Mini Scale Small Capacity Industrial Fully Automatic Biscuit Produciton Line Making ...

Taizhou Huangyan Yuno Mould Co., Ltd. / 2022-07-05

- After-sales Service:Whole Lifetime

- Warranty:1 Year

- Certification:CE, ISO9001, SGS

- Power Source:Electric

- Process:Baking

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:400, 600, 800, 1000, 1200

- Application:Biscuit, Cookie

- Customized:Customized

- Materials:304 Stainless Steel

- Motors&Gearbox:Guotai

- Pneumatic Cylinder:Airtac

- PLC:Siemens

- Touch Screen Controlled System:Siemens

- Electric Components:Siemens or Scheider

- Gas Oven Burner Brand:Weishaup Brand Burners From Germany

- Conveyor Belt:PU

- Electric Oven:Hot-Wind Circulation

- Transport Package:Standard Export Wooden Case

- Specification:ISO, CE, SGS

- Trademark:Skywinbake

- Origin:Guangdong, China

- HS Code:843810

- Production Capacity:10 Set,Month

=== Description ===

Basic Info.

Model NO. 400, 600, 800, 1000, 1200 Application Biscuit, Cookie Customized Customized Materials 304 Stainless Steel Motors&Gearbox Guotai Pneumatic Cylinder Airtac PLC Siemens Touch Screen Controlled System Siemens Electric Components Siemens or Scheider Gas Oven Burner Brand Weishaup Brand Burners From Germany Conveyor Belt PU Electric Oven Hot-Wind Circulation Transport Package Standard Export Wooden Case Specification ISO, CE, SGS Trademark Skywinbake Origin Guangdong, China HS Code 843810 Production Capacity 10 Set/MonthProduct Description

Skywin Automatic Biscuits Production Line Soda Cracker Biscuit Making Machine

Dear Customers,

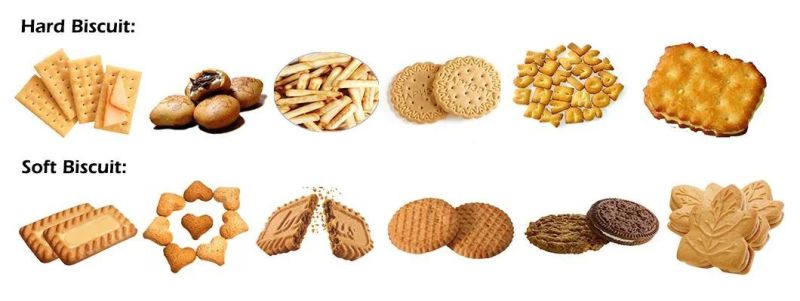

Skywin Model 400mm (or 600mm or 1000mm or 1200mm or 1500mm) Hard and Soft Biscuit Production Line is suitable for producing biscuits and cookies in all designs.

It is widely us available for making all kinds of biscuits( Hard and Soft biscuit, Soda Cracker, Cookies, also Stick biscuit, Potato chips, Print biscuit and Chocolate filling biscuit), different shape biscuit just need to change the mould, we also can design mould for you as per your details.

Product features:

1. Chinese famous brand motor & gearbox

2. SKF bearing

3. SMC Penumatic cylinder for belt tension and deflecting adjustment

4. PU and Cotton belt

5. 304 Stainless steel cover, thickness 1.5-2.0mm

6. SIEMENS transducer electric and PLC touch screen control.

7. Guarantee for 1 year along with recommended spare parts for 1 year.

The whole line is consist of:

| 1. Horizontal Dough Mixer | 5. Seperator |

| 2. Pre-sheeter | 6.Enter Stove Machine |

| 3. Gauge Roller | 7.Tunnel Oven |

| 4. Rotary Cutter/Rotary Moulder | 8.Out stove & Peeling Machine |

Horizontal Dough Mixer

We have different capacities of gauge mixers(75KGS-750KGS). You can choose it accroding to your needs.

Gauge Roller

We have the combined gauge rollers in the line, these gauge rollers will guarantee the texture of the biscuit, make the biscuit taste better.

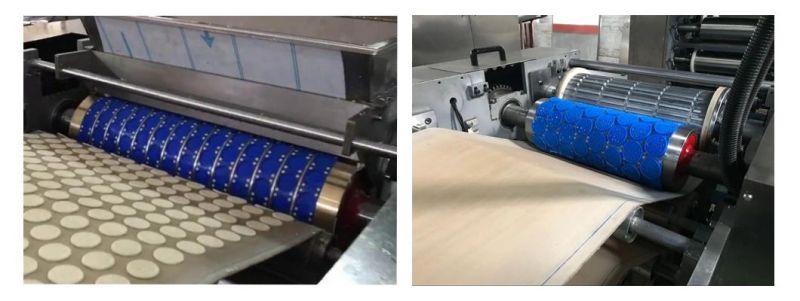

Rotary Cutter/Rotary Moulder

This biscuit forming line is for hard and soft forming, make different shape of biscuit. The dough sheet can be 1mm.

Tunnel Oven

1) There are three types of tunnel oven electric, gas and diesel oil. It depends on the natural resources of different countries.Some contries is abundant in gas.

2) Full 304 Stainless steel cover, Siemens PLC touch screen control, insolate wood cotton both side is 250mm, top 300mm and bottom is 250mm, hot air circulation system, have automatic alarm device.

3) Pneumatic automatic tracking and adjust belt and tension.

4) The size of the oven determines the biscuit capacity.

Company profile

Skywin Foodstuff Machinery Co., Ltd established in 2000, and it is a manufacturer which specialized in the fully automatic high quality Biscuit Production Line.

We provide One-stop solution and service from biscuit production to biscuit sandwiching, biscuit chocolate enrobing and biscuit packing,also we have resolved the biscuit sandwiching machines automatic connect the packaging machines and biscuit line to connect packaging machines, all operation is full automatic PLC controlled.We will supply professional consulting services for machines used within the industry of biscuit production, as well as the most suitable design proposals and qualified machines.

Our regular packaging is multilayer packing, safe transport, shipping by sea:

Step 1: Mechanical surface coated with preservative solution (to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

If any special requirements, we will pack it as requested.

FAQ

Q:Are you manufacturer?

A: Yes, we are factory specialized in Biscuit Making Machine, and have group of 30 years experienced engineers, advanced processing equipment.

Q: Why choose us?

A: We are China leading snack food machinery supplier.

Best quality & best service with competitive price.

Engineers available to service machinery overseas.

Machine has One year warranty and whole life after sales service.

Training how to install and use the machine.

Energy saving and manpower saving help you cost less.

Q: Is there a variety of language options for your operating system?

A: We use PLC controller system, it has Russian, English, Chinese, Korean, Arabic and other languages.

Q:How long is your biscuit line?

A:we can design the biscuit line according to the layout of your workshop.

Q: How can we make sure about the machine quality after we put the order?

A:Before delivery, we will send you the pictures and videos for you to check the quality, and also youcan arrange for quality checking by yourself or by your contacts in the third party inspection organization .

Pictures and videos are for reference only.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23