3000L 30bbl Stainless Steel Beer Fermenter Tank for Brewery

Jinan Jotop Import and Export Trade Co., Ltd. / 2022-07-05

- Processing Material:Natural Ingredients, Water Malt Yeast Hops

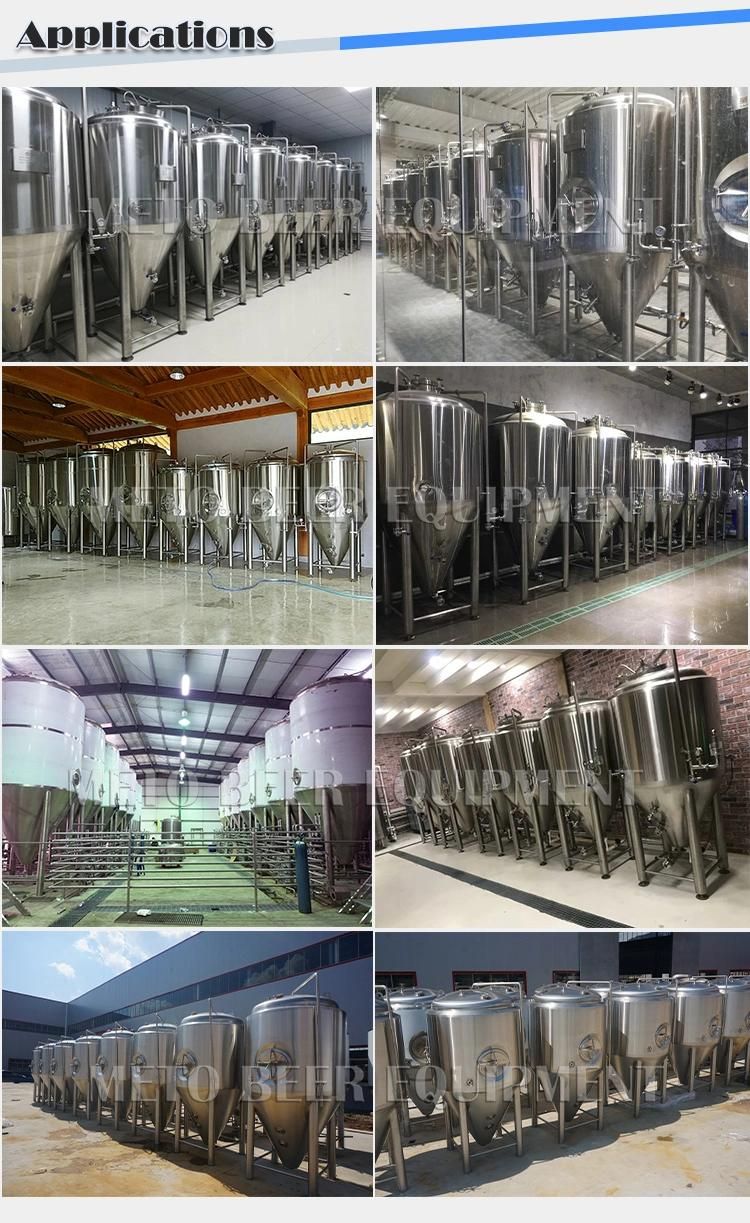

- Application:Beer, Cerveza, Beer Brewing, Brasserie

- Customized:Customized

- Certification:CE, UL, ISO9001

- Power Source:Steam , Electric , Fire

- Automatic Grade:Semi-Automatic

=== Base Info ===

- Model NO.:MT-3000L FT

- Condition:New

- Voltage:220V, 380V

- Material:Full Stainless Steel SUS304

- Welding:Arc Argon Protection

- Warranty:3 Years for Tank

- After Sales Service:Installation and Equipment Commission

- Technology:Offer Auto CAD and 3D Design Drawing

- Material Thickness:Inner Wallet 3mm Outer Wallet 2mm

- Fermenter:Double Wallet with Dimple Cooling Jacket

- Cooling Unit:Chiller with Glycol Tank

- Control Unit:Temp. Controller, HMI , PLC or Touching Screen

- Insulation:Polyurethane Foam

- Polish Finish:0.4-0.6um

- Surface Finish:Brushed , Mirror , Pickled SUS304 or Copper

- Product Name:Fermenter Tank

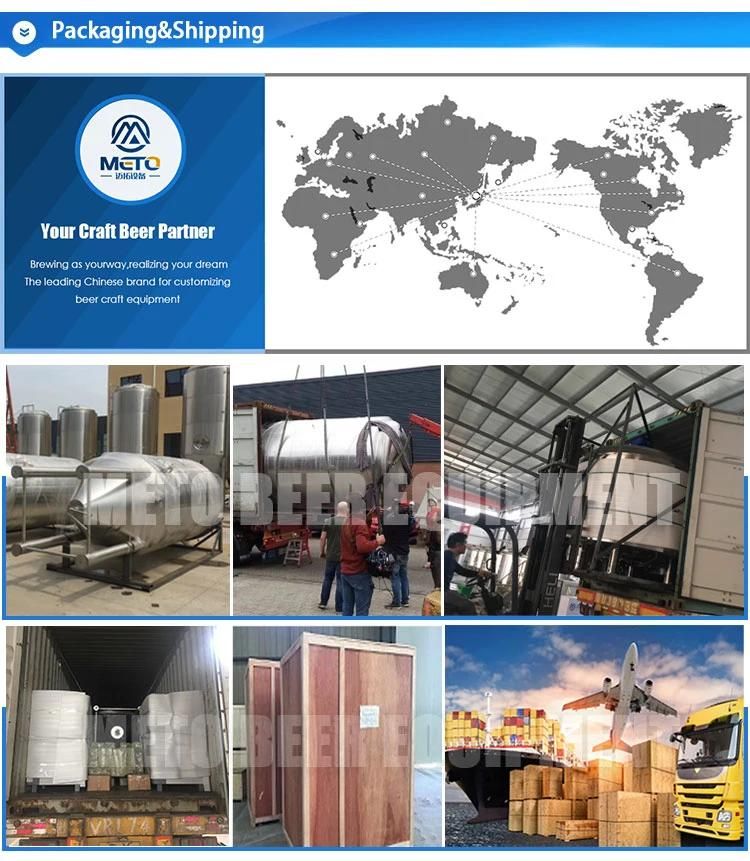

- Transport Package:Plywood Case by LCL or Container by FCL

- Specification:Customized

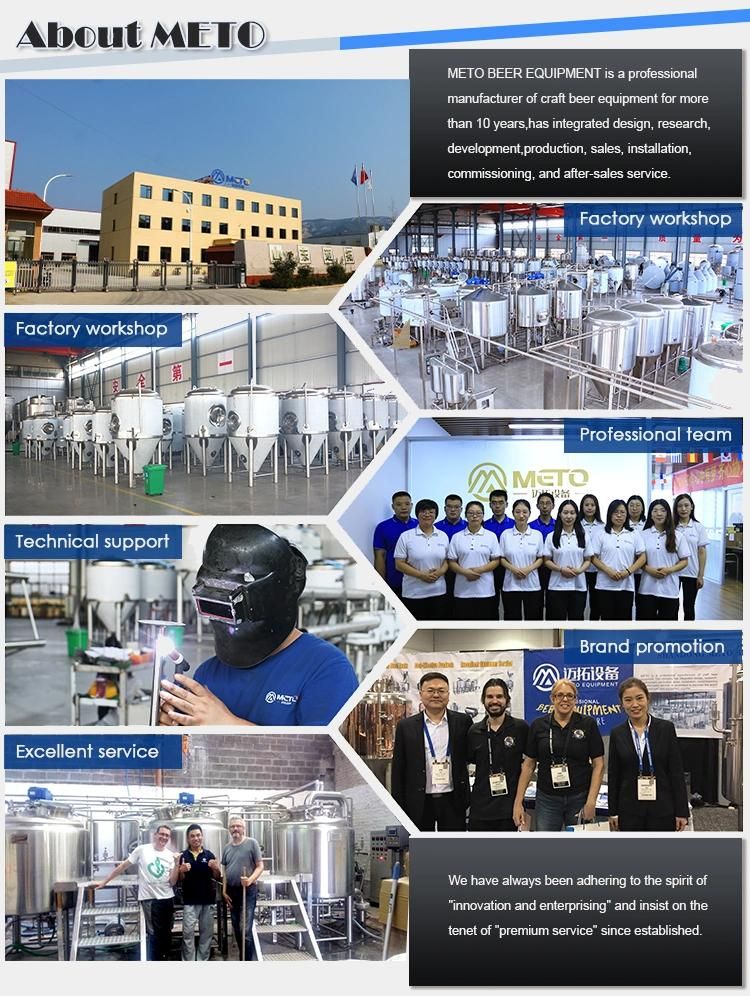

- Trademark:METO

- Origin:Jinan, China

- HS Code:8438400000

- Production Capacity:20 Sets Per Month

=== Description ===

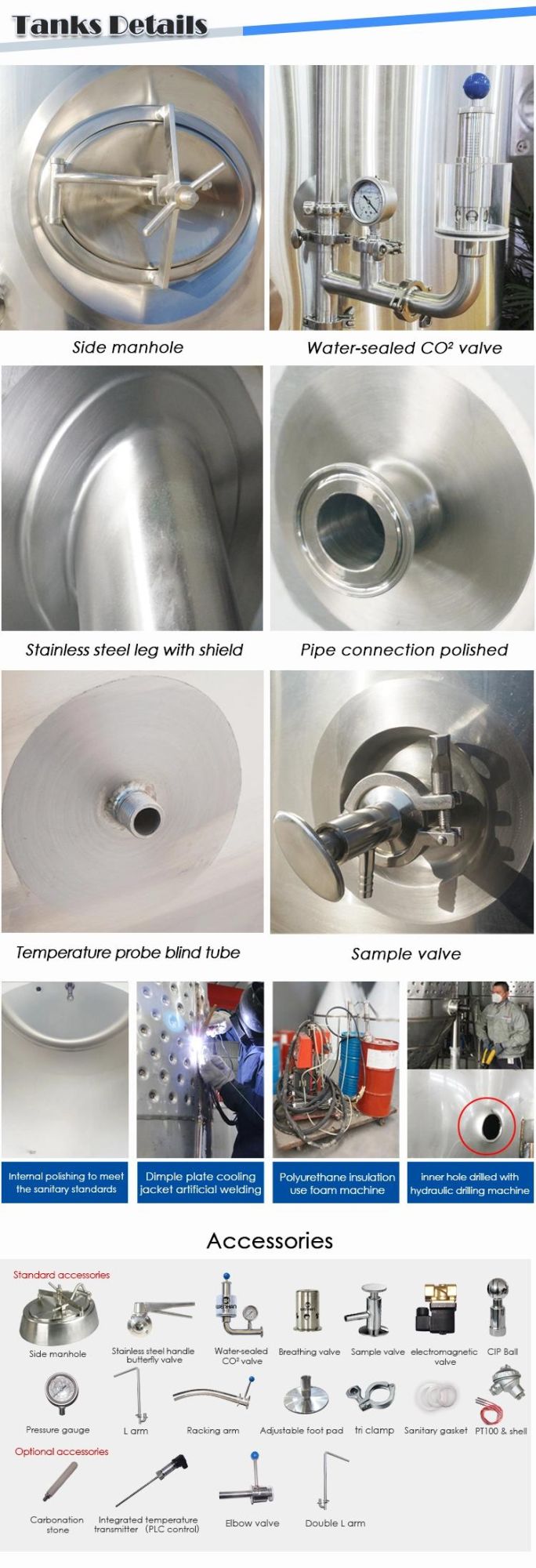

Beer Fermenter

Exterior Shell: 2mm/3mm, can be customized

Equip with Electromagnetic valve;

Shockproof pressure gauge on CIP arm;

Safety valve on fermenter top;

Tri-clamp discharge arm with butterfly valve;

Dry hopping port with hops adding device;

CIP arm with 360°coverage CIP spraying ball;

Thermowell with high accuracy temperature sensor: PT100

Ice water pipe: PPR or stainless steel pipe as option;

With ice water pipe insulation;

Carbonation device for CO2 is option;

Interior Finish: Overall polishing to 0.4~0.6μm with passivation finish.

3. Parameter of beer fermenterParameter of fermenter

4. Packing & shipping

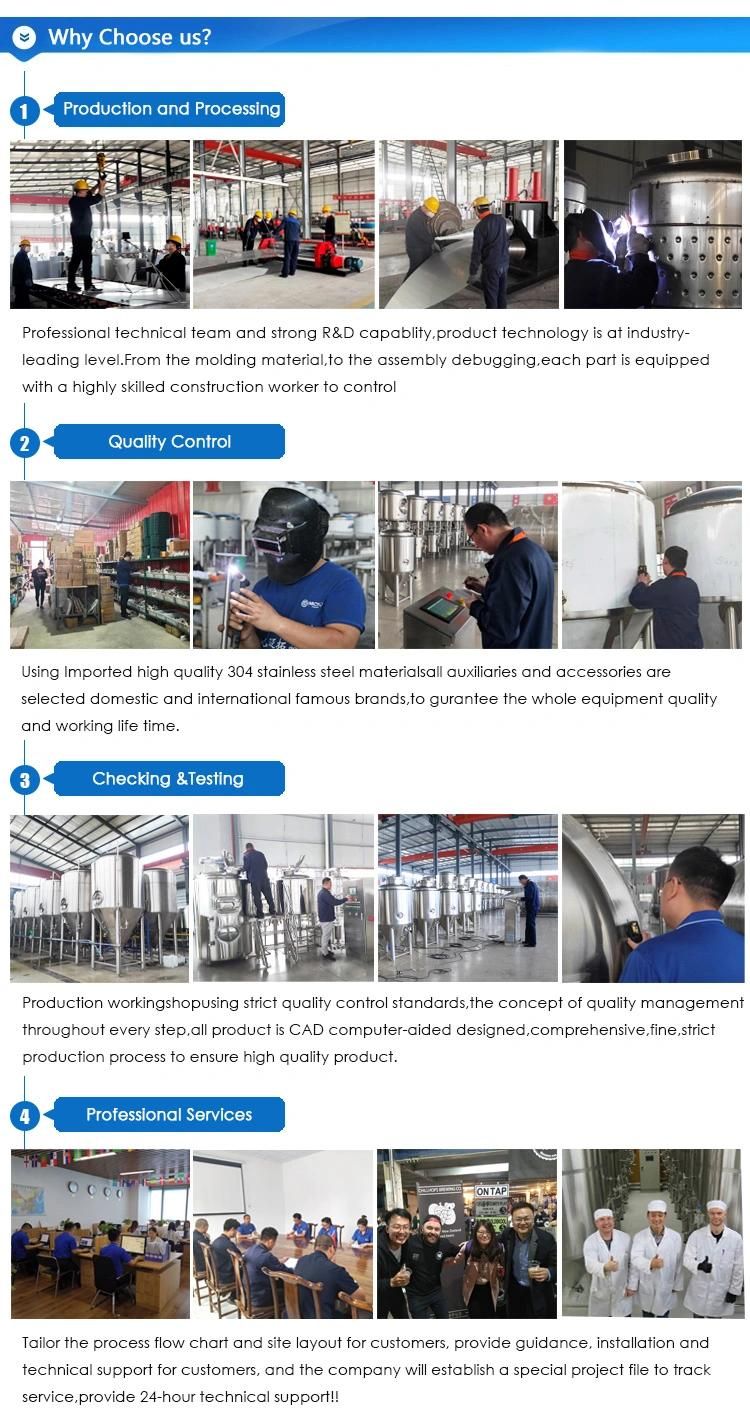

5. Company Introduction

6. Our service

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23