Home DIY 100L 200L 300L Customized Spirits Vodka Brandy Whisky Distillation Plant

Hangzhou Panache Import and Export Co., Ltd. / 2022-07-05

- After-sales Service:Whole Life

- Warranty:12 Months

- Condition:New

- Customized:Customized

- Voltage:220V

- Composition:Water Treatment Equipment

=== Base Info ===

- Model NO.:CJ-D200

- Processing Material:Natural Ingredients

- Process:Ferment

- Function:Spirits Distillery

- Name:Spirits Vodka Brandy Whisky Distillation Plant

- Key:Home DIY 100L 200L 300L Distillation Plant

- Delivery Time:Within 35-40 Days

- Transport Package:Ocean Container

- Specification:2300*2300*12000

- Trademark:CJ or OEM ODM

- Origin:China Jinan or Others

=== Description ===

Basic Info.

Model NO. CJ-D200 Processing Material Natural Ingredients Process Ferment Function Spirits Distillery Name Spirits Vodka Brandy Whisky Distillation Plant Key Home DIY 100L 200L 300L Distillation Plant Delivery Time Within 35-40 Days Transport Package Ocean Container Specification 2300*2300*12000 Trademark CJ or OEM ODM Origin China Jinan or OthersProduct Description

Home DIY 100L 200L 300L Customized Spirits Vodka Brandy Whisky Distillation plant

| Product Name | Distillation Equipment (accept customize ) |

| Material | Stainless Steel SS304 or 316 and Copper Material |

| Grade | CE, ISO9001:2008,UL |

| Brand | CJ |

| Usage | Alcohol Making |

| Type | Volume | Component |

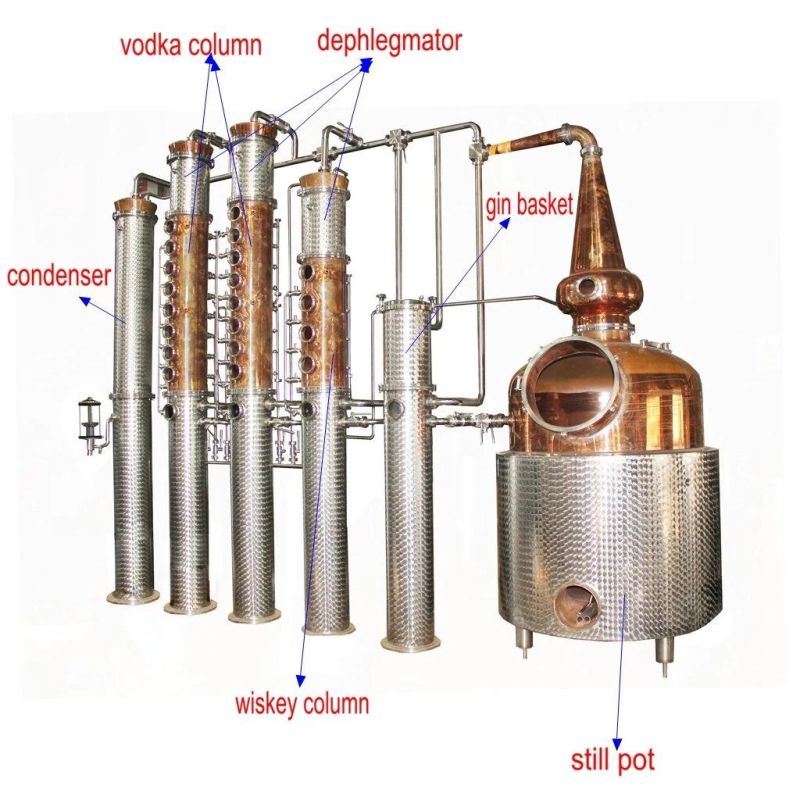

| Whisky Distiller | 50-5000L | Still pot,Swan neck,Condenser,CIP Clean,Pipe system |

| Vodka Distiller | 50-5000L | Still pot,Onion head,Column,Dephlegmater,Condenser,Pipe system |

| Brandy Distiller | 50-5000L | Still pot,Onion head,Column,Dephlegmater,Condenser,Pipe system |

| Rum Distiller | 50-5000L | Still pot,Column,Condenser,CIP,Pipe system |

| Gin Distiller | 50-5000L | Still pot,Column,Gin basket,Condenser,CIP,Pipe system |

| Multi-Function Distiller | 50-5000L | Still pot,Column,Onion head,Dephlegmater,Gin basket,Condenser,CIP, Pipe system,Collecting tank |

Alcohol Distillation Equipment Whisky Vodka Rum Gin Brandy Spirits Distillery Column Distiller

Part 1 Brief Introduction of the Spirits Distillery

Main points:

-Customized design

Variable capacity, design according to the alcohol content

-Insulated jacket

Electric heated: dimple jacket

Steam heated: stainless steel heating jacket

All around fast & efficient & uniform heating, avoid paste pot

With complete pressure control/display, ensure safety operation and real time monitoring

-Dephlegmator & Condenser & fractional condenser

Shell-and tube condenser, efficient cooling for spirit vapor

-Electronic stirring device

Uniform heating, liquid rolling to accelerate distillation process

-Material

Food&sanitary copper/stainless steel, smooth and shining

Part 2 Package & Shipment

Packages:

1. LCL: Plastic film and bubble film, fumigation free wooden case

2. FCL: Plastic fim and bubble film, iron frame if needed, necessary fixation

Suitable for shipping, up to export standard

Shipping:

Delivery to main port

Part 3. Relative product

Turnkey Distillery Solution:

-Malt Mill

-Mashing kettle

-Fermenter Fermentation tank / fermenter

-Liquor storage tanks

Turnkey Spirit Solution:

-Variable Wine Fermentation/storage tanks

-Complete Winery solution

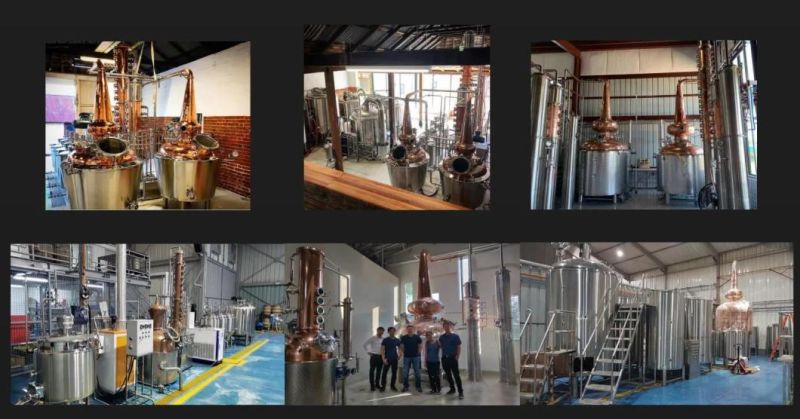

Part 4 Our Service

-Free consultation for your project, finalize best solution within your budget

-Equipment arrangement design with technical drawings and layout

-Handle the shipment from workshop to specified port with safety and solid package

-Engineer going abroad for installation, debugging and personal operation training

-Provide 3 years complete guarantee for main parts, and life-long maintenance and after-sales service

-Customized production, OEM production acceptable

The whisky brewing process can be divided into the following seven steps:

1. Sprouting (Malting)

Firstly, the malt or grain after the impurities are removed is soaked in hot water to germinate. The time required during this period varies depending on the variety of the wheat or grain, but generally it takes about one week. It takes two weeks to start the germination process. After it germinates, it is dried or peat is used to fumigate it. After cooling, it will be stored for about one month. The germination process is considered complete. It is particularly worth mentioning here that, among all the whiskeys, only the whiskey produced in Scotland uses peat to dry the malted wheat or grains, so it gives Scotch a unique flavor. That is, the smoky taste of peat, which is a feature that other types of whiskey do not have.

2.Mashing

Put the germinated wheat or grains stored for one month in a special stainless steel tank, mash them and cook them into juice. The time required during this period is about 8 to 12 hours. Usually, during the grinding process, the temperature and Time control can be said to be a very important link, too high temperature or too long time will affect the quality of wort (or cereal juice).

3. Fermentation

The cooled wort is added to the yeast for the fermentation process. Because the yeast can convert the sugar in the wort into alcohol, after the fermentation process is completed, a liquid with an alcohol concentration of about 5% to 6% will be produced. Call it "Wash" or "Beer". Since there are many types of yeast and their influence on the fermentation process is not the same, different whiskey brands regard the types and quantities of yeast they use as their trade secrets. It is not easy to tell outsiders that in the process of fermentation, whiskey factories will generally use at least two or more different types of yeast for fermentation, but at most a dozen different types of yeast are mixed together for fermentation. effect.

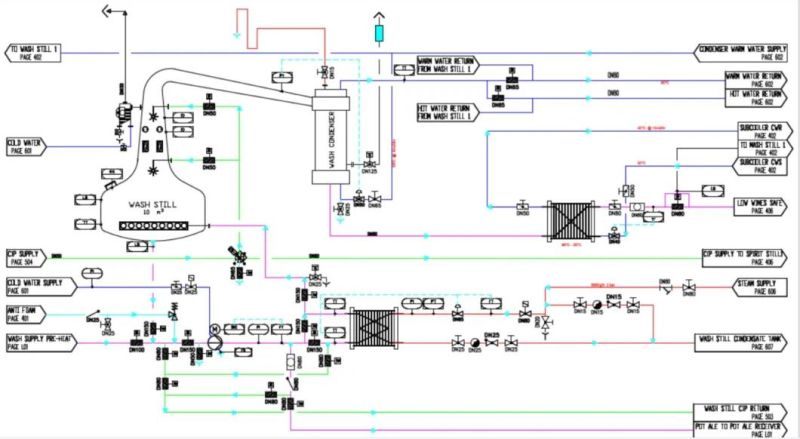

4. Distillation

Generally speaking, distillation has the effect of concentration. Therefore, after the low-alcohol "Beer" formed by the fermentation of wheat or cereals, it needs to go through a distillation step to form whiskey. At this time, the whisky alcohol concentration is about 60%. Between ~70%, it is called "new wine". The distillation method used for wheat and cereal raw materials is different. The malt whiskey made from wheat adopts a single distillation method, that is, the second distillation is carried out in a single distillation container. Distillation process, and after the second distillation, the condensed out of the wine is removed from the head and tail, and only the "Heart" part in the middle is taken to become a new whiskey wine. In addition, the whiskey made from cereals adopts a continuous distillation method, using two distillation vessels in series to carry out a two-stage distillation process at a time. Basically, each winery screens the amount of "wine core". , There is no fixed and unified ratio standard. It is completely determined by each winery's wine requirements. Generally, the ratio of wine cores taken by each winery is mostly between 60% and 70%, and some wineries are To produce high-quality whiskey, use the purest part. For example, the world-famous Macallan single malt whisky is the case, that is, only 17% of the "wine heart" is used as the new wine for brewing whiskey.

5.Maturing

The distilled new wine must go through an aging process, so that it can be aged in oak barrels to absorb the natural aroma of plants and produce a beautiful amber color. At the same time, it can gradually reduce the strong stimulation of its high concentration of alcohol. At present, there are relevant laws and regulations in Scotland to regulate the aging time of wine, that is, the age of each wine must be true and correct. Scotch whisky must be brewed in wooden barrels for at least three years. To go on sale. With such strict measures and regulations, on the one hand, the rights of consumers can be protected, and the replacement of whisky produced in Scotland has established a high-quality image in the world.

6. Blending

Due to the large variety of wheat and cereal raw materials, the whisky produced also has different flavors. At this time, it depends on the different experience of the bartenders of each distillery and the requirements of the brand's wine quality. , According to a certain proportion of the blending and blending of their own unique taste of whiskey, so the blending process and content of each brand are regarded as absolute secrets, and the quality of the blended whisky is good or bad. It is entirely up to wine experts and consumers to judge. It should be noted that the "mixing" mentioned here includes two meanings, namely the mixing of cereal and barley raw wine; the blending of raw wines of different ages.

7. Bottling

After the blending process is completed, the last thing left is bottling, but before bottling, the blended whiskey must be filtered again to remove its impurities, and then the automatic bottling machine can be used. Divide the whiskey into each bottle according to a fixed volume, and then paste the brand of the respective manufacturer and then pack it for sale

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23