Starch Sweetener Glucose Fructose Maltose Syrup Machine, Corn Wheat Starch Grain Deep ...

Guangzhou Qiandelu Technology Co., Ltd. / 2022-07-04

- After-sales Service:Spare Parts, Field Service

- Type:Starch Sweetener Complete Machine

- Application:All

- Voltage:380V

- Press Materials:Corn

- Condition:New

=== Base Info ===

- Model NO.:myande

- Customized:Customized

- Brand:Myande

- Capacity:100-1000t,D

- Raw Material:Starch

- Delivery Time:6 Months

- Installation Time:6 Months

- Warranty Period:One Year

- Worker Qty:3-5 Persons Per Shift

- After-Sales Service Provided:Engineers Service Machinery Overseas

- More Information:Design by Customer′s Requirements

- Transport Package:Container

- Specification:ISO

- Trademark:Myande

- Origin:Yangzhou, Jiangsu

- Production Capacity:200units,Year

=== Description ===

Basic Info.

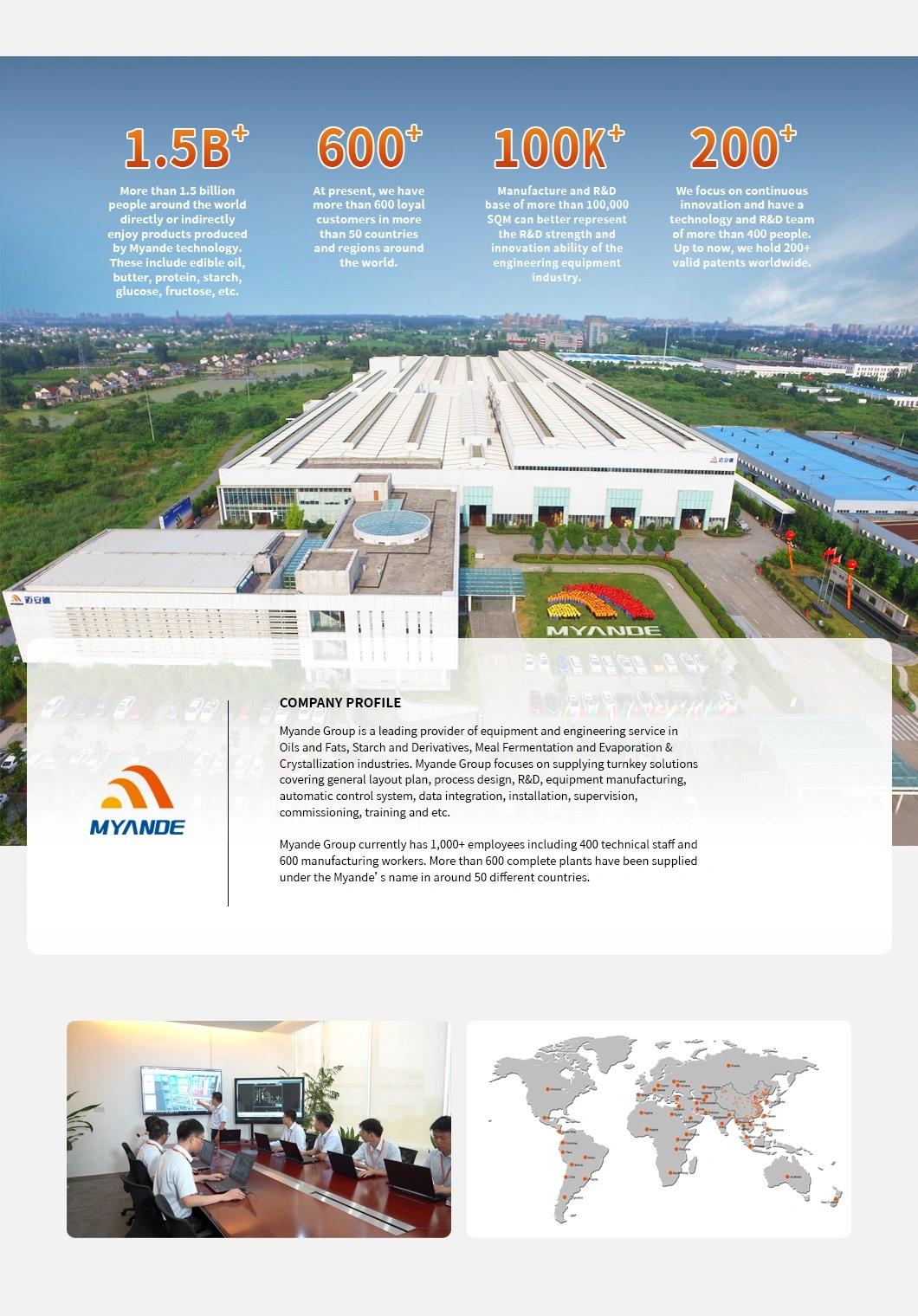

Model NO. myande Customized Customized Brand Myande Capacity 100-1000t/D Raw Material Starch Delivery Time 6 Months Installation Time 6 Months Warranty Period One Year Worker Qty 3-5 Persons Per Shift After-Sales Service Provided Engineers Service Machinery Overseas More Information Design by Customer′s Requirements Transport Package Container Specification ISO Trademark Myande Origin Yangzhou, Jiangsu Production Capacity 200units/YearProduct Description

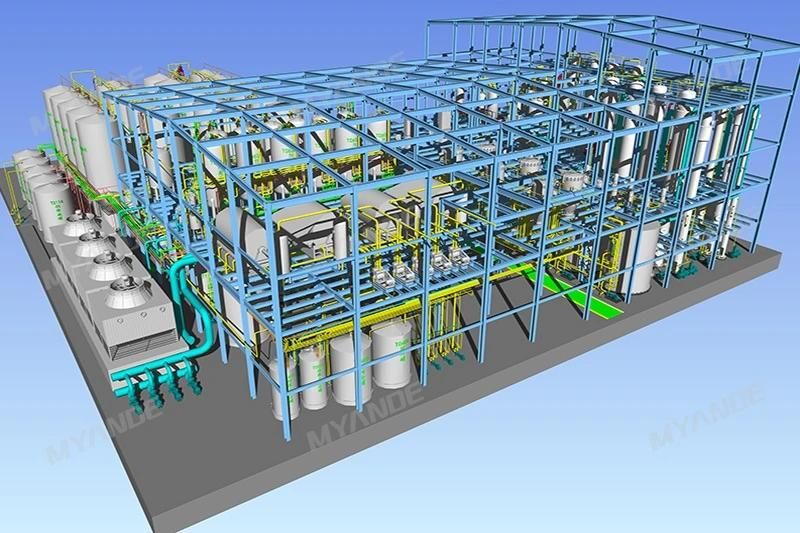

Starch Sweetener Fructose Glucose Maltose Syrup MachineTurnkey Factory Supplier

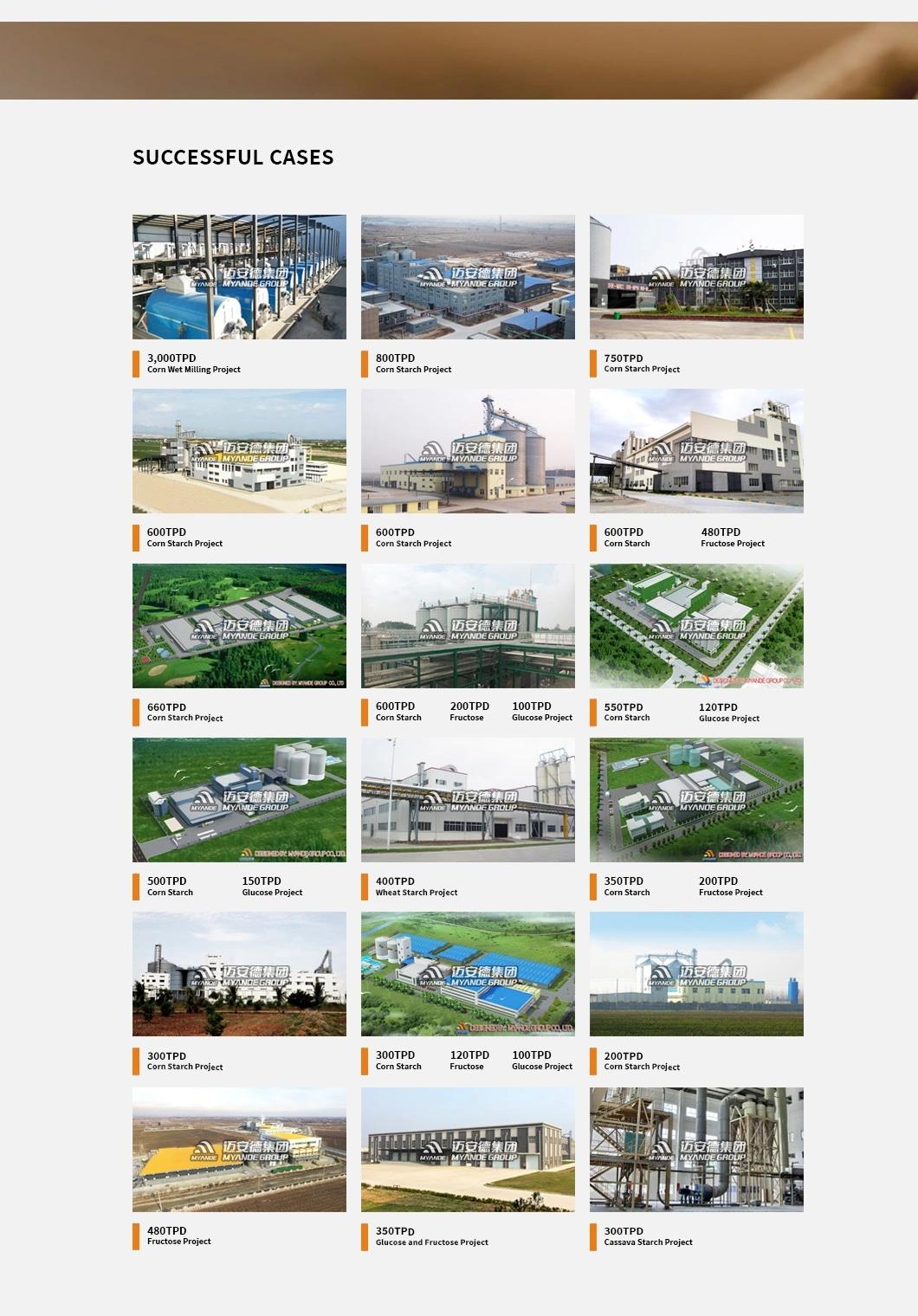

1. Starch Milk Liquefaction

One-stage jet cook liquefaction is designed under the temperature of 105ºC. After liquefaction, the DE value is 12-18, with clear appearance and good protein flocculent condition.

2. Saccharification

Liquefied starch milk will be in the reaction under the saccharification enzyme.

3. Protein Filtration

After saccharification, the material enters into belt vacuum filter to remove protein residues, which can be used as animal feed.

4. Decoloration

This section is designed to remove remaining residues such as colloid particles, tiny amount of starch, bacteria and other impurities etc from syrup to obtain clear liquid, which is to increase the purity and transmittance of syrup.

5. Ion Exchange

Ion exchange resin is used for removing the mineral from syrup, the syrup will be passed through cation-anion-cation-anion. The purpose of ion exchange is to reduce calcium content and ensure the bleaching performance. The resin can be regenerated by sodium hydroxide and hydrochloric acid.

The ion exchange system consists of three parts, which is DE96 glucose syrup ion exchange, F42 syrup ion exchange and F55 syrup mixed bed ion exchange. DE96 glucose ion exchange and F42 ion exchange adopt counter-current full chamber bed technology. F55 sugar adopts mixed bed technology. Full chamber bed is a single-room or multi-room vessel with over.

6. Evaporation

DE96 glucose is concentrated to 45% DS by using falling film evaporator. It will use the secondary flash steam from liquefaction ejection.

7. Isomerization

Using immobilized glucose isomerase to convert glucose to F42 fructose. To ensure the activity of isomerase

enzyme, proper temperature and pH value shall be maintained by adding MgSO4 and Na2S2O5.

8. Concentration

After the isomerization of F42 fructose, multiple-effect falling film evaporator is used to evaporate the syrup to concentration 60%, and then go to chromatographic separation.

9. Chromatographic Separation

SSMB chromatography separation technology is used separation the glucose and fructose because of the two compositions have different migration rate.

10. Deodorization

After ion exchange fructose passes through decolourization and deodorization by active carbon, which is to remove the organic impurities and improve the light transmittance. High efficiency closed plate filter is designed with full automation for easy operation.

11. Concentration

In this section, fructose concentration is concentrated to 77% through falling film evaporator.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23