1000 1200mm PVC UPVC WPC Door Panel and Door Frame Making Machine Turnkey Project

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description === (1)Twin conical screw extruder

(1)Twin conical screw extruder

Acccording to different width of door panel, equipped with different mode of twin conical scew extruder.

such as SJSZ-80/156 and SJSZ-92/188

Motor brand is Simens

Frequency inveter is ABB

Omron temperature controller

With auto material feeding and dryer hopper (2)Mould

Including the die mould and calibrator

One mould only can produce one size door panel. If you want produce different size of door panel, please send me message to discuss details, we will offer professional plan.

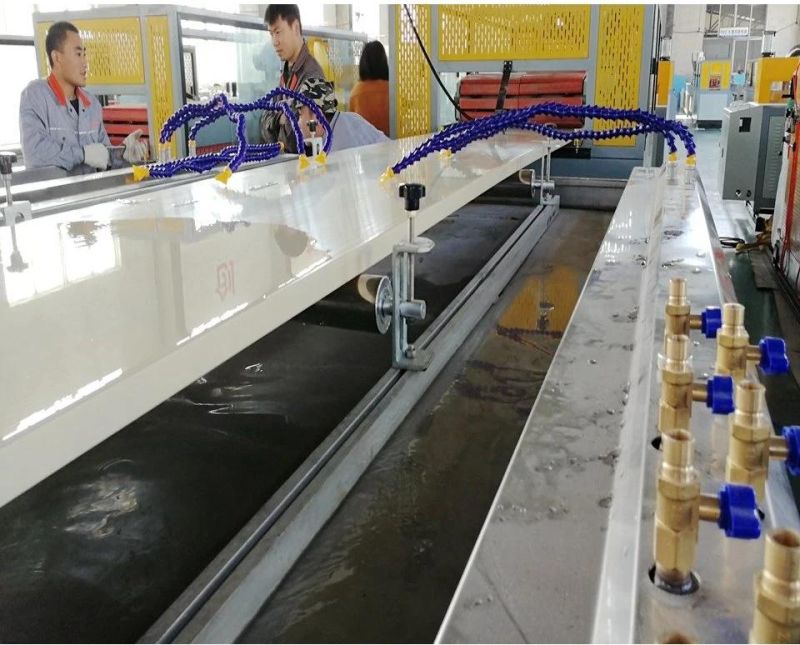

(3) Calibrating table

(3) Calibrating table

According to the width of door panel, the calibrating table can be designed for 6m length, 8m length etc.

The material which connect with water is made of 304 stainless steel. Hual off machine Cutting machine

Advantage of WPC door1, water proof: the WPC door is made by PVC and wood composition, it has the advantage of plastic which is water proof2, fire proof: because of the content of PVC material, the WPC door is fire-proof .3, insect proof: the WPC door will not be damaged by insect.4, no deformation: the WPC door uses hollow structure, so it avoid the deformation problem5, Heat insulation: the WPC door with good heat insulation because of the hollow structure6, noisy insulation: the WPC door with good nosy insulation because the inner is hollow shape.7, no harm to people health: the WPC door is made by PVC and wood powder by extrusion processing, because of PVC melted in high temperature, so it jointed with wood powder without using glue.8, 100% recyclable: the WPC door can be 100% recyclable to be used for making new WPC products.

Advantage of WPC door1, water proof: the WPC door is made by PVC and wood composition, it has the advantage of plastic which is water proof2, fire proof: because of the content of PVC material, the WPC door is fire-proof .3, insect proof: the WPC door will not be damaged by insect.4, no deformation: the WPC door uses hollow structure, so it avoid the deformation problem5, Heat insulation: the WPC door with good heat insulation because of the hollow structure6, noisy insulation: the WPC door with good nosy insulation because the inner is hollow shape.7, no harm to people health: the WPC door is made by PVC and wood powder by extrusion processing, because of PVC melted in high temperature, so it jointed with wood powder without using glue.8, 100% recyclable: the WPC door can be 100% recyclable to be used for making new WPC products.

Other machines for making finished PVC WPC door panel  PVC WPC window and door frame profile extrusion line

PVC WPC window and door frame profile extrusion line

The PVC WPC profile extrusion line is suitable for producing hollow or solid PVC WPC foaming profiles. This profiles have advantages of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof, non-toxic and environmentally friendly. The profiles are widely used in the fields of interior decoration, furniture making, such as door frame, skirting, photo frame, plastic door and window profiles.

Model

| Model | Profile Width | Extruder model | Motor power | Max.extrusion capacity | Calibrating platform length |

| HGMSC-200 | 200mm | 51/105 | 22kw | 100-120kg/h | 4000mm |

| HGMSC-300 | 300mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSC-400 | 400mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSCD-300 | 600mm | 65/132 | 37kw | 150-180kg/h | 8000mm |

| HGMSC-600 | 600mm | 65/13 or 80/156 | 37 or 75kw | 150-350kg/h | 6000mm |

PVC WPC door panel extrusion line is for producing preparatory PVC WPC door panel. We can provide the turnkey project for integrated door panel and door frame. The whole production line includs the PVC WPC door frame extrusion line. WPC door panel extrusion line and subsequent processing equipment. The PVC WPC door has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and environmentally friendly. The PVC WPC doors can be widely used in interior doors, hospital ward doors, school classroom door, various styles can be customized.

PVC WPC door panel extrusion line is for producing preparatory PVC WPC door panel. We can provide the turnkey project for integrated door panel and door frame. The whole production line includs the PVC WPC door frame extrusion line. WPC door panel extrusion line and subsequent processing equipment. The PVC WPC door has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and environmentally friendly. The PVC WPC doors can be widely used in interior doors, hospital ward doors, school classroom door, various styles can be customized.Technical data:

| Model | Profile Width | Extruder model | Motor power | Max.extrusion capacity | Calibrating platform length |

| HGMSC-200 | 200mm | 51/105 | 22kw | 100-120kg/h | 4000mm |

| HGMSC-300 | 300mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSC-400 | 400mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSCD-300 | 600mm | 65/132 | 37kw | 150-180kg/h | 8000mm |

| HGMSC-600 | 600mm | 65/13 or 80/156 | 37 or 75kw | 150-350kg/h | 6000mm |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23