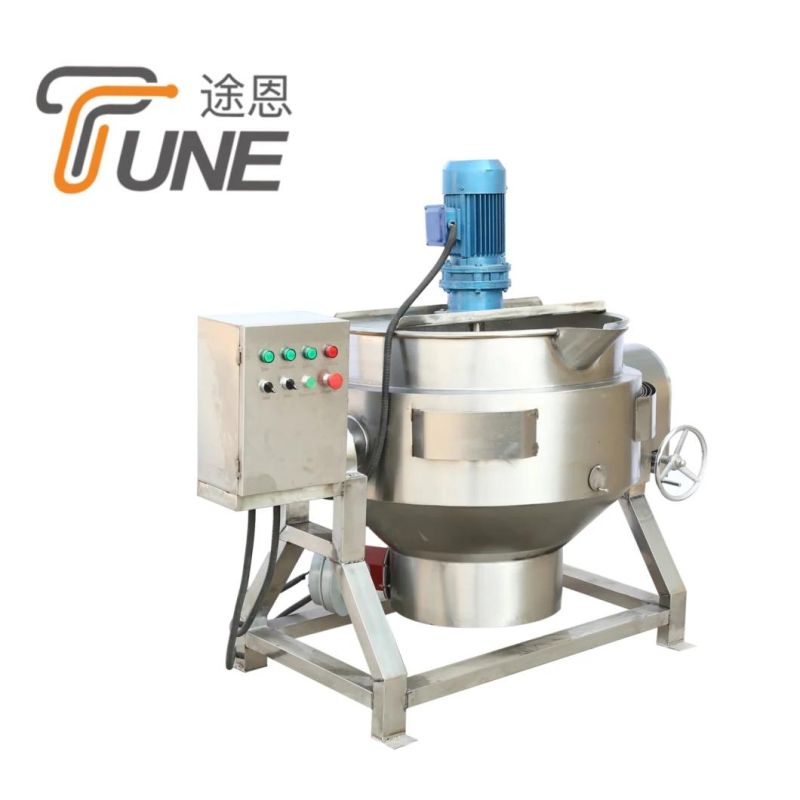

Hot Sale Electric Heating Jacketed Cooking Pot/Kettle on Sale

Fuzhou Qianxi Trading Co., Ltd. / 2022-07-05

- Type:Mixer

- Voltage:380V,220V

- Power:1.5KW

- Customized:Customized

- Bottom Outlet:38mm

- Stirring Speed:36r,Min

=== Base Info ===

- Stirring Motor Rate:1.5km

- Pot Body Material:SUS304

- Pot Body (Wall Thickness / Wall Thicknes:4mm,3mm

- Area:1470mm×1070m×1530m

- Weight (Empty Pot):180kg

- Transport Package:Whole Container Transportation

- Specification:Customized

- Trademark:TUNE

- Origin:Shandong Province, China

- HS Code:8422303090

- Production Capacity:50-800L

=== Description ===

Basic Info.

Stirring Motor Rate 1.5km Pot Body Material SUS304 Pot Body (Wall Thickness / Wall Thicknes 4mm/3mm Area 1470mm×1070m×1530m Weight (Empty Pot) 180kg Transport Package Whole Container Transportation Specification Customized Trademark TUNE Origin Shandong Province, China HS Code 8422303090 Production Capacity 50-800LProduct Description

Stainless Steel Electric Jacketed Pot/Jacketed Kettle/Jam Cooking Pot

Product Description

Product Description

High pressure cooking pot is mainly used for milk, sugar, beverage, medicine and other elements and all kinds of drugs to mix and store. It has been the indispensable equipment in making rice pudding, dairy products, beverage and pharmaceutical.

It is specially used for cooking syrup,chilli paste,and other sauce paste. It at the same time has mixing function. The machine is made of stainless steel.

Cooking pot is widely used in candy, pharmaceutical, dairy products, alcohol, pastry, candied fruit, beverage, canned foods, and other food processing, also can be used for large restaurant or dining room to boil soup, cook, stew, congee and so on. It is the ideal equipment in food processing to improve quality, shorten the time and improve working conditions.

1: pressure vessel part in accordance with national standards GB150-2011 "steel pressure vessel manufacturing standards" for the design and manufacture.

2: equipment in full compliance with GMP standards and FDA requirements, mainly in the pot of uniform distribution of heat to design and manufacture.

3: ISO9001-2000 quality assurance system, HACCP design and manufacturing requirements.

Product Specifications

| Items | Content |

| Outside/Inner diameter / volume | 880mm/550mm /0.15m3 |

| Maximum working pressure of the jacket | 0.25Mpa |

| Voltage | 380V 50Hz 3P |

| Bottom outlet | 38mm |

| Total power | 10KW |

| Stirring speed(can add speed adjustor) | 0-36r/min |

| Stirring motor rate | 0.55kw |

| Pot body material | SUS304 |

| Pot body (wall thickness / wall thickness) | 3mm |

| Size | 1100mm×900m×950m |

| Weight (empty pot) | 95Kg |

Detailed Pictures

Manual worm gear reducer mechanical structure is compact, gear wear light, long service life. With self-locking function, you can make the pot at any angle fixed, no turn pot phenomenon, safe and smooth, low noise.

Sliding bearing bearing capacity, easy assembly and disassembly. For the machine's rotation tilt, you can ensure that the machine running smoothly, no shaking phenomenon.

Equipment Characteristics

1:Jacketed pan rotation at the sealing of the overall processing, the overall plating treatment.

2: left and right shaft head with round steel processing, an increase of the strength of the shaft head.

3: the rotation of the mezzanine pot using manual worm reducer, gear wear light, long life; can be fixed in any tilt angle, no turn pot phenomenon;

4:Jacketed pan bearings using sliding bearings, the equipment running process is stable, to avoid the rolling bearing shaking situation.

Packing & Delivery

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23