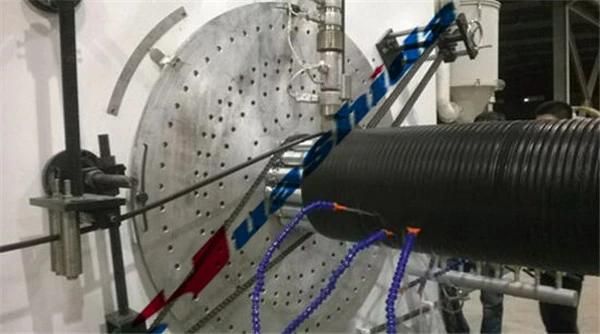

Spiral Wind Drainage Pipe Extruder HDPE Extrusion Line

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SKRG800-3000 Condition New After-sales Service All Life Dimension 26000*16000*5000 Installed Power 380V 50Hz Pipe Range 200mm-2200mm Transport Package Standard Package Specification ISO9001: 2008 Trademark HSD Origin Qingdao HS Code 8477109000 Production Capacity 20 Units/YearProduct Description

HDPE Large Diameter Hollow Wall Winding Pipe Extrusion Line:Application of HDPE Large Diameter Hollow Wall Winding/Coil Pipe:

It has been widely used for sewerage and drainage systems in the city, it will replace the cement pipe, cast iron pipe and other pipes. because low cost of assembling, easy operation, easy connection and economical construction.

Features of HDPE Large Diameter Hollow Wall Winding Pipe

1). High Ring Stiffness

2). High Brunt Intensity and low weight

3). Good creep deformation resistance.

4). Outer pressure resistance.

5). Erosion resistance ( such as acid, alkali and salt etc. )

6). Long life of approximate 50 years. No pollution and so on.

1. HDPE Large Diameter Hollow Wall Winding Pipe Production Line designed with advanced technology includes 1st single screw extruder for square shaped pipe, square shaped pipe extrusion die, vacuum calibration water tank, spray cooling water tank, cutting unit and stack unit. 2nd single screw extruder for melting glue material, spiral forming unit,

2.1st single screw extruder for square shaped pipe and 2nd single screw extruder for melting glue material: Extrusion theory for low energy consumption and low temperature plastic compliant with material characteristic (heavier molecular weight), Unique screw design of distance-changing and separation of solid material and melting material, Unique design of loading system ensures large increasing of extrusion capacity. Special design of high mix-melting ensures through low temperature plastication.

3. Spiral forming unit: Adopts advanced multi-axes transmission box with feature of high transmission force and stable running performance. Unique design of composite die-head, rotational molding after combined feed, and two sets of extruder PE for winding pipe, High quality of winding pipe produced by adopting the unique winding process for pipe forming, The glue extruder can be moved all directions. PLC computer control system with touch screen interface can realize automatic and reliable operation

4. Cutting part: Saw cutting with desired length. SIEMENS PLC computer control system with touch screen interface can effect automatic and reliable operation.

5. PLC computer control system with touch screen: With super high speed and large storage capacity, Multi control points: Forming pipe extrusion, melting PE adhesive extrusion, winding and cutting process can be auto-tail controlled synchronously, Separately controlling two extruder and winding unit in tandem with two touch screens.

6. It includes two parts.

The first part is PE Pipe Production Line. The function of it extrude PE/PP pipe or PE/PP Square Shaped Pipe ( according to your customer requirement ). It include as following equipment:

SJ series Single Screw Extruder / Die Head ( outer mold and mandrill) / Calibration Sleeve / Vacuum Cooling Tank / Spray Cooling Tank

The second part is Forming Machine of HDPE Large Diameter Hollow Wall Winding Pipe. The function of it can produce qualified HDPE Large Diameter Hollow Wall Winding Pipe.

It includes as below equipment: SJ series Single Screw Extruder / Die Head / Spiral forming unit / Cutting Unit / Stack Unit / PLC control system with touch screen

you can go to website: hsdextruder.en.made-in-china.com for more informaiton or email for more information.

Our products mainly include

Single Screw Extruder & Twins Conical Extruder

Vacuum Calibrating pre-insulated pipe outside HDPE casing Extrusion line

20-630mm Single/multi layer HDPE Pipe Extrusion Line

200-3000mm HDPE Spiral Corrugated Pipe Extrusion Line

Fiberglass reinforced PP-R Pipe Co-extrusion line

Plastic Sheet/ Plate Single/multi layer Extrusion Line

PVC Fiber & Steel Wire Reinforced Hose Line

Hand Extruder / Electro-fusion Welder

Heat Shrinkable sleeves (Normal style & Fiber Reinforced style)

Electro-fusion Girth Welding joint closure & Electro-fusion welded bel

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23