Soya Nugget Production Line Soya Nugget Production Machine

Ningbo DSW International Co., Ltd. / 2022-07-05

- Power Source:Electric

- Process:Mild Processing

- Automatic Grade:Semi-Automatic

- Type:Mix Filling Machines

- Voltage:380V

- Customized:Customized

=== Base Info ===

- Model NO.:65-S

- Material:Stainless Steel

- Voltage Require:380V, 50Hz, 3phases (Adjustable

- Energy:Electricity, Oil Diesel, Gas, Steam

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Food Type:Vegetarian Meat Machine

- Need Worker:One or Two Workers for Soya Nugget Machine

- Electric Parts:LG, FUJI, Omron etc

- Delivery Detail:25 Working Days After Receiving Deposit

- Name:Soy Mince Meat Nuggets Machine

- Transport Package:Woodcase

- Trademark:Jinan Datong Machinery Company

- Origin:Jinan

- HS Code:84361000

- Production Capacity:200-250kg,H

=== Description ===

Basic Info.

Model NO. 65-S Material Stainless Steel Voltage Require 380V, 50Hz, 3phases (Adjustable Energy Electricity, Oil Diesel, Gas, Steam After-Sales Service Provided Engineers Available to Service Machinery Overseas Food Type Vegetarian Meat Machine Need Worker One or Two Workers for Soya Nugget Machine Electric Parts LG, FUJI, Omron etc Delivery Detail 25 Working Days After Receiving Deposit Name Soy Mince Meat Nuggets Machine Transport Package Woodcase Trademark Jinan Datong Machinery Company Origin Jinan HS Code 84361000 Production Capacity 200-250kg/HProduct Description

Soya Protein machine:Textured soya protein is healthy food.The finished products have high nutrition,look and taste,which like meat; easy to absorb oil, water; without cholesterol and animal fat, So It's widely used in meat products industry, fast food production, deepfreeze food production, and all kinds of vegetarian snacks and food.And The food is sliced into shapes of granules, flakes, chunks, nuggets etc.1.Flow chart: Mixing system---Extrusion system---- -Drying system---Packing system.

2.Tecnical Parameter:

| Model | Power(KW) | Capacity(KG/H) | Dimension(M) |

| SLG65-S | 90 | 200-240 | 18X1.3X2.3 |

| SLG85-S | 160 | 400-500 | 22X3.5X3.2 |

1).high speed mixerDimension(m): 1.1×0.8×1.4 Motor Power: 4KW

Speed:400rpm

Throughput: 30kg per loading (5-6 minutes per loading)

Functions: Mix powder raw material with water

Features: 1. stainless steel material(1.5mm).

2. new handle-opened design of discharge holes,no material leak

3.High speed can mix material better than other slow mixer.

2.) screw conveyorDimension(m): 3.2×0.6×0.7 Motor Power: 1.1KW

Screw speed: 300rpm

convey height range: 1.5~2.5M

barrel diameter: Φ141mm

Function:

Power material can be conveyed in the stainless steel roller to the feed machine of extruder without leaking, dust and pollution; feed quantity is even and stable.

Features: stainless steel material.

Model:SLG65-S Capacity: from 200kg/h 1. Extruder is mainly composed of feeding, pre-conditioning, extrusion and cutting systems.

2. Main engine adopts inverter to adjust speed of screw according to changing of formula.

3. adopt building block system (BBS) to be adjustable for different technology.

4. Double-shaft pre-conditioner makes excellent result of mixing and conditioning, increasing capacity of extruder 10-15%.

5. The shape and size of the textured soy protein chunk can be adjusted by the moulds.

6.Self-cleaning, when stopping, it can be cleaned without disassembling.

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

Formation of textured soy protein machine production line:

Formation of textured soy protein machine production line:1. Mixer:there are many kinds of model numbers to choose base on the production capacity.

2. Conveyor:To convey raw materials to the extruder machine

3. Extruder machine: To choose Datong SLG model extruders base on the production capacity requirement from 200kg per hour to 550kg per hour. The raw material include Low-Temperature Soybean Flakes, soybean powder, corn flour and other grains. Shape of the pellet depends on the moulds.

4. Hoister: Convey foods to the dryer, the height of the hoister depends on the dryer.

5. Multilayer dryer:Electric dryer, controlled by control box, temperature range 0-200ºC.Inside is stainless steel double layer mesh net. Drying time is adjustable according to speed. We have dryers of 3 layer 5 meter, 5 layer 5 meter, 5 layer 7 meter, 5 layer 8 meter, 7 layer 8 meter, and 5 layer 11 meter steam dryer.

6. Sifter:To remove scrap.

7. Flavoring line: To spray oil and phagostimulant, the equipment are: single roller, double roller, round roller, eight-angle roller. Varies depends on the different production line setting, to spray oil to the surface of the product and make it even. (for the TSP line it will be choosed or not according to the requirement)

8. Cooling conveyor: To lower the product temperature in order to pack it easily.

9. Sifter: To remove the wasted material and ensure quality, meanwhile to ensure the reuse of materials.

10. Packing machine: Manual and automatic packing machine.

Product Certificate

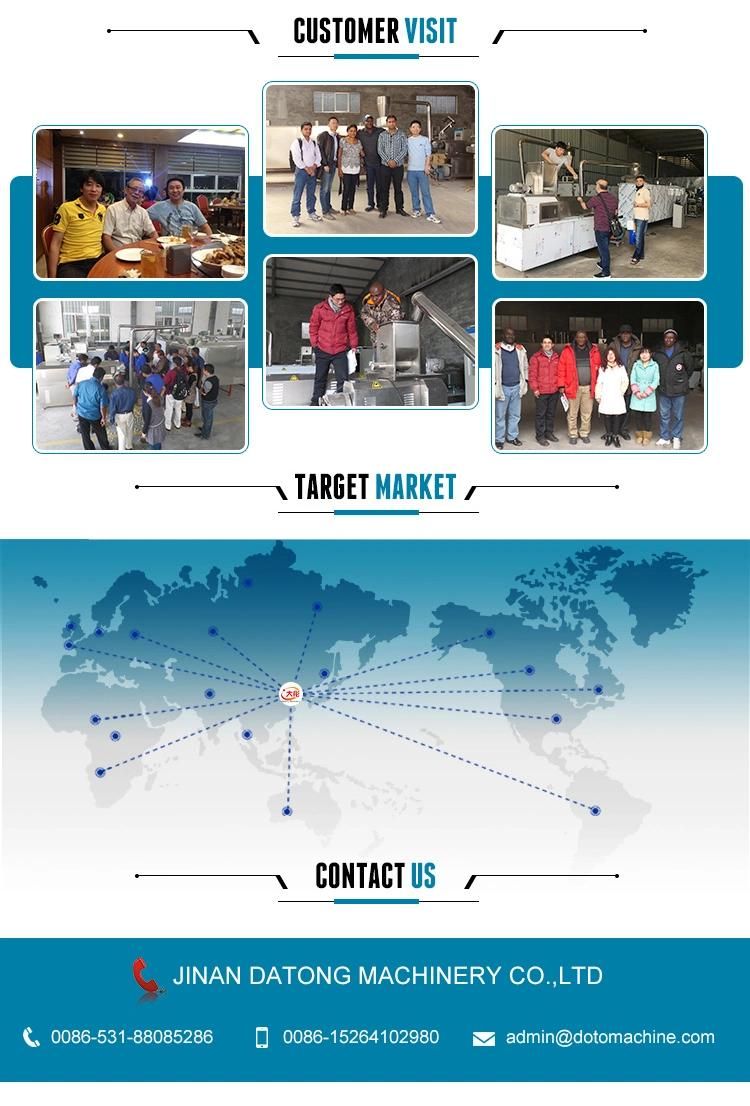

Datong Company InfoJinan Datong Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and highquality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide.

Datong Company InfoJinan Datong Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and highquality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide.  Datong Service1. Free consultation service before, during, and after sales;

Datong Service1. Free consultation service before, during, and after sales;2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

4. Overseas installation and training of equipment maintenance and operating personally;

5. Provide basic production techniques and formulas;

6. 1 year complete warranty for Extruded Food Wheat Corn Snack Pellet Making Machine.FAQ

1. Are You a manufacturer or a trading company?

We are professional manufacturer of food making machine

2. Where is your factory located?

Our factory is located in Jinan city,No.28,Gaohanji industrial park,Tianqiao Zoon,Shandong Province,China

3. What's your price of your food making machine?

Please contact us by send inquiry to us directly ,We will reply you as soon as possiable

4. How to support me,if I don't know how to use it?

Free training within the warranty period will be provided by telephone or email or skype.We also can let our technican to customer's company to provided training and support

5. If machines' wearing parts need changing ,what should we do?

We can offer wearing parts all the time ,and offer video to show how to change it.

6. What's the payment term,if we want to buy machines ?

L/C,100%T/T,Alibaba Trade Assurance,T/T30% down payment ,70%balance delivery.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23