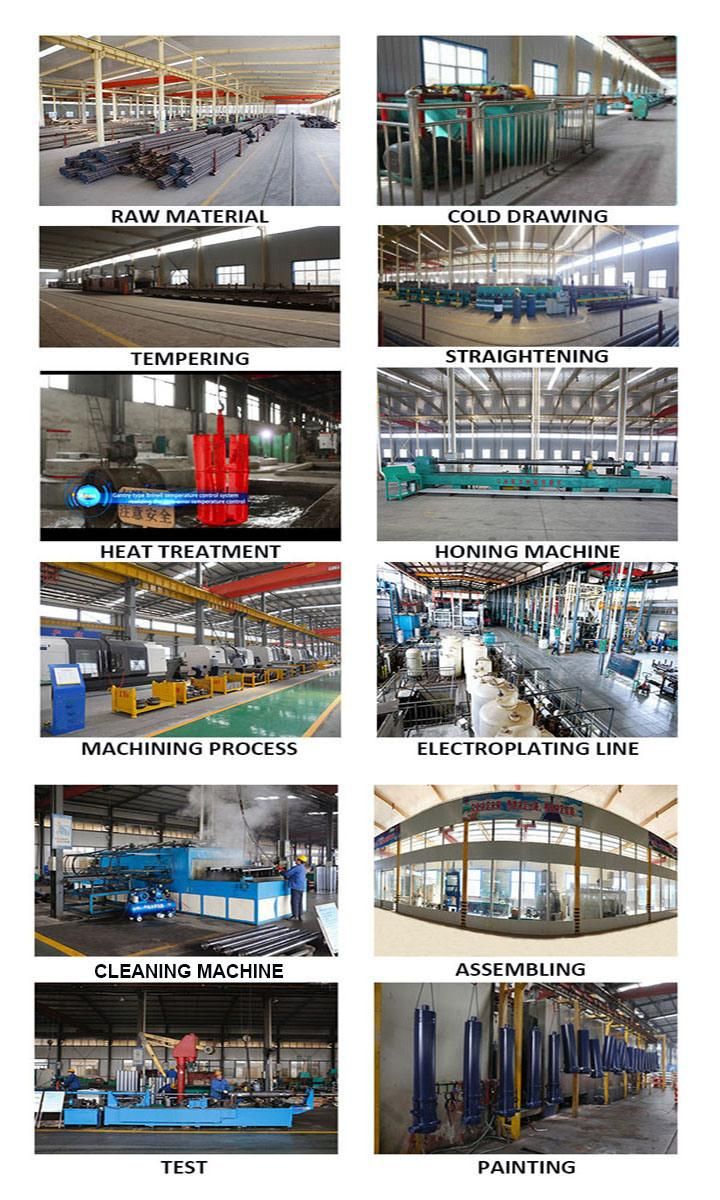

1) Raw Material

2) Cold Drawing

3) Tempering

4) Straightening

5) Heat Treatment

6) Honing Machine

7) Scraping Rolling

8) Machining Process

9) Electroplating Line

10)Cleaning Machine

11)Assembling

12)Test

13)Paining

14)Packing

>Owned plating plant founded in 1998;

>Owned honed tube plant founded in 2000;

>Owned Heat treatment founded in 1995;

>Each processing under our control, each products,every step under strict quality control;

No.5 Advantage

1) Professional, skilled, reliable.

2) One-stop total solution

3) Ready stock goods with fast delivery

4) Customizable: Non-standard sizes are also available

5) Small quantity is acceptable

6) Refund or replacement for any product faulty

No.6 Strict Quality Control System And Certificates and Packaging

1. Trial Operation Test

2. Start-up Pressure Test

3. Pressure-Tight Test

4. Leak Test

5. Full Stroke Test

6. Buffer Test

7. Testing the Effect of Limit

8. Load Efficiency Test

9. Reliability Test

Every piece of hydraulic cylinder are tested and will send out only after they are pasted the each test

Our company has abundant technical force and perfect testing means. By making wide technical and business cooperation with many related enterprises, universities, colleges and institutes both at home and abroad, and employing senior engineers and software engineers, we have greatly strengthened and improved our designing, processing, and testing abilities.

- The mechanical properties and chemical elements of the raw material will be inspected to check whether qualified after entering the warehouse.

- Chemical composition inspection of raw materials, Test the chemical composition of metallic materials, such as C, Si, Mn, P, S,Cr, Ni and other elements. Mainly for raw materials incoming inspection, by testing whether the material qualified, receiving materials.

- Metallographic analysis of metal materials is usually the raw materials, such as copper, iron, aluminum, magnesium, zinc, titanium, etc., for the processing of structural parts and finished product evaluation, through the metallographic analysis, You can find a variety of possible reasons for failure analysis in time, Prediction and analysis the characteristics of metallic materials and materials, Study material surface and internal defects, and to improve and verify the process technology of the material;

- Salt spray test is a major use of salt spray test equipment created by the artificial simulation of salt spray environmental conditions to assess the corrosion resistance of products or metal materials, environmental testing

- Mechanical performance testing equipment can meet the requirements of mechanical testing, all the use of computer digital display, so theaccuracy is more accurate, so that the mechanical properties of each cylinder barrel has been greatly improved.

- Every workpiece is machined according to the confirmed drawings and will be inspected casually by QC according to a certain proportion. The traceable record shall be clear and traceable.

- The qualified parts are assembled into one cylinder and then the pressure test will be done.

- Before and after assembly, the basic dimensions and workmanship will be inspected again.

- A inspection report will come into being before delivery.

No.7 Dream

*Company vision:Act as the laeder of internal hydraulic industry

*Enterprise concept:Better and stronger

*Core values:Learning and innovation,equality and justice,customers the first,and quality winning the world

*Enterprise spirit:Complete sincerity,complete precision more excellent,and up to date

*Quality policy:Pursue zero defects of our products,and realize zeo customers' complains

*Company type:Respond quickly,act immediately,finish what to do today,and improve day after day

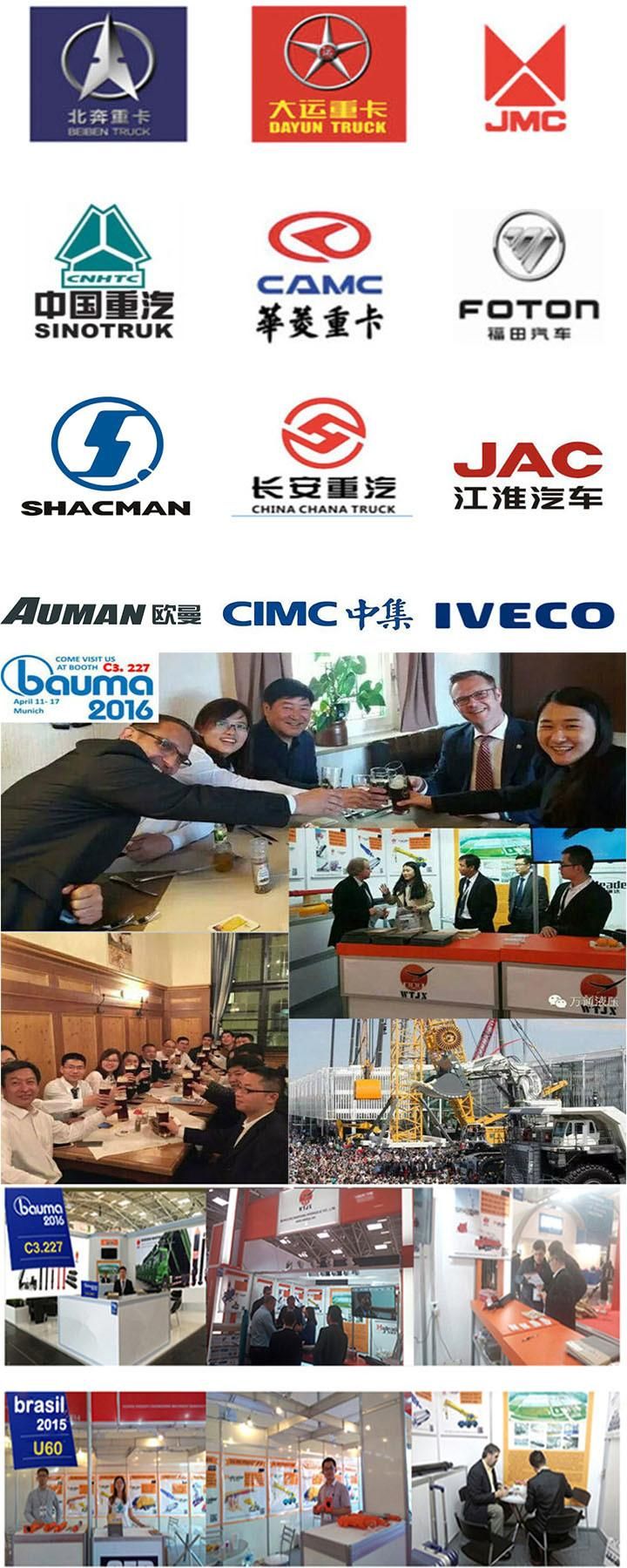

No.8 Rich Market Experiences and Exhibitions

We are the supplier of Sinotruk, CAMC, CIMC, Beiben Truck, AUMAN, JMC, FOTON, JAC, SHACMAN, Dayun, IVECO most of famous truck manufacturing and refitting company use our telescopic cylinder as first choice.

We attended each Bauma ,Las Vegas exhibition, the world grade fair for construction equipments, building material machines, mining machines and earn much more opportunity to extend our business to oversea market.

Wantong Hydraulics is a Chinese based manufacturer of engineered hydraulic cylinders for over 22 years. Our manufacturing facilities are certified to the ISO TS16949 standard. We are also an approved supplier to many large OEM equipment manufacturers in the mobile industry.

1. Every cylinder pipe material choose high quality 27 SiMn alloy seamless steel pipe, its mechanical properties are greatly improved after through the cold drawing process, equipped with the chemical composition test equipment and mechanical properties testing equipment. Through the above testing equipment to meet the requirements of the mechanical properties testing, precision is more accurate by adopting the computer digital display, for every batch of sample rate of the cold drawing pipe not less than 60%, so that can guarantee the mechanical properties of every cylinder .

2. We have our own electroplating production line to do chrome, zinc, nickel plating treatment so that the hardness and corrosion-resistance of parts can be guaranteed well.

3. Imported seals, like Parker, Hallite, NOK, etc, are usually used to extend the working life of hydraulic cylinders.

4. Excellent welding craftsmanship ensures the good durability and beautiful appearance.

5. Spray plating and automatic painting production line also make sure every cylinder looks beautiful and high-end.

No.9 FAQ

Q1. What are the same aspects of your cylinder with Hyva cylinder?

A: Same inside structure.

Same outside dimension and same mounting sizes. It can be interchangeable with Hyva's

Q2. Compared with Hyva cylinder, what are your cylinder advantages?

A: 1. Rod are chrome plated.

2. Tubes are quenched and tempered.

3. Tube inner hole goes through deephole boring machine processing. Surface roughness is 0.4Ra

and circular degree is 0.025.

4. Good quality yet lower price.

Q3: Are you a manufacture or a trade company?

A: Manufacture, we are the leader manufacturer of hydraulic industry in China with 22 years' experience and technology accumulation. With strong technical team we could solve any annoyance of you.

Q4: Do you have quality control system?

A: Yes, The quality management system introduced is: ISO/TS 16949:2009-certified by NQA and IATF cert.

Q5: How can I get a booklet and buy a cylinder from you?

A: Very easy! Just leave me a message or email or call me directly, let me know you are interesting in our products. I will talk with you for the details soon!

Q6: Can you tell me the price for the cylinder?

A: 1. Please advice the drawing with technical requirement.

2. Please advice the model No. after you check our booklet.

3. Please advice the tipping capacity, number of stages, closed length, mounting type and size.

4. Please also help advice the quantities, this is very important.

Q7: Do your products come with a warranty?

A: Yes, we have fourteen months warranty. In this year, if the quality problem we will free repair for you.

Q8: Hydraulic cylinder internal leakage?

A: 3 main reasons causing internal leakage: Overload, polishing bad controlled, cheap seal kits. As is known to all, vehicles in China are often overloaded, our products all designed to bear the overload power. Advanced equipment could assure the polish processing. And we use the imported/TOP brand seals to meet customers' requirement.

Q9: What about the quality feedback of your products?

A: We have never received even once quality complaint for many years of international business.

Q10: Can you help me to install or recommend what kind of hydraulic cylinder or power pack should I use for specific machine?

A: Yes, we have 25 experienced engineers who are always ready to help you. If you do not know what kind of hydraulic cylinders should be used in your machine, please just contact us, our engineers will design the exact products match your need.

Q11: What is the delivery time?

A: Within 15 days for samples.

15-30 days for bulk production, which is depend on quality, production process and so on.

Q12: What is your main payment term?

A: T/T, L/C, either is available.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23