Stainless Steel Steam Heating Jacketed Blending Mixing Tank

NINGBO HAISHU JUDIN PACKING PRODUCTS CO., LTD. / 2022-07-05

- After-sales Service:Online Service

- Warranty:One Year

- Usage:Biscuit, Cake, Pizza, Bread, Food Industry

- Power Source:Electric ,Steam ,Gas

- Timing Device:Without Timing Device

- Type:Mixer

=== Base Info ===

- Model NO.:KQ 100L -2000L

- Voltage:220V,380V,440V

- Customized:Customized

- Name:Stainless Steel Steam Heating Jacketed Blending M

- Capacity:200litres, 300L, 400L, 500L, 600L To40000L

- Tank Mateial:Stainless Steel 304 ,316

- Tank Agitator:36rpm to 2900rpm

- Tank Type:Double Jacket, Jacket

- Tank Shape:Conic Bottom, Drum

- Tank Inside Polish:Mirror Polish

- Tank Life Span:More Than 10years

- Tank Design:Standard and Customized

- Steam Heating Tank:with Safe Valve

- Packing:Wooden Box

- MOQ:1set

- Motor:Siemens ,ABB,China Brand

- Cleaning:CIP Cleaning Ball

- Electric Control Box:Yes ,No

- Transport Package:Playwood Box

- Specification:ISO,SGS

- Trademark:KQ

- Origin:Shanghai, China

- HS Code:8479820090

- Production Capacity:500sets,Month

=== Description ===

Work Volume

Rotating 20,35,50,

100,500

Stepless speed reducer or inverter reducer available

600

HIGH QUALITY

MIRROR POLISHED

COOLING TANK ,

Sanitary stainless steel high speed mixing tank, mixing machine, tank mixer,Blend Tank

Mixing tank, storage tank, heatig and cooling tank

1). SUS316L or SUS304

2). can mix the liquid,fluid

3),Capaciy:100L~20000L

Usage: mixing tank is used in food,beverage,chemical liquid mixing,pharmaceutical mixing,etc.

Volume: 0.5-30m3

Material: SS304,SS316

Design parameters

1. mixing tank with 36rpm mixing speed mixer

2. tank with 60rpm mixing speed mixer

3. mixing tank with 200rpm mixing speed

4. 960rpm mixing speed mixing tank blender

5. mixing tank with 40~200rpm mixing speed

6. mixing tank with VFD

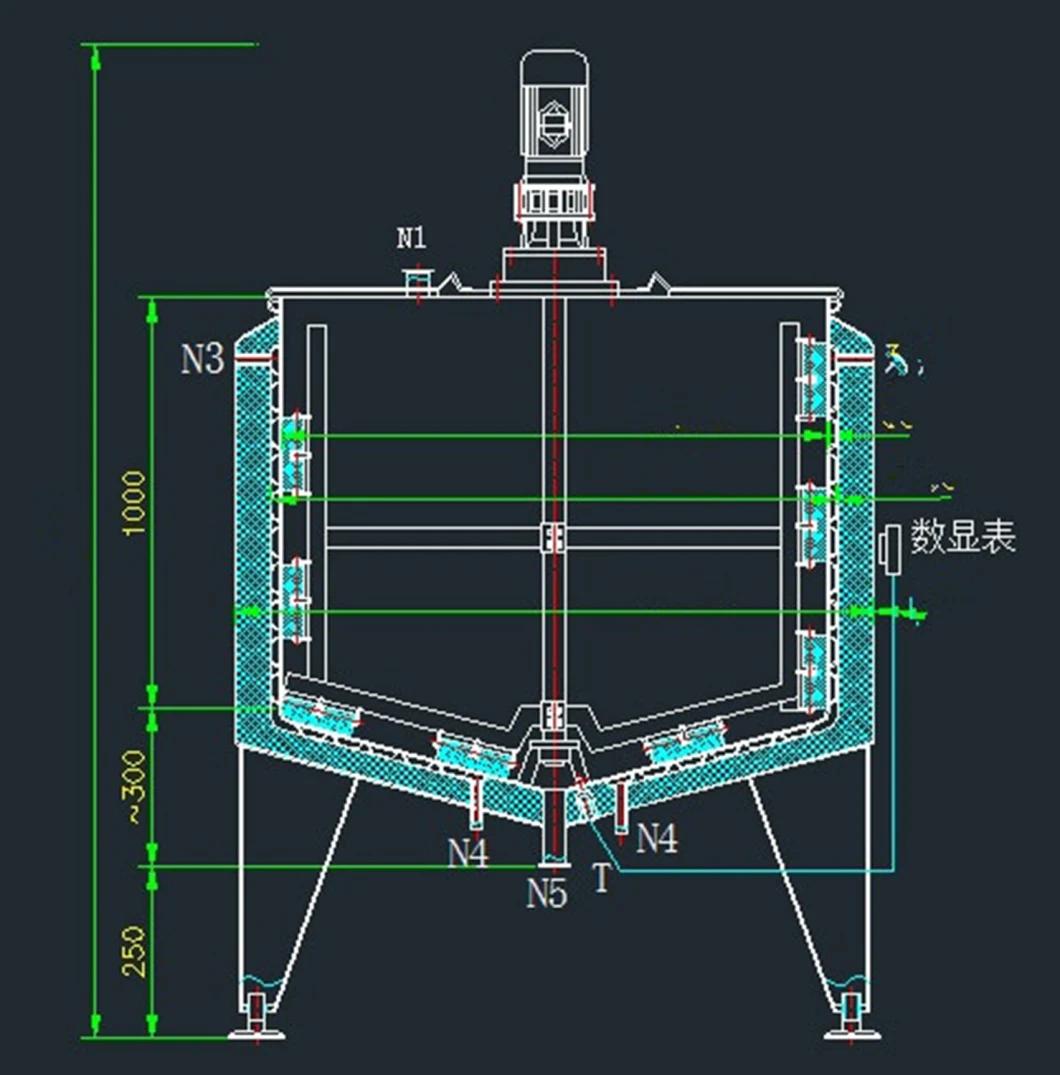

Structure characteristics:

Made of single-layer stainless steel structure, jacketed wall mixing tank, double jacketed mixing tank.

Materials are all sanitary stainless steel, inox,

Humanized structure design and easy to operate.Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation.

Configuration of tank:

1.Quick open manhole.

2.Various types of CIP cleaners.

3.Fly and insect resistant sanitary breathing cover.

4. Adjustable triangular bracket.

5. Dismountable materials input pipe assembly

6. Thermometer (According to customer requirements ).

7. Ladder (According to customer requirements).

8. Paddle blender.

9. Liquid level meter and lever controller (According to customer requirements).

10.Customized and Non-standard products also welcomed .

Stainless Steel Steam Heating Jacketed Blending Mixing Tank

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23