Soy Milk Processing Production Line Machinery

Qingdao Cobest Machinery Co., Ltd. / 2022-07-04

- Process:Thermal Processing

- Power Source:Electric

- Application:Soy Milk

- Customized:Customized

- Transport Package:Wooden Case

- Trademark:xiandai

=== Base Info ===

- Production Capacity:30sets, Per Year

- Origin:Haerbin

=== Description ===

Basic Info.

Origin Haerbin Production Capacity 30sets/ Per YearProduct Description

The production technology process and features of equipment of Semi-dry wet soymilk production

A The technics characteristic of Semi-dry wet soymilk production:

( a ) The semi-dry wet soymilk technics adopts the internationally production technology, such as soymilk pulping equipment produced by Tetra Pak.

( b )The technics characteristic of Semi-dry wet soymilk production:

1. Soybeans are dehulled after cleaned and dried to reduce the bitterness taste and remove contaminants and bacteria that adhere to the skin.

2. Soybeans do not need to be soaked.The dehulled soybeans are directly pulped after softened and inactivation. The use of a combination of the blanching method and the hot-grinding method reduces the production of beany flavor. In this process, no wastewater is discharged, which is conducive to environmental protection and reduces the cost of wastewater treatment.

3. The sterilizing and deodorizing process adopts high-temperature short-time sterilization to effectively kill the most easily-heated Thermophilic Bacillus in the soybeans and removes the odor of the beans by the vacuum flash distillation method.So it can keep the fresh of soybean milk and make the soybean milk taste better

4. The entire production line is continuously produced and the materials are in the pipeline, which reduces the secondary pollution in the production process..

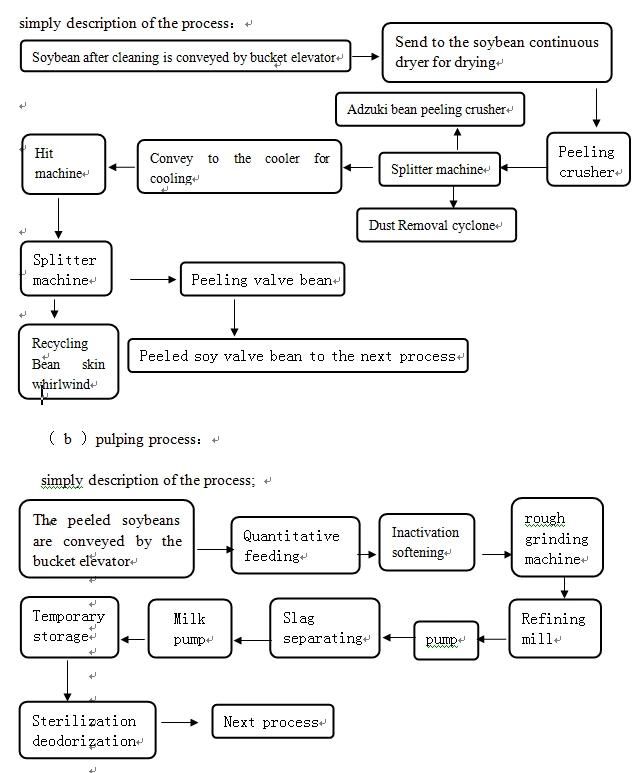

B The production technology process

( a )Soybean pre-pretreatment production process: Soybeans are cleaned, dried, cooled, removed detritus and scrap iron, and then dehulled into a dehulling machine. The dehulled soybeans are sent to the pulping section by a lifter.

The main purpose of the pre-treatment is to remove impurities and remove the skin.

According to the technical requirement the burdening and homogenizing equipment can be placed before or after sterilization and deodorization.

The dehulled raw materials feed to the quantitative feeder by the bucket elevator (the quantitative feeder can mainly adjust the conveying capacity of the material, the equipment can adjust the amount of material entering the inactivation tank by controlling the feeder to meet the ratio of water and bean technical requirements) → Convey to inactivation softening unit: Add a small amount of aqueous alkali to the dehulled soybeans (according to the alkaline water flowmeter) during steam heat treatment to inactivate most lipases. In this way, the odor of soybeans can be reduced. And soybeans softened to facilitate crushing. According to the parameters the hot water can be entered into a coarse grinding machine according to the flowmeter's instructions with soybeans (after the soybean is inactivated and softened, the hot water facilitate the dissolution of the protein. Soyabeans do not need to be soaked, not only saving energy but also safe and healthy.) After grinding, the soy milk enters the separating unit to separate slurry and slag. In order to increase the extraction ratio of soybean protein, the first separated bean dregs were added the water to the second separating.And the secondly separated slurry was used for grinding. The slurry after the first separation was transported to a temporary storage tank by a centrifugal pump,and the soybean milk was transferred from the temporary storage tank to the sterilizing and deodorizing unit. The unit is purified steam mixed directly with the material, the material is heated to 130 ~ 140 °C for 10 ~ 20 seconds and then enter the vacuum deodorizing tank to separate out the water vapor with odors.Cool the material to 90~95°C and discharge material through a plate cooler (in order to achieve the best flavor and color of soymilk, the soymilk should be quickly cooled to below 30°C.) It is sent to the ingredients program.

C The main production equipment features:

Harbin Modern Dairy Machinery Co., Ltd. focus on equipment of Semi-dry wet soymilk production. After more than 20 years of practice and research ,our company has improved some equipment and units. The performance of the entire production equipment is more reasonable and perfect.

( a )Characteristics of soybean pre-processing section equipment:

1. Soybean Continuous Dryer: This section specially configures a continuous soy dryer with high drying capability, while other domestic similar production lines use batch soy dryers or simple box dryers and fluidized bed dryers. Although the batch dryer and the simple box dryer are relatively low in cost, the disadvantage is that the soybeans are heated unevenly, which may easily result in insufficient drying of a part of the soybeans, and the other part of the soybeans has been overheated, resulting in the occurrence of charred beans and affecting the product quality. Fluidized bed dryer Soybean residence time in the equipment is too short, requiring a high intake air temperature. The continuous soybean dryer produced by our company has a large drying capacity, and a multi-layer angular shunt tube is installed in the drying cabinet to continuously divert and mix the materials when they flow. The material has a large heated area and is heated evenly. The drying effect is good and the production cost is low. With cold and hot air exchangers, it saves energy.

2. Soybean dehulling and separating equipment (Patent No.: ZL201320223568.0): The soybean dehulling and separating equipment produced by our company is suitable for supporting the production line with large amount of pulp, and has one-stage dehulling or two-stage dehulling according to different requirements of users. It is equipped with a peeling crusher, a peeling machine, and a peeling screen, so that the peeling effect is good.

3. Basic structure and characteristics of soybean dehulling and separating equipment:

The unit is composed of peeling room, hit room, bean skin separating screen surface and other parts. The soybean with the diameter of less than 10mm can be peeled and broken. After being broken, the bean skin adhered on the valve of beans in the hit room can be cleaned by blow bar, and then separating the bean skin from the unit.

After drying, the soybeans enter the peeling room. Breaking and peeling by the action of static and dynamic fluted disc.The valve of beans directly into the hit room, the valve of beans in the skin room, it is easy to clean up the skin adhere to the bean. The valve of beans and bean skin enter into the bean skin separation screen surface. The valve of beans and bean skin on the vibrating screen surface are evenly distributed into a thin layer. The bean skin is sucked away by the cyclone and the valve of beans flows out from the outlet. At this time, the peeling rate of soybeans can be more than 90%.

The unit is currently a relatively new device, designed and manufactured under the innovative ideas.

And in the production the equipment achieve design goals, increased soybean peeling rate in the production of soy milk and soybean milk.so that the quality of soy milk and soy milk powder products have been further improved.

( B )The Characteristics of pulp section equipment:

1. Accurate measurement: Due to the non-linear ratio of the rotational speed of the inclined screw conveying and the feeding amount, our company has designed a separate feeding device for the quantitative feeder, and the feeding amount required by the production process can be obtained by changing the rotation speed of the transmission.With the deactivation softening flowmeters in the deactivation softening. unit easily adjust the ratio of soybeans,water and soya and alkali water.

2. Soybean inactivation and soften equipment: The unit is include three parts, the inactivation system, the alkaline water system, and the hot water system. The stainless steel bearings are used for the inactivation system, and the quick-opening type (clamp) is used for both ends of the inactivated cylinder,easily cleaning and sterilizing. The alkaline water system is composed of two stirred low tanks and a high balance tank. The two low tanks are alternately equipped with alkali to ensure the continuity of production and the stability of the alkali water concentration. The hot water system is heated by a plate heat exchanger to ensure continuous supply of hot water. Alkaline water systems and hot water systems are equipped with flowmeters..

3. Stainless steel coarse grinding machine: The contact material part of this equipment is all made of stainless steel. The bearing part of the transmission part adopts the integral structure, which can ensure the coaxiality of the two bearing fulcrums of the drive shaft, thus ensuring the smooth running of the equipment.And it also have the characteristic of long lifetime and low maintenance. The large hollow crushing chamber can ensure the sufficiency of material crushing.

4. Refining mill machine: The pelletizing machine is used for fine grinding of materials, and the pelletizing machine uses pendulum high-speed rotation to finely grind the materials. The refining particle size is slightly coarser than that of the colloid mill, but it is beneficial to the separation of the slurry and slag. It is a professional refining equipment for the production of soybean milk and soy milk. Easy to operate and maintain.

5. The user can choose the horizontal sedimentation type slagging machine . The advantages of the slag separating machine are better than that of the vertical type, the production continuity is good, and the processing capacity is large.

6. The sterilizing and deodorizing equipment (patent number: ZL201220390580.6):

a. The sterilizer of the unit adopts the principle and structure of the isolate protein sterilizer. Steam and material are mixed in the pipeline, which is safe and reliable.

b. The unit produced by our company adds a static mixer to make the steam and material mix more evenly.

c. Steam is filtered through a titanium alloy filter to ensure the purity of the steam.

d. The feed pump uses an adjustable flow volumetric pump that can regulated flow based on production needs.

e. The use of flashed secondary steam to preheat the material saves energy.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23