Diamond Cutting Wheels for Glass Lampshade

Shaoxing Dalica Cosmetic Packaging Co., Ltd. / 2022-06-27

- Blade Type:Continuous Boundary

- Manufacturing Process:Sintered

- Application:Carbide Rod, Glass, Ceramics, Granite Cutting

- Abrasive Material:Diamond

- Bond:Metal Bond

- Cutting Condition:Dry or Wet Cutting

=== Base Info ===

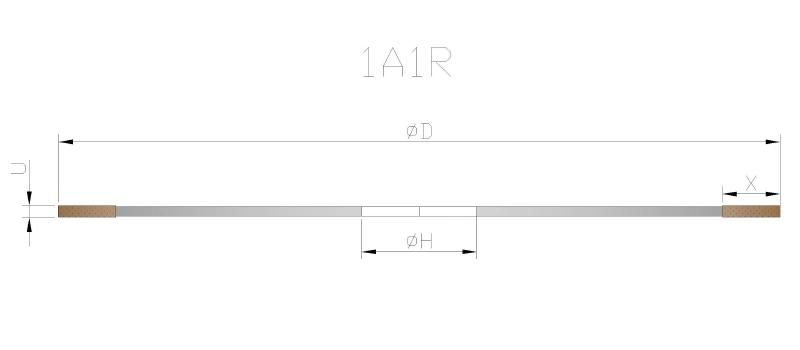

- Model NO.:1A1R

- Thickness:0.6 ~ 1.0 mm

- Grit Size:D126, D107, D91

- Transport Package:Carton Box

- Specification:150x1x31.75x10

- Trademark:BOSON Abrasives

- Origin:China

- HS Code:6804211000

- Production Capacity:3000 PCS. , Month

=== Description ===

Basic Info.

Model NO. 1A1R Thickness 0.6 ~ 1.0 mm Grit Size D126, D107, D91 Transport Package Carton Box Specification 150x1x31.75x10 Trademark BOSON Abrasives Origin China HS Code 6804211000 Production Capacity 3000 PCS. / MonthProduct Description

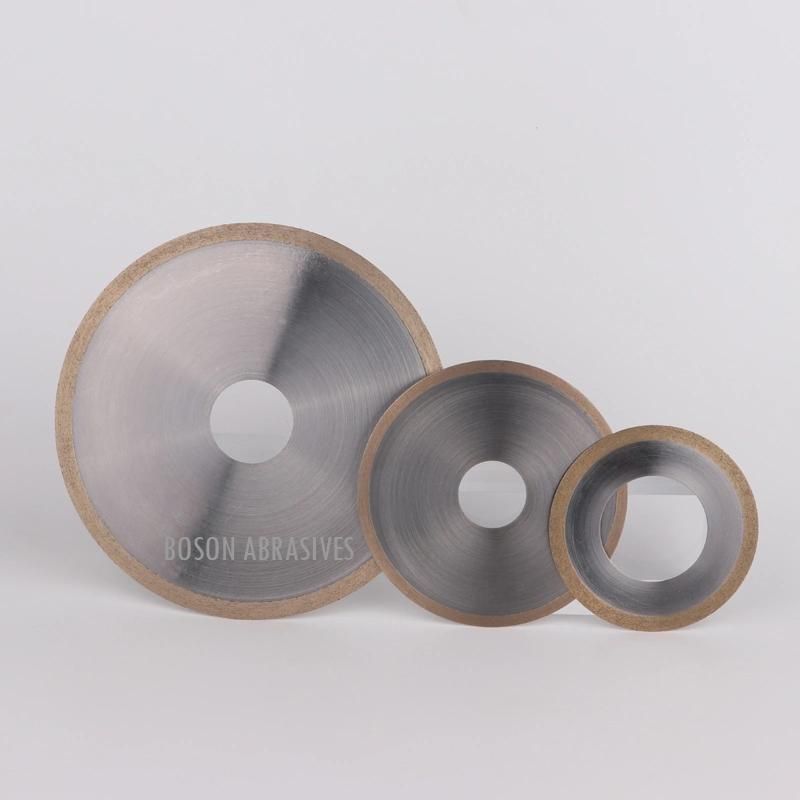

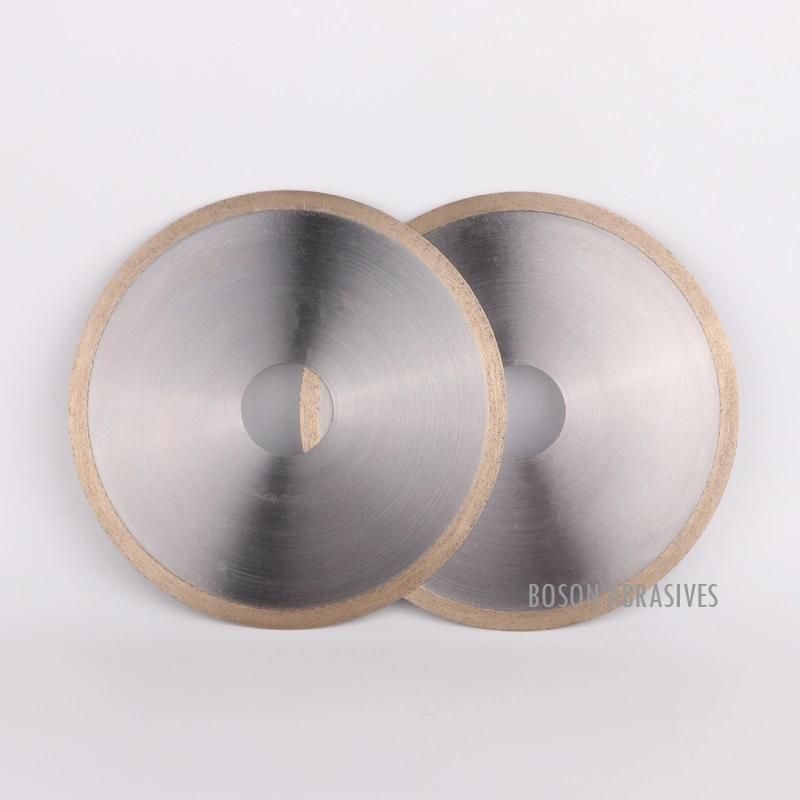

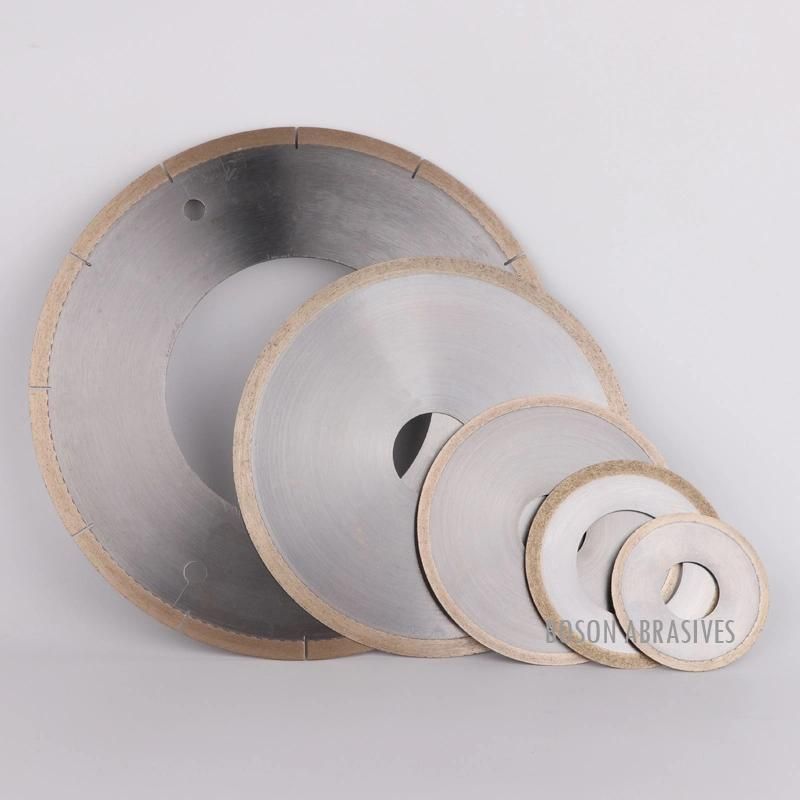

Metal Bonded Diamond Cutting Wheels for Glass Lampshade

BOSON Metal Bonded Diamond Cutting Wheels, Cutting Blade for Glass Lampshade Cutting

Application: blown, machine-pressed glass lampshade, lighting plum blossom tube, automobile lampshade, glass bell cover, glass cover, various large-diameter glass tubes cutting.

Diamond Cut-off Wheels are used for efficient cutting of hard, short-chipping and wear resistant materials such as glass, ceramics and carbide, graphite, quartz, ferrite and semiconductor materials.

CBN Cut-off Wheels are used for cutting materials with an affinity for carbon, such as iron-based alloys. High-alloy steels such as HSS and chrome steel with 12% Cr. , hardened steel from 55 HRC and magnetic materials. Soft, long-chipping materials accumulate in the chip space, so they are tend to clog. Compromises can be achieved with electroplated bonds.

Metal bond diamond cut off wheels with steel core is produced with high strength, high rigidity steel plate with sintered metal bonded abrasives layer. Compared with resin bond, the thickness is thinner with higher rigidity, suitable for deep cutting off or grooving.

The cutting wheels consist of a steel core with the cutting layer on the periphery. The cutting layer in sintered metal, resin or electroplated metal bond contains either diamond or CBN. The combination of bond, type of abrasive, concentration and grit size leads to different tool characteristics which are specified to meet the requirements of different processes and applications.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23