1530 2000W Fiber Laser Cuting Machine for 20mm Carbon Steel 8mm Stainless Steel 6mm Aluminum 6mm Brass

Shijiazhuang Lechan Packaging Co., Ltd / 2022-06-23

- Application:Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry

- Cooling System:Water Cooling

- Technical Class:Continuous Wave Laser

- Applicable Material:Metal

- Structure Type:Desktop

- Warranty:3 Years

=== Base Info ===

- Laser Source:Reci,Raycus,Ipg

- Working Area:1500*3000mm(X, Y)

- Laser Head Brand:Raytools Autofocus

- Guiderail Brand:Taiwan Hinwin

- Certification:Ce, ISO

- Servo Motor Brand:Japenese Yaskawa Servo

- Laser Power:1000W 1500W 2000W 3300W

- Cutting Materials:Stainless Steel Carbon Steel etc( Metal Laser Cut

- Running Speed:100m,Min

- Packing Weight:3200kg

- Marketing Type:Hot Product 2020

- Positioning Accuracy:0.01mm

- Repeat Positioning Accuracy:0.02mm

- Production Cycle:20-30 Working Days

- Transport Package:Waterproof Plywood Wooden Box

- Specification:4650*2310*2120mm 3200KG

- HS Code:8456110090

=== Description ===

Product Configurations

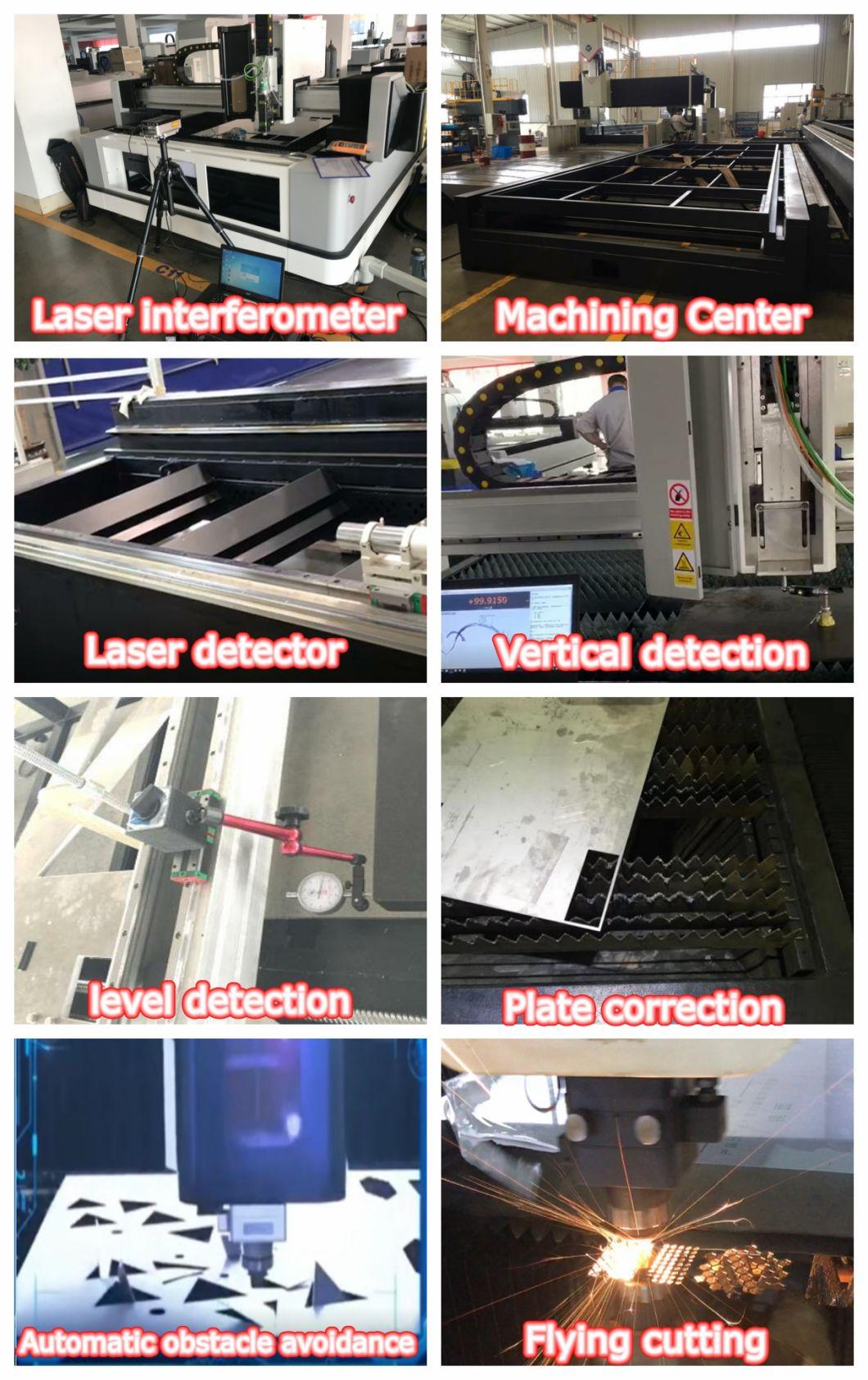

Product Advantages

Our Factory

Packing&Shipping

Step 1.Machine cleaning

Step 2. Wrap all the machine parts with bubble film & plastic film.Insert necessary anti friction & collision

pad at the corner. Set all the small parts on the machine bed to save space

Step 3.

Trailer the full set machine to packing place. Forklift it on the fumigated wooden case.Fix the sticks

on the bottom plywood. Customize wood case according to each model, special groove design, the

bottom of the machine and the top metal structure of the tray is stucked perfectly and prevent the

machine from sliding in the wooden case.Reinforce steel wire outside the wooden case to prevent

deformation of the wooden case. Wrap waterproof cloth outside the wooden box.

Successful Project

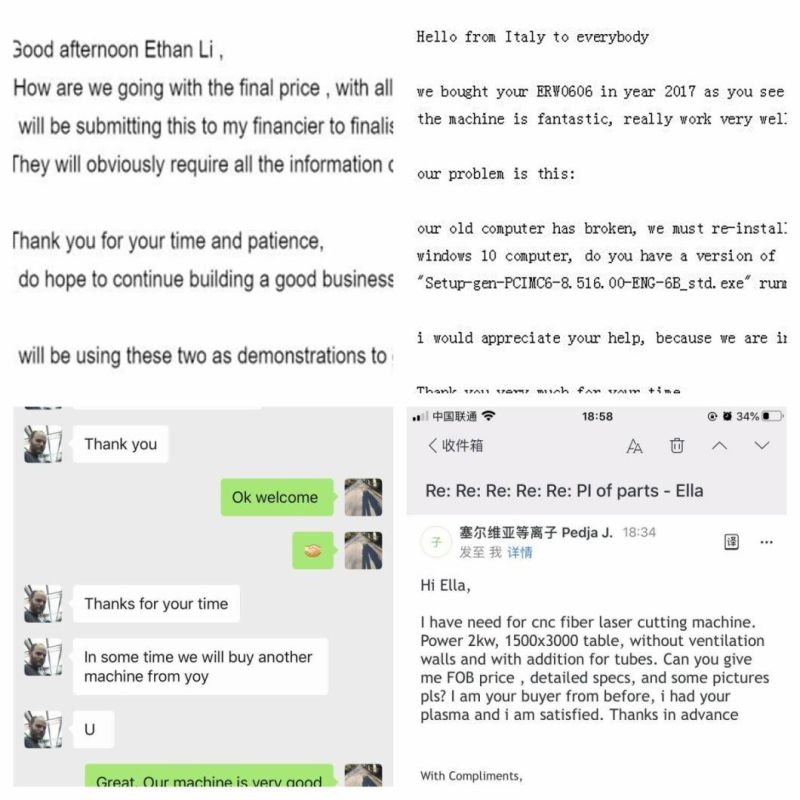

Customer praise

Service

Guarantee Policy:

The guarantee period of quality shall be 3 years counting from the date on which the commodity arrives at the port of destination.Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you(unless some problemed parts need no return). Out of the guaranteed period, should the parts required to be repaired or replaced, if any, ser vice and parts will be charged.

Technology support:

We welcome all our buyers come to visit our factory for directly free training, we will provide our professional engineer to support you study the machine operation. We will supply machine operation manual, training videos and machine cutting parameters, our engineer will supply online machine installation and training.We will send our engineer to the customers' place to help install,test the machine, and to train the customers' technique.

24 hours online service

Customers can keep in touch with our engineer at any time, through wechat/whatsapp/mobile phone or email, our engineer will help to solve your problems.

Exhibition Support

If our agents need our technical support at their show,our engineer will go and work together.

Free Maintenance Service

We provide free maintenance service and technical supports for the fault caused by non-muman factors during the period of warranty; both round turn freight cost (replacement pas and return broken repairable parts). Before maintenance, please show warranty card or invoice to our technician.RFQ

1. Are you the manufacture?Can we visit your factory?

We are manufacturer and we are located in Jinan city of China.And we have our own design team for products design.And welcome you visit our factory and check our machine quality on spot,any question will be solved on spot at first time.

2. what are the advantages of your machines?And how can i believe the quality of your product?

The main configuration is to import quality products, and Professional product quality inspection team ensure machine top-quality, precision and life.For example,Germany ,milling cente,Germany Siemens Main Motor,Schneider Electric system and so on.Once tested as qualified .our machine would be sent out.So The quality of our product is stable and reliable.

3.Payment terms?

T/T, L/C, Western Union, Paypal, Alibaba Secure Payment ect.4.How long is your warranty?

3 years machine parts warranty.During warranty period,we will send you any damaged part for free

5,Are you provide product metal parts and provide us technical guidance?

Wearing parts,Disassembly tool(free) are what we could provide.And we can give you technical guidance.Our technical staff can go abroad to provide you with technical guidance

6.Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service like machine technical.problem or other after-sales problem, meanwhile ,you can get big discount and commission

Contact information

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23