China Best Quality Huatai New Design Palm Kernel Oil Extraction Machine Plant From Fruits

Shenzhen Xiangfeizhu Technology Co., Ltd. / 2022-07-05

- Type:Refining Plant

- Application:Palm Fruits

- Voltage:380V

- Appearance:Horizontal

- Press Materials:Palm Fruits

- Press Series:First Class

=== Base Info ===

- Model NO.:Huatai 50-1000T,D

- Condition:New

- Customized:Customized

- Oil Yield:50-1500t,D

- Oil Color:Transparent

- Staff Training:Free

- Warrantity Period:12 Months

- Oil Grade:1, 2, 3, 4, Grade According to Your Need

- After-Sale Sevice:Engineer Available to Service Machine Overseas

- Patent:Yes, 22 Patents Certification

- Certifications:CE, SGS, ISO9001, BV, etc

- Usage:Used to Refine The Crude Palm Oil

- Transport Package:Nude Packing, Transportated in Container

- Specification:According to different specifications

- Trademark:HUATAI

- Origin:Henan, China

- HS Code:847920000

- Production Capacity:20 Sets,Month

=== Description ===

Basic Info.

Model NO. Huatai 50-1000T/D Condition New Customized Customized Oil Yield 50-1500t/D Oil Color Transparent Staff Training Free Warrantity Period 12 Months Oil Grade 1, 2, 3, 4, Grade According to Your Need After-Sale Sevice Engineer Available to Service Machine Overseas Patent Yes, 22 Patents Certification Certifications CE, SGS, ISO9001, BV, etc Usage Used to Refine The Crude Palm Oil Transport Package Nude Packing, Transportated in Container Specification According to different specifications Trademark HUATAI Origin Henan, China HS Code 847920000 Production Capacity 20 Sets/MonthProduct Description

Henan Huatai Food & Oil Machinery Engineering Co., Ltd, - International Leading Manufacturing Expert of Grain and Oil MachinesFounded in 1953, Henan Huatai Food & Oil Machinery Engineering Co., Ltd. Is a large-scale and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress, extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.

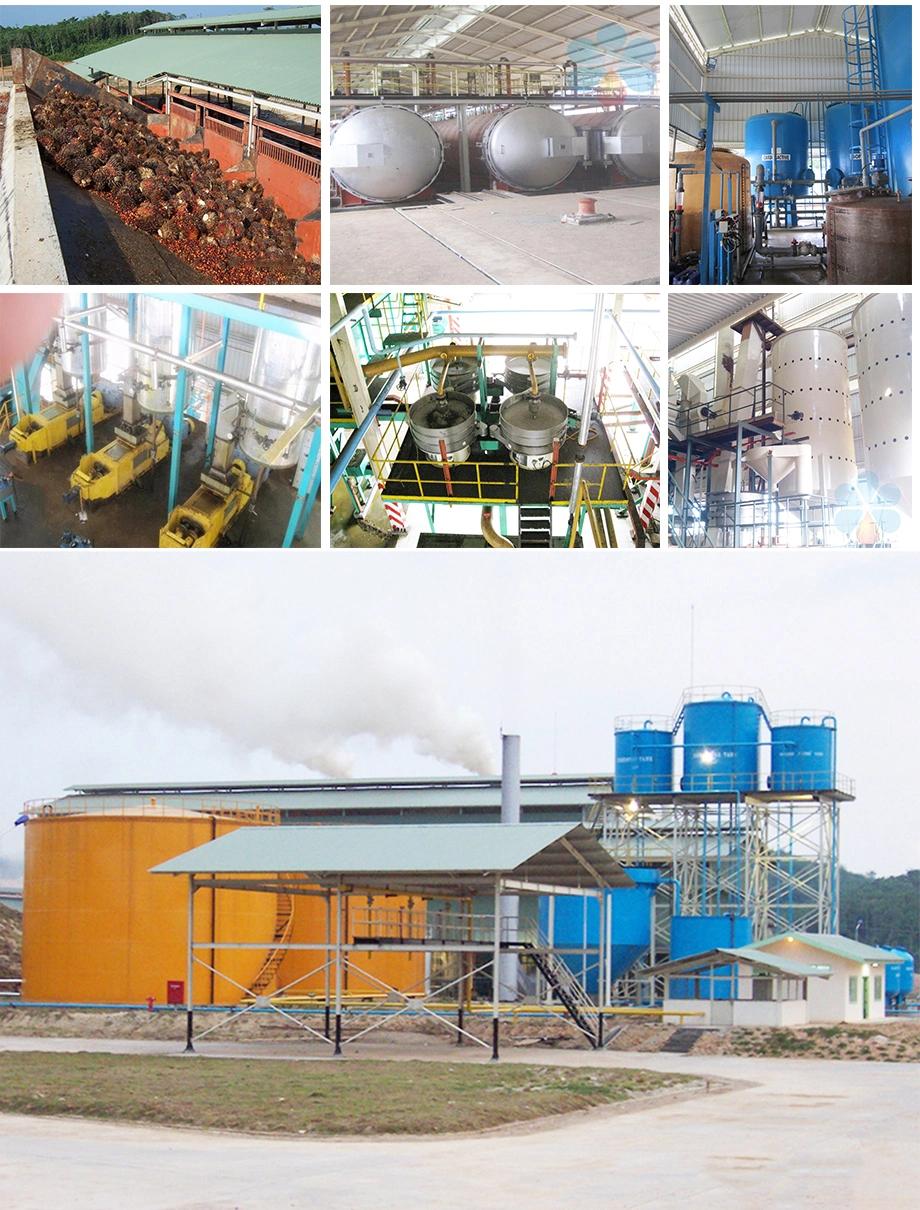

Palm Oil/Palm Kernel Oil Pressing Machine

1. Main Introduction of the edible palm kernel oil pressing machine

1) Equipped with automatic temperature rising and oil-cleaning system

2) Both cold press and hot press

3) The design of the expeller press is novel and performance is perfect

4) It requires low investment and generates high profit, machine covers small space, performs perfectly, and it is easy-to-operate

5) Suitable for those who do business in the country market or who runs a small- scale oil mill

6) People could see the whole process of oil extraction, it's clean and reliable

7) These include motor, vacuum, filter, heater and electric control cabinet

8) The assistant part can help the oil presses with higher output

9) The function of the vacuum oil filter used to filtrate the crude oil which come out from oil press

10) They are an ideal choice for customers

2. General processing description of palm oil and palm kernel pressing factory

Raw material- Cleaning -Crushing-Roast-Pressing-Filter-Crude Oil-Refining -edible oil

1) Ready the seeds

2) Adjusting the machine, such as, electricity, heating (if cold pressing, do not open heating)

3) Opening up the machine, putting seeds into the feeder,

4) Seeds into the screw bolt, beginning of pressing

5) The crude oil is out of the squeezing bolt, then flowing into the board,

6) Then into the vacuum filter, using it for filtration

7) After filtration, the oil is out of the bottom of pipe

Main spares of palm kernel oil pressing machine:

Squeezing bar/Squeezing head/Squeezing bolt/Squeezing screw/ Ring/ Cake outlet/Vacuum filter

3. The main advantage of palm kernel oil pressing machine

Our company has applied the automatic control system with advancement, security, reliability into the pretreatment, extraction, refining and fractionation in large oil plants. For its application in automatic control system, it can control the production in the entire workshop and monitor the operational status of each device by controlling the computer terminals in the room. One person only can operate the entire workshop, with efficient production management. It has greatly reduced the production cost and improved the management efficiency.

1) Using vacuum filter, it is able to simply filter the crude oil after pressing

2) It is able to save labour, about 60%. One or two person is needed per machine

3) Protecting the environment, comparing with the traditional oil press machine, it is about to meet the standard of green environment.

4) Low investment, more profit

Note: If you have any questions about the palm oil refinery plant, you can just feel free to ask us. All of our teams will try our best to offer most suitable solutions for you.

| Meal Residue | ≤1% |

| Solvent residue in leaching meal | <600PPM |

| Solvent residue in leaching oil | <300PPM |

| Solvent Consumption | ≤3-4Kg/T |

| Power Consumption | ≤12Kwh/T |

| Steam Consumption | ≤320 Kg/T(6kgf/cm²) |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23