Plastic PVC WPC Vinyl Panel/Plank/Tile Flooring Making Machinery Spc Flooring Making ...

Forsun Ultra-hard Material Industry Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ80/92/110 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Dimension (L*W*H) 23m*3m*3m Transport Package PE Wrapping Film, Fumigating Wooden Cases. Specification CE, SGS Trademark BOYU Origin Wuxi, Jiangsu, China HS Code 8477209000 Production Capacity 1250kg/HProduct Description

High Quality Plastic Extrusion Machine/SPC Flooring Conical Twin Screw Production LineSPC flooring stands for Stone Plastic Composite. It is the newest generation of high-quality resilient flooring. SPC flooring is an upgrade of Luxury Vinyl Tiles (LVT). No matter laying them on concrete, ceramic or existing flooring. It has a unique interlocking-edge design (advanced "click" system) for easy installation.

The main component is lime stone (calcium carbonate)+ PVC Powder + Stabilizer. Different from regular vinyl floor, there is no plasticizer inside, so it is more environmentally friendly. SPC flooring mainly structured with the UV Coating , wear resistant layer, decorative film and core board. Meanwhile IXPE option available for high end usage.

I. Basic Information:

| No. | Items | Data |

| 01 | Operation conditions | 380V/3 phases/50Hz, DC24V. |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant |

| 04 | Main material proportion | PVC: CACO3= 1:3 |

| 05 | Product specifications | Width is 1050mm;Thickness:2~9mm |

| 06 | Extrusion line mode | SJSZ110/220 conical twin screw extrusion line |

| 07 | Quality standard | Twin screw standard JB6492-2001 Electricity standard: GB5226.1-2008/IEC 60204-1:2005 |

2. Product Configuration:

3. Production Introduction:

Waterproof and Fire-retardant

The SPC Flooring is 100% waterproof and ideal for kitchens, bathrooms and basements. The fire-retardant properties causes flames to go out automatically after 5 seconds and will not produce toxic or harmful gases.

Health, Safety and Environment

Say goodbye to formaldehyde, mildew and bacteria. This product has passed the test for more than 179 different types of hazardous materials and other chemicals. Different from regular vinyl floor, there is no plasticiser inside, so it is more environmentally friendly.

Heat/Cold Resistance

SPC flooring will not curl in most temperatures or environments. SPC flooring can withstand temperature differences ranging between -75°C to 80°C. The dimensional stability is brilliant.

Quality and Strength

It is stronger than WPC floors and laminate and the price is right as well! Instead of using wood stone the SPC is used with a silica core resulting in a flooring material that is made from waterproof ingredients to begin with. SPC has 20 times the impact resistance in comparison to base laminates and 10 times the impact resistance of WPC (wood composite core) flooring. SPC flooring is stronger, more durable and more stable than regular LVT flooring. It also has an improved click-and-lock joining system. This product has superior indentation resistance (scratch and wear resistance) as well as spill and stain resistance. It has anti-abrasion properties, anti-mold or mildew properties and is slip-resistant which enables you to install it anywhere, even in combination with underfloor heating systems. It comes with five layers of protection against wear as well as IXPE, EVA and CORK underlays. These underlays are are glue free, provides acoustic benefits and a comfortable underfoot. SPC flooring is safe and easy to use, silent when walked on and warmer than any other type of vinyl product on the market.

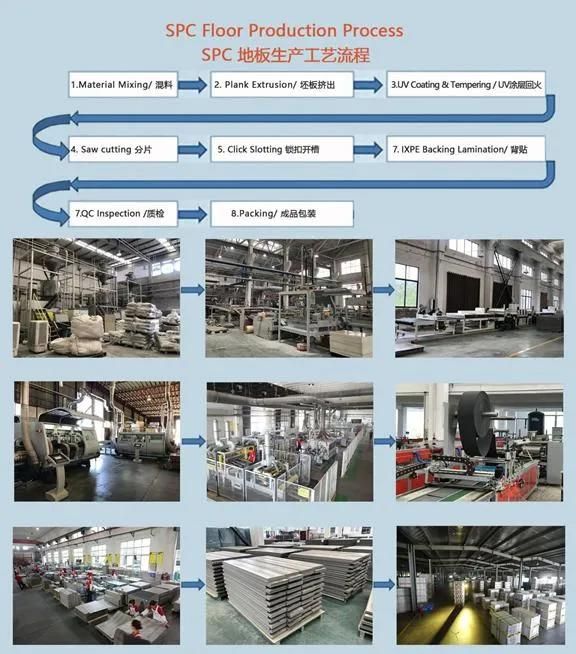

4.Production process:

The screw feeder takes the material from the silo → The Extruder Feeding Hopper → The extruder → Material Plasticizing → T-die → Calender→Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet(Optional) → Traction Machine→ Cutting Machine →Automatic Stacking Machine

5.Products Capacity:

| No. | Item | SJSZ92/188 | SJSZ110/220 | SJSZ180/360 |

| 1 | Output for 24hrs | 12~18T | 25~32T | 80~100T |

| 2 | Output sqm for 24hr | 1500sqm | 3000sqm | 9000sqm |

| 3 | Hour output | 500~700 Kg/H | 1000~1350 Kg/H | 3000~4000 Kg/H |

| 4 | Linear speed/min | 0.80~1.3m/min | 1.8~2.4m/min | 5~9m/min |

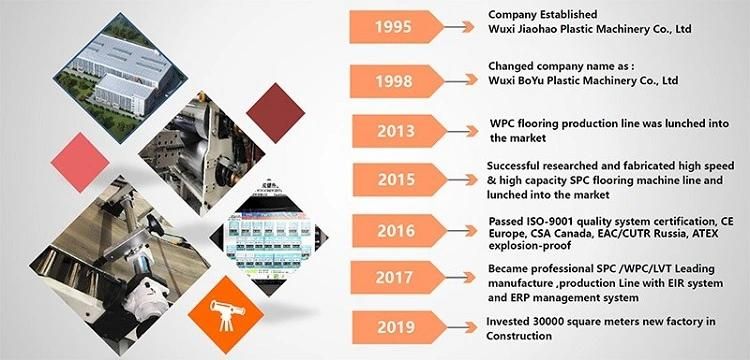

6. Boyu Company Development:

7. Why Us?

1). More than 20 years experience on plastic machinery designing and manufacturing:

Leading industry level of mechanical and electric design

Various of machine lines for optional

Provide flooring production proposal of expert level

Proposal customized as per different market demand

High Stability, performance, safety

High efficiency smart equipment, less operator needed 2). EIR(High Quality&High Depth Embossing Performance)

The word leading level EIR technology

The unique one key embossing function is effectively short operation time

Deep embossing is helpful to achieve products differentiation

Constant tension system for film unwinding

Automatic deviation rectification system for film unwinding

3). Simple and Smart Electric Control System

PLC smart control system

Profinet connection method, to ensure fast data communication and achieve remote monitoring

Adopted famous international brand of electrical elements , much more decrease the faults ratio.

Synchronous line speed control system

Anti-screw breakage, anti-blocking die, automatic stacking control system

Automatic oil/water temperature control system

8. Our Service:

1). Pre-sale service:

To provide market research information and consultation;

To provide all kinds of convenience and market service;

To help customers make project planning and systematic analysis;

To maximize customer's satisfaction.

2). After-sale service:

To install products and test products for customers;

To provide the formulas and technologies of relevant products and the information of chemical materials manufacture;

To provide technical direction according to customers' requirements;

To provide technical training for clients' employees;

To be responsible for maintenance service, door-to-door service under necessary circumstance.

3). Technology Support

Provide different products for formula and material supplier.

Production technology&Technical guidance.

Technicians dispatching for Guidance and technology exchange.

9. Shipping:

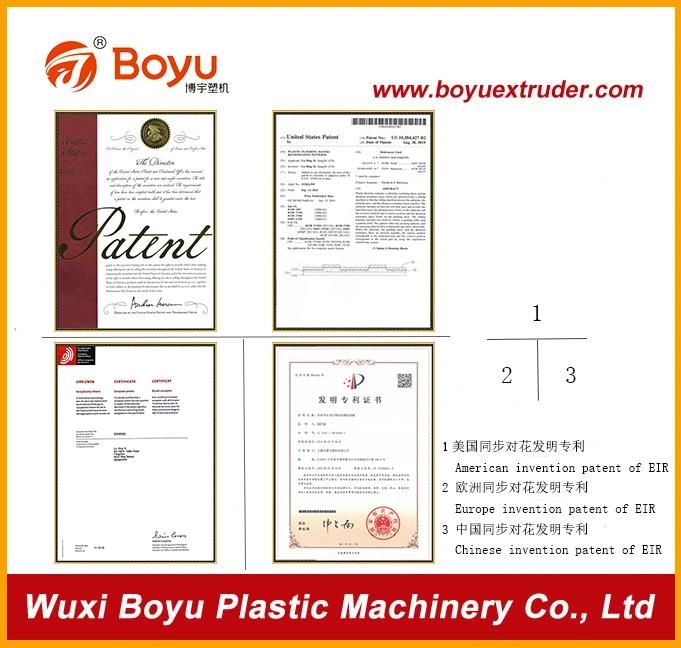

10. Certificate:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23