100mm 120mm Screw Diamater Automatic Dog Chew Pet Food Making Machine

AIRMAX AL CO., LIMITED / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

=== Base Info ===

- Voltage:220V,50Hz 380V,50Hz

- Weight:1500kg

- Warranty:2 Years

- Products Capacity:120kg,H

- Type:Pasta Machine

- Motor Brand:LG,Siemens,Chinese Brand

- Materials:Stainless Steel

- Name:Macaroni Pasta Production Machine

- Features:Long Service,High Quality Processing ,High Tec

- System Can Be Upgraded:PLC Cabinet ,Pcmobile Phone Control for Whole Line

- Production Line Name:Puffed Snacks Production Line

- Installation Support:Video or Door-to-Door Installation

- Worker Need:2-9

- Screw Diamater:100mm,120mm

- Auxiliary Equipment:Mixer,Screw Conveyor,Fryer,Dryer,Cooling Machine

- Transport Package:Wooden Case

- Specification:26000*25000*3000mm

- Trademark:Keysong

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:50et,Month

=== Description ===

Basic Info.

Voltage 220V/50Hz 380V/50Hz Weight 1500kg Warranty 2 Years Products Capacity 120kg/H Type Pasta Machine Motor Brand LG,Siemens,Chinese Brand Materials Stainless Steel Name Macaroni Pasta Production Machine Features Long Service,High Quality Processing ,High Tec System Can Be Upgraded PLC Cabinet ,Pcmobile Phone Control for Whole Line Production Line Name Puffed Snacks Production Line Installation Support Video or Door-to-Door Installation Worker Need 2-9 Screw Diamater 100mm,120mm Auxiliary Equipment Mixer,Screw Conveyor,Fryer,Dryer,Cooling Machine Transport Package Wooden Case Specification 26000*25000*3000mm Trademark Keysong Origin Shandong China HS Code 8438800000 Production Capacity 50et/MonthProduct Description

Keysong designs and manufactures more than 20 years Machinery, equipment and complete pasta

Keysong designs and manufactures more than 20 years Machinery, equipment and complete pastaproduction lines for the production of fresh pasta, dry and gluten free. Each line is designed according to the

specific plant requirements to optimize all phases of production of fresh pasta and includes automatic

mixers, extruders, sheeters, moulders, pasteurizers, dryers and coolers.

The purpose of automatic Italian pasta production lines is the production, processing and packaging of food

dough (which can be long and short) having a shelf life that generally ranges from a few weeks up to about

three months. The product is realized by means of kneading and molding, which are different depending on

the required format and the kind of pasta to be produced.

a. Raw Materials:

a. Raw Materials:This production line adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as

raw materials, potato sticks and other shapes, you can just changing of molds

b. Products:

This line can be used to produce pellets, snacks, corn flakes by adjusting the moulds from

extruder; and can be used to produce different shapes of pellets by adjusting the moulds from

extruder

c. Capacity:

15-30kg/h ,30-40kg/h,50-60kg/h,80-100/h,180-220kg/h,320-400kg/h

d.

e. Voltage:

e. Voltage:In China: Three phases: 380V/50Hz, Single phase: 220V/50Hz. We can make it according to

customers' Local voltage according to different countries.f. Machines MaterialsAll the machines are made by stainless steel, this line is with reasonable design and with high

automation; the screws are made by alloy steel, with building block system structure and self-

cleaning function

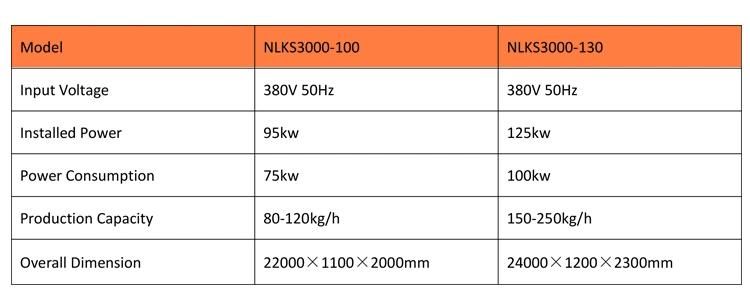

g.Technical Parameters

Our company has already exported countriesH.Our service:

1. Provide you the professional advice about the market, equipment, process, material, packing,

etc.

2. Assist you to choose equipment, design process flow, and perfect workshop layout. If needed,

we can supply service in your factory.

3. Make compensate plan to the material change according to your product, and perform the

production at site.

4. Specially design and manufacture machine, practice test, and provide relevant training as

customer required.

5. Provide reasonable packing and transportation plan, send technician to install and debug

machine and train your workers.

6. One year guaranty time, preferentially supply spare parts.

7. Design and process similar type of spare parts of import equipment.

J.FAQ

Q1. Are you a manufacturer or a trading company?

A: We are a professional manufacturer of food & feed extrusion machine.We have own factory and

R&D department. SGS has certified our company on site.

Q2. What is your payment terms?

A: Strongly recommend to use Alibaba's Trade Assurance.T/T :30% prepayment,70% before

delivery. L/C at sight is available.Other payment is negotiable.

Q3. Do you offer guarantee for the products?

A: Yes, we offer 1-2 years warranty to our products.

Q4. What about the lead time?

A: Regular products:20-30 working day/Customizable products:30-40 working days.

Q5. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.And help customer to produce new

products according to customer's formula.

Q6. What after-services do you provide?

A: Send engineers for installation, trial running and training workers at customer's site.Handling the

problems occurred during use. Supply spare and wearing parts on discount.Help customers to

solve any other problems .

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey,

Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North America { Canada }

South America { Brazil, Bolivia }

Oceania { New Zealand }

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23