Parallel Twin Screw PVC Floor Spc Floor WPC Floor PVC Foam Board Making Machine

Forsun Ultra-hard Material Industry Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ92 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized High Tech PLC Control System Eir Online Higher Than 95% Motor Siemens or Weg or Sew Calender Five Roller Capacity 25-32 Tons/Day Certificate CE, SGS, UL, TUV, CSA, ISO Convertor Siemens or ABB Voltage 220-415V / 50-60Hz 3 Phase Power 485-750kw Per Line Extrusion Line Layout 35m (L) * 5m (W) * 5m (H) Transport Package Fixed Suitable for Long-Distance Transportation Specification SJSZ110 Trademark BOYU Origin Wuxi, China HS Code 8477209000 Production Capacity 30 Lines/MonthProduct Description

BOYU SJSZ110/220 Conical Twin-Screw SPC Flooring Extrusion Production Line

SPC flooring is considered as the new generation of floor covering with the features: Environmental, extremely stability, high performance, completely water-proof, high density sold core, indentation resistance, anti-skid etc.

Taking advantages of its practical, affordable and simple features, this stone plastic composite vinyl flooring is widely used for home, office, school, supermarket, stadium and hospital etc as the ideal decoration material.

1,SPC Flooring specification

- SPC means: Stone plastic composite

- Main ingredients: PVC powder, CACO3, other processing accessory ingredients (stabilizer, lubricant, modifier, pigment etc.)

- Density: 1.9~2.1g/cm3

- Slab dimension: Thickness: 2-9mm EIR thickness: 3-6mm

- Shrinking percentage of SPC floor:≤1‰(to be treated by tempering) :≤2.5‰(not to be treated by tempering); Test standard of shrinking percentage: 80ºC and 6 hours.

| No. | Items | Data |

| 01 | Operation Conditions | customized |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant, modifier, pigment etc |

| 03 | Main material proportion | PVC: CACO3= 1:3 |

| 04 | Product specifications | Width:1050/1350mm, Thickness:2-9mm |

| 05 | Quality standard | Twin screw standard: JB6492-2001 |

| 06 | Machine Fabrication Certificate | CE/ UL/ SGS/ CSA/TUV/ISO |

3,Equipment List

Extruder → T-die → Calender → Oil temperature controller → Traction machine → Cutting machine → Automatic flipper & Stacker

| Item | Specification/Brand | Unit | Qty |

| Extruder | 110/220 conical twin screw | Set | 1 |

| Mould (width 1050mm or 1350mm ) | Jingwei | Set | 1 |

| Five roller calender | Set | 1 | |

| Film air expanding unwinding laminating device | Double station | Set | 2 |

| Edges trimming mechanism | Set | 1 | |

| oil temperature controller | Four Unit Control | Set | 1 |

| Air curtain | Set | 1 | |

| Cooling bracket | Set | 1 | |

| Traction machine | Two rollers | Set | 1 |

| Automatic cutting machine | Set | 1 | |

| Automatic Flipping & Stacking Machine | Set | 1 | |

| Electric Control System | PLC+HMI | Set | 1 |

| On-line embossing system | Set | 1 |

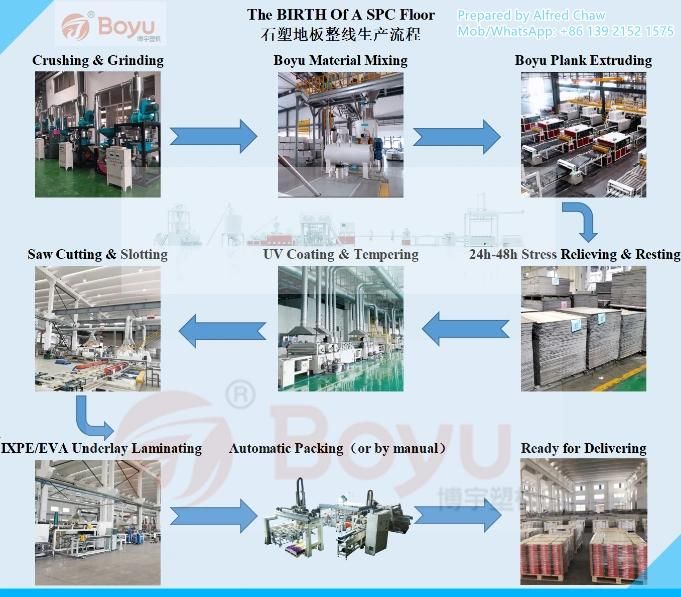

Material mixing → Extruder → Calender→ Cut-to-length →Stacking →UV coating →Saw cutting →

Click slotting →Backing lamination →QC inspection → Packing

5,Extruder model

| Extruder model | Capacity/24h | Capacity/h | 4mm Linear Speed |

| SJSZ-80 | 6-8T | 250-350KG | 0.4-0.6m/min |

| SJSZ-92 | 12-18T | 500-700KG | 0.8-1.3m/min |

| SJSZ-110 | 25-32T | 1000-1350KG | 1.8-2.4m/min |

| SJSZ-180 | 90-120T | 3000-4000KG | 5-9m/min |

| Extruder model | Capacity/24h | Capacity/h | 4mm Linear Speed |

| SZJP-115 | 20-30T | 800-1250KG | 1.5-2.5m/min |

| SZJP-138 | 30-35T | 1250-1450KG | 1.5-3.0m/min |

| SZJP-160 | 50-70T | 2000-3000KG | 4.0-6.0m/min |

7,BOYU EIR Patent

Five-roller calender:

The specification of cylinder is 4×Φ450mm and 1×Φ600mm, the width L=1500mm, one of the cylinder is silicon roller, others are made of high quality seamless steel tube; the roller surface is treated by quenching, and the hardness of base material is higher than HRC50 degrees. The inner tank structure is of reinforced type, the inner tank and the expansion cylinder are matched by heat sleeve, to ensure the strength of roller surface. Then it is hard chromium plated, polished.

Five-roller frame: steel plate welded and tempered.

The transmission unit: adopts the independent transmission, horizontal speed reducer,SEW , variable frequency motor power is 2.2KW of Siemens.

Rotating joint: 5 pieces of 1.5-inchrotary joint, Tengxuan of China.

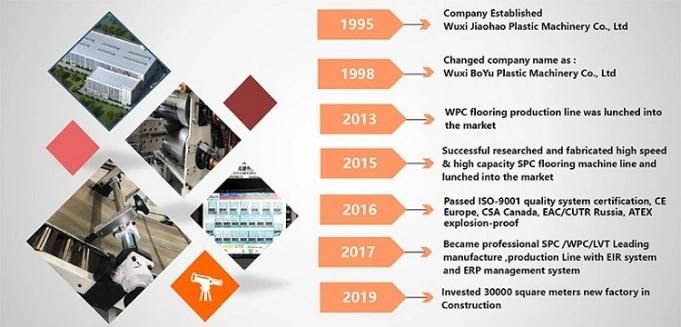

8,Boyu Development

9,Our Services:

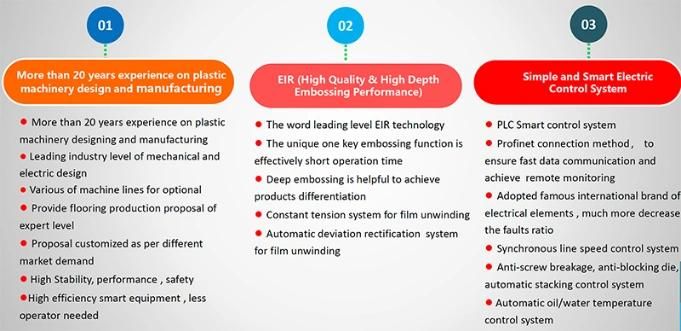

10,Advantages of BOYU Production line

11,Shipping

12, Boyu Project

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23