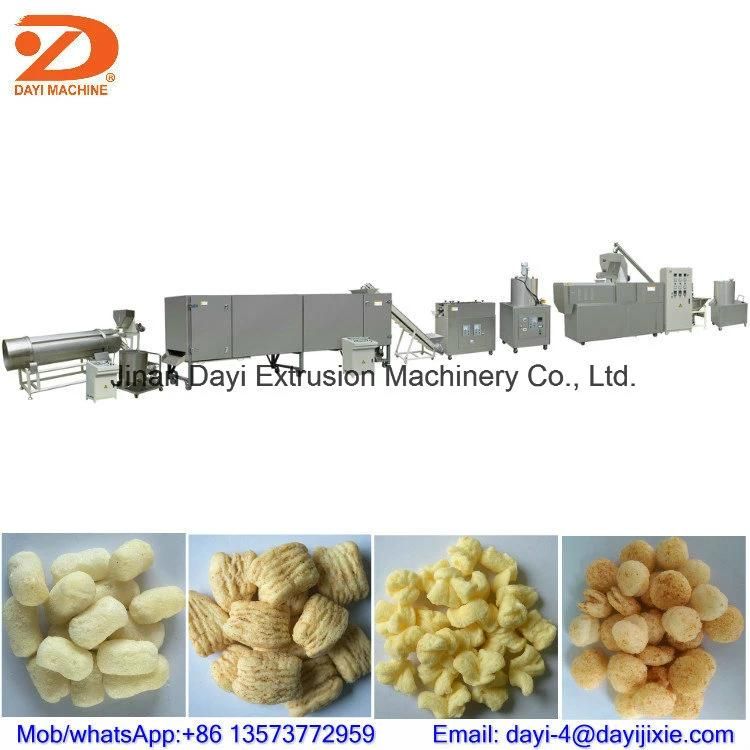

Corn Puff Food Extruder Machine for Snacks

Qingdao Albar Import And Export Trade Co., Ltd. / 2022-07-05

- Certification:CE

- Power Source:Electric

- Process:Extruding

- Automatic Grade:Automatic

- Application:Chips, Snacks

- Customized:Customized

=== Base Info ===

- Model NO.:SLG

- Material:Stainless Steel

- Capacity:150~300kg,H

- Product:Snack Food in Various Shapes

- Product Material:Corn, Rice, Soybean, Oat, Other Grains

- Component:Motor, Reducer, Gear Box, Screw, Barrel

- Produce Name:Corn Puff Food Extruder Machine for Snacks

- Transport Package:Polywood Processed Package

- Trademark:DAYI

- Origin:China

- Production Capacity:300 Pieces,Year

=== Description ===

Core-filling snack process line

Core-filling snack process line

Core-filling snack process line

Re.: The body plate and parts contacting food are all stainless steel.

All the brands of motors, inverters, and electrical elements can be adjusted as clients requirements.

Feature:

1 With adopting the latest Italy design concept to do proper improvement for the structure of screw and barrel to make sure that screw won't grind inside the barrel. This will not only extend their use life, and also avoid the grind iron scrap mixing into the material.

2 Unique design of the diversion-cone enables the uniform discharging, and pressure equalizing for the discharge point of the die.

3 The rational barrel and screw cooling structure and effective heating unit assure the accuracy of temperature control.

2. Products:

Re.: Various shapes can be made by changing moulds.

Processing line

3. Company Profile:

Since 1996, Jinan Dayi Extrusion Machinery Co., Ltd is the professional manufacturer and the leader company of extrusion food machinery. Dayi Company congregates an expert team with twenty-year experiences in this extrusion machine industry. Our double-screw extruder and single-screw extruder can produce various puffed snacks, 2d/3d pellet, textured soya protein/fiber protein, corn flakes and breakfast cereals, popcorn, cheetos/kurkure, doritos/triangle chip, fried pasta, bread crumb, hamburger patty, dog/cat/fish feed, etc.

Our machines have largely occupied the Chinese market and cooperated with many well-known food companies. Meanwhile, have been exported for nearly twenty year to almost fifty countries. such as Malaysia (Mamee), Indonesia (Pt Mayora), Philippines (URC), Vietnam (Acecook), Thailand (R&B), Japan (Nissin), South Korea (Dowul), India (Shanti, Krashi), Pakistan, Russia, Kazakhstan, Uzbekistan, Turkmenistan, Jordan, Iran, Egypt, South Africa, Algeria, the Netherlands, Poland, Macedonia, Brazil, Argentina, Australia, etc.

We can not only provide you the best machines and services, but also the best food technology and the market useful information.

Re.: Whole company is in 10000 square meters, including Sales department, Finance department, Technical department, Supply department, Factory workshop, Warehouse, After-sale department, Worker cantin.

4. Clients:

Our machines have been exported to about 50 countries and regions.

5. Packing:

Re.: Fumigation-free pallet or full package can be chosen by clients , which is suitable for long-time sea shipment.

6. All Service We Can Do for You:

--Pre-sales:

1. Free consultation about machine or process line and prompt reply;

2. Best quotation, information of machine or process line;

3. Test run machine in our factory;

4. Help arranging room and aboard for clients in our city;

--After-sales:

1. Arranging shipping matters of machines;

2. Overseas installation and debugging machines in clients' factories;

3. Training clients' workers for operating machines;

4. One year guaranty time of machines;

5. Technical support of machine and products for lifetime;

6. Supplying spare parts in best price for lifetime.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23