4000bph Fully Automatic Pet Bottle Blow Molding Machine

Hebei Mastek Import & Export Trading Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Bottle type specification

Power specifications

Air pressure specification

Frozen water specification

1.Q:Are you a factory or trading company?

1.Q:Are you a factory or trading company? A:We are a factory

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Taizhou City, Zhejiang Province, China, about 3 hours train from Shanghai by fast train. All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:What is the payment of your machines ?

A:30% by T/T as down payment, 70% by T/T or L/C before shipment

4.Q:What is the delivery of your machines ?

A:30 days after down payment and drawing comfirmed

5.Q:How does your factory do regarding quality control?

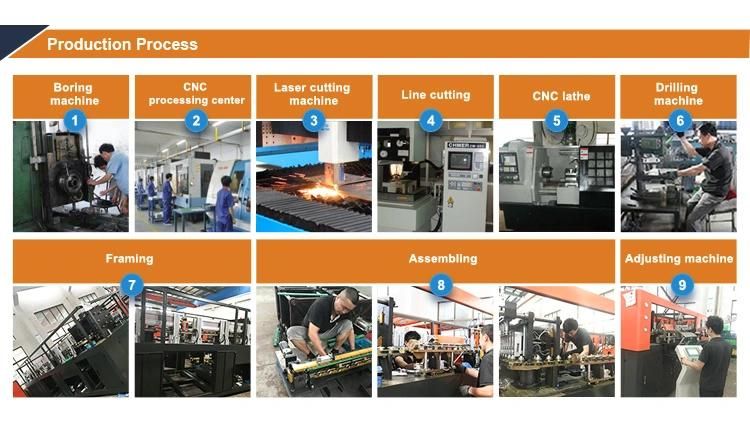

A:Quality is priority. ZS People always attach great importance to quality controlling from the beginning to the end.

6.Q:How about after sales service?

A:One year spare parts for easy broken parts, long term technical support, as customer demand, sending technicians to custoemr site for instatllion or trainning. at importance to quality controlling from the beginning to the end.

l. Special design,high rigid compound die structure

2. Wide adaptability, suitable for every type mould thickness

3. Adjust convenience

4. No mould rolling out

5. More energy conservation,no need much air supply

6. High burnish principal axis, with very precise polishing, light action and low noise.

7. Short mould stroke,quick action

8. All ZG45 casting, with long timing process,very small transformation,can meet your precise request 100%

9. Hig dead-weigh, ensure the steady during the opeartion

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23